Posted by andrew lyner on 08/10/2018 12:57:41:

I need to be able to mill the occasional slot and rebate in (as far as I can predict) aluminium. The sort of jobs will be appropriate for a Super Mini Lathe.

I am looking all over – including my Metal Workes's Data Book and this Forum and the longer I look, the more information I am getting – on a divergent path at the moment. I can't decide which way to go.

If I only need a small range of end mills then is there any reason not to buy an MT3 direct collet of a particular size and then use only end mills that will fit in that? Is the advantage of an ER system just that it is easy to swap tools? eBay and other places are just bombarding me with options.

I am further confused by the discussions about tapping the drawbar to release the collet. If it is a real cause for concern then how come there is not (apparently) a system on offer which would include a draw bar and release mechanism? Engineers have been extracting tools and collets for hundreds of years. What could have changed?

I'm not surprised you're a bit confused! What you're planning is a little off the beaten track.

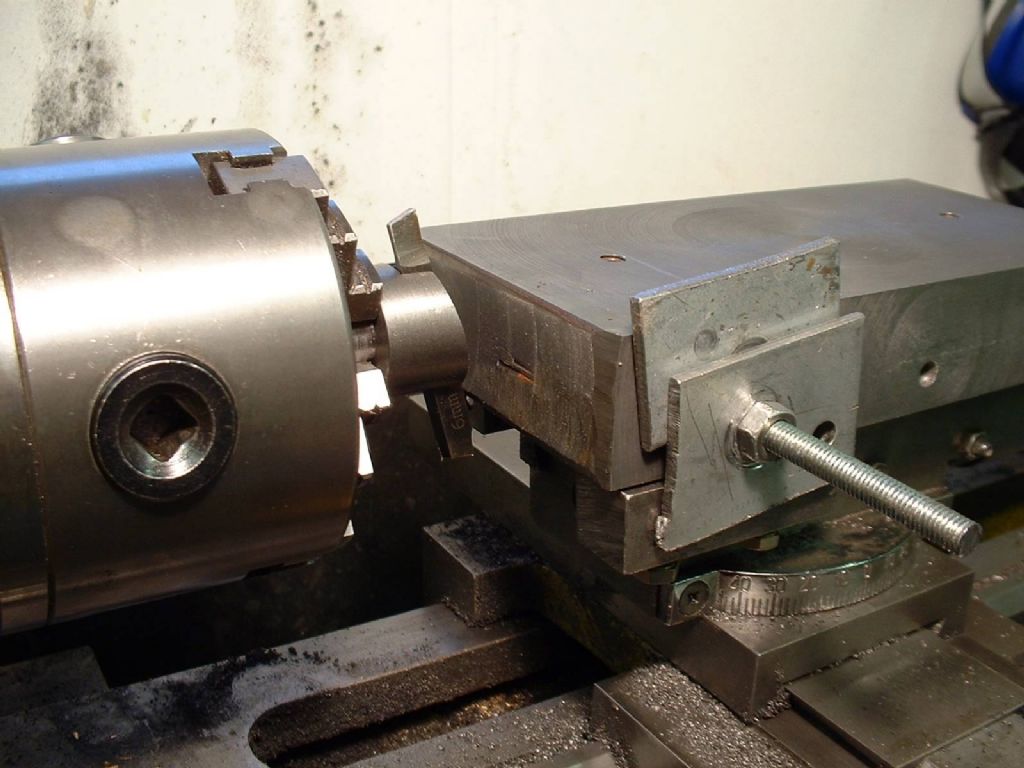

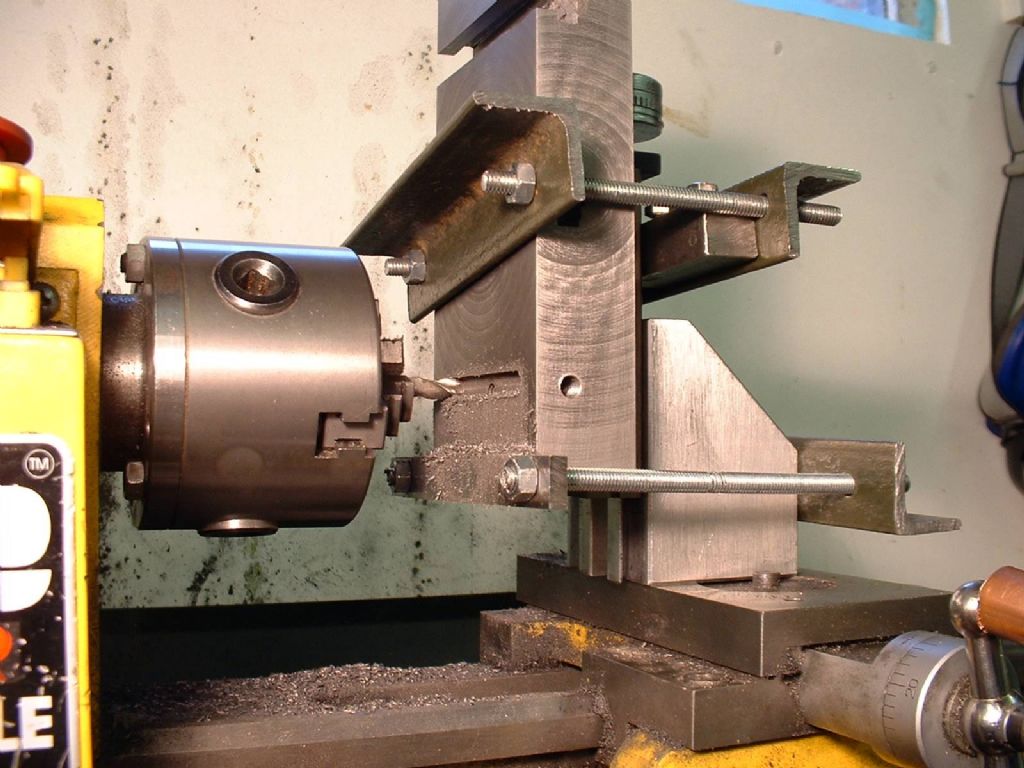

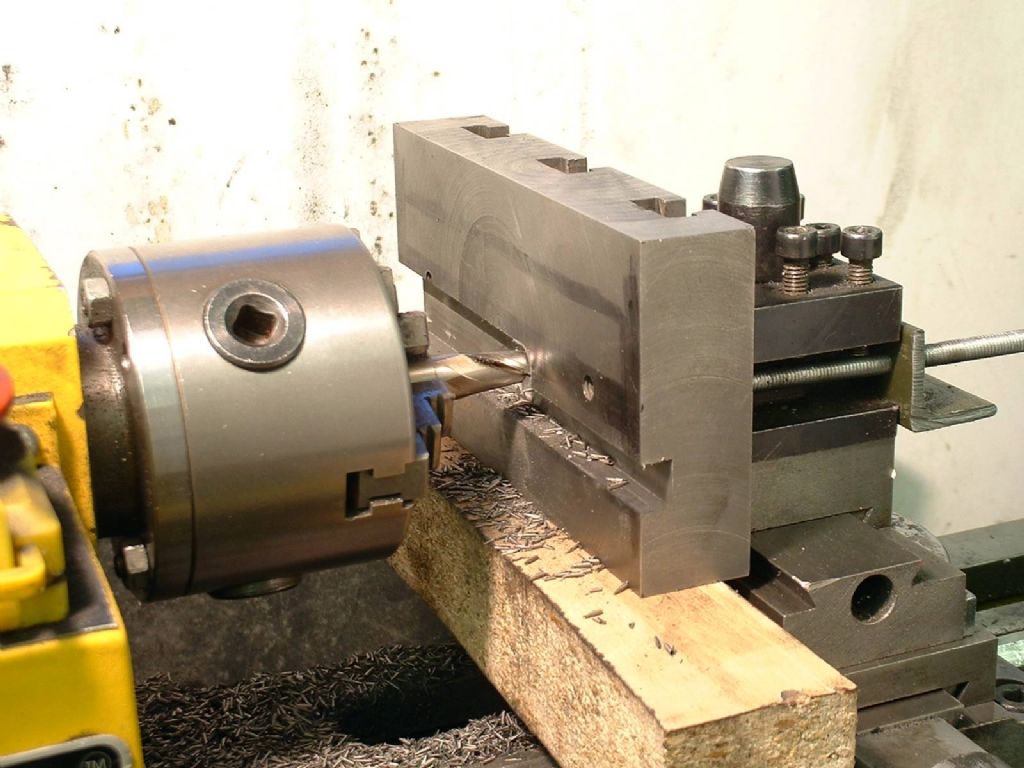

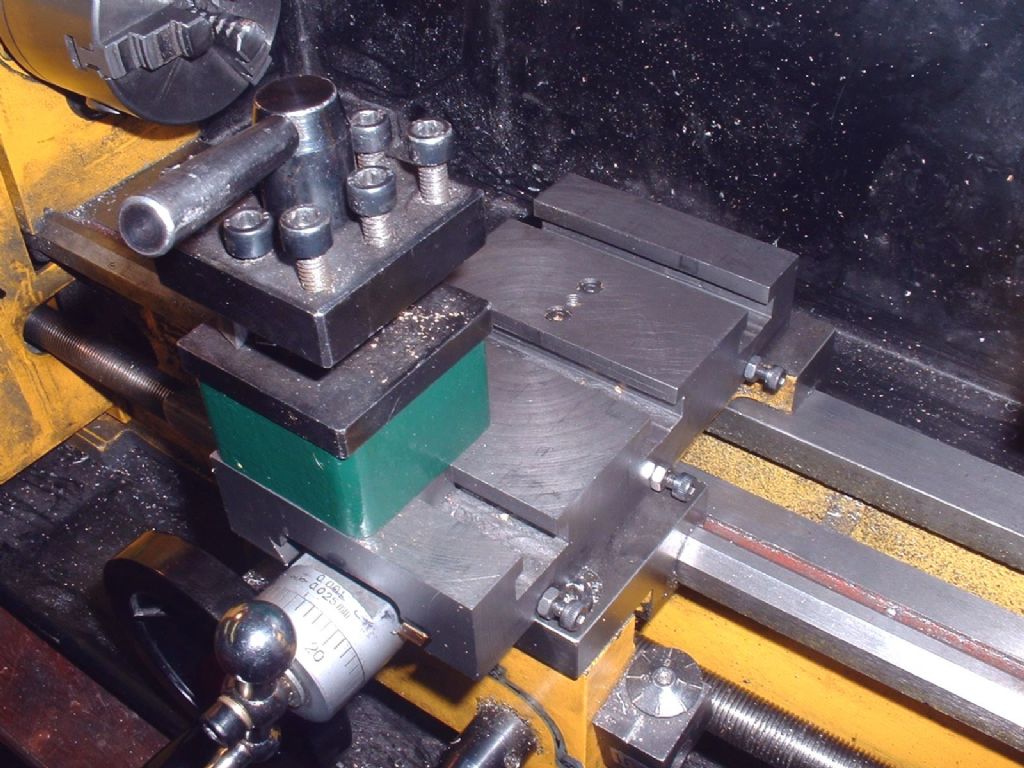

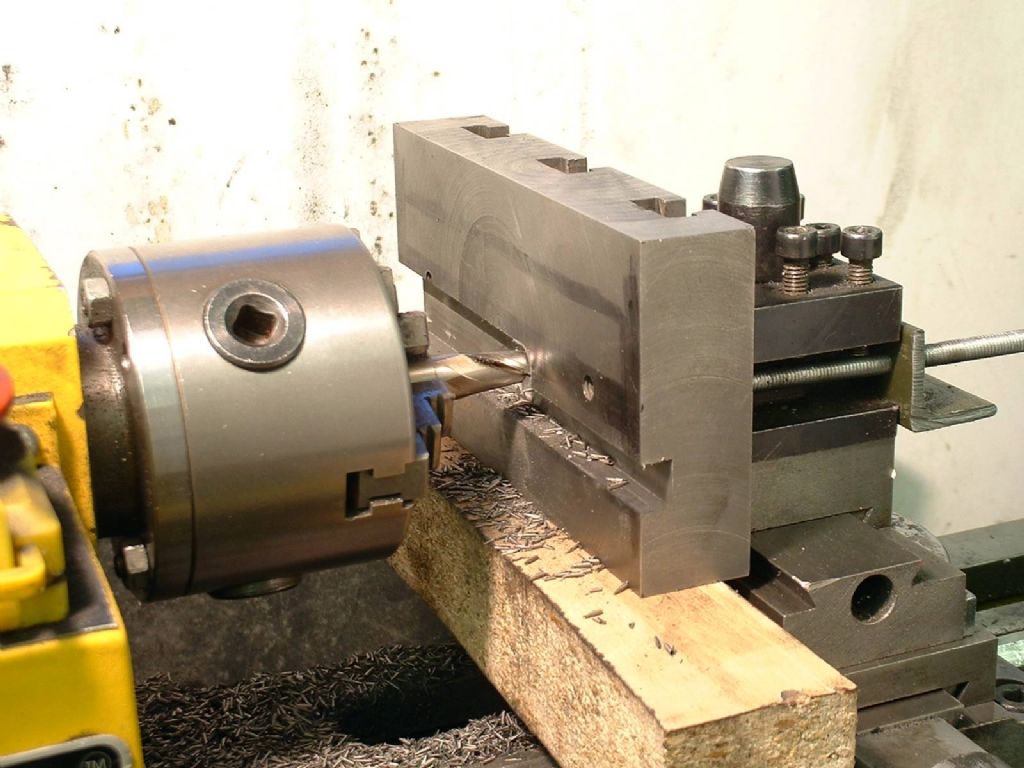

Firstly, although milling on a mini-lathe is certainly possible, it's far from ideal. My experience was quite frustrating – the tool-post has to be unbolted and replaced by a milling vice. Then work has to be clamped on a smallish milling vice after which the length of cut is restricted by the distance the lathes saddle can move front to back. Also the rate at which metal can be removed is constrained by the lathes lack of rigidity.

One awkward decision is how best to hold the milling cutter. I simply used the 3-jaw chuck. Normally a 3-jaw isn't a good way to hold a milling cutter, but because milling is already constrained by the limitations of the lathe, it worked well enough in practice. An advantage is any size of cutter can be used.

ER Collets provide a much better grip on the milling cutter, and also reduce run-out. So, on a mini-lathe you could unbolt the 3-jaw chuck and plug an ER32 chuck direct into the spindle. Unfortunately, because the taper is designed for quick-release, there's a risk the chuck will come loose unless nipped in place with a drawbar. You can get ER32 chucks that bolt firmly on to the lathe – these usually require you to turn a backplate to fit them, but don't need a drawbar.

The main problem with collets of any type is that you need one for each size of cutter, and the whole set up soon gets expensive. I tried an MT shanked milling cutter holder – it works fine, but in my case, didn't suit because of the range of milling I wanted to do. I used it without a drawbar and found removing it problematic. (Done with a hammer and rod from the other end of the spindle.) Without a drawbar the stupid things either come loose or stick solid.

Tapers, as you say, were invented to speed up tool changes. The simplest way of holding a taper secure and releasing it is a screw-in drawbar. Plenty of other systems are available at extra cost, but the drawbar has stood the test of time and it's cheap.

Quite a few people dislike the idea of hitting a drawbar to unstick the taper in case it damages a bearing. Actually, provided the drawbar wasn't overtightened, it's not necessary to pound on it. A sharp tap is sufficient and I don't think there's any chance of damaging a bearing. The concern might have a basis of fact in that some chaps believe religiously that anything done up with a spanner should be good and tight, ideally finishing off by hammering on an extender. Tapers only need to be nipped. If overtightened, they do have to be hit hard, and that could cause damage.

For what it's worth, I abandoned milling on my mini-lathe rather quickly. Fortunately I had the money and space for a milling machine. However, with care, practice and a delicate touch it's certainly possible to mill of a mini-lathe. Try holding the milling cutters in the 3-jaw, take gentle cuts, and see how you get on. I think you'll find that you can make it work and that holding the cutter is the least of your problems.

I'll be interested in what others say. I'm no expert because I took the cowards way out!

Dave

Edited By SillyOldDuffer on 08/10/2018 14:17:23

Howard Lewis.