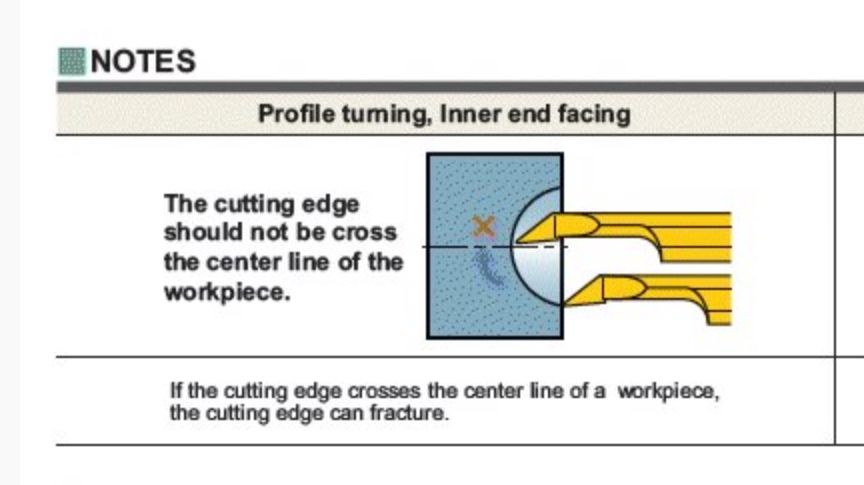

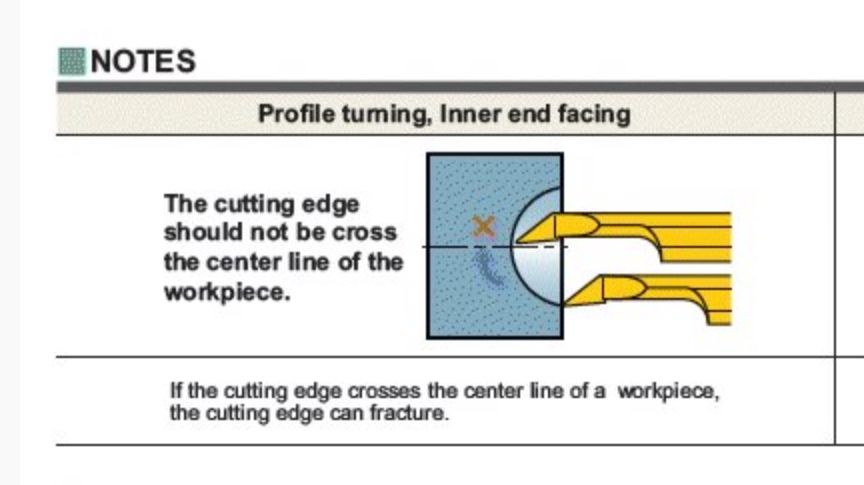

Mike G, The same applies to any turning tool that is rubbed from the reverse. It is worse on a inner sphere as described, you have the work piece acting as a lap over the cutting edge. The above refers to only a solid turned sphere. If there is a small hole or if the bottom of the sphere is formed some other way it is ok. The problem with any small tools is the very centre of any part. As it has zero surface speed, it can only be removed by deformation or by the chisel effect. Very small tools are just not that strong in their geometry and by their nature are weak. That makes them very susceptible to centre line height setting. Often when boring having the tool slightly above centre height is an advantage as the loading of the tool, then deflects down and in doing so reduces very slightly the cutting load. When the tool is exactly on centre line, when it deflects down, it will take a very slightly bigger cut. When it is set below centre line, it will have the tendency to be digging in and taking cuts big enough to either damage the tool, or leave a very poor surface finish. So with small tools, the more rigid the material the tool is and the lighter cuts makes for the tool lasting a long time with good surface finish. Cutting fluids that promote the shearing of the material, ie reduce cutting forces, help a lot as well. On small stuff, I keep the corner radius to less than 0.2mm or 8thou. On micro bars, less than Ø3mm diameter, I have the tool radius at 0.1mm or 4 thou. This allows at a 1 thou per rev feedrate to get accptable surface finishes. If I need a very good finish, I hand feed at about the 0.01mm per rate approx. So when the spindle is doing 600 rpm, I feed the main hand wheel so that I do 1/4 turn every 7 seconds, or 1 rev in 30 seconds. This is for the 0.1mm nose radius tool. With .2mm radius tool it is turning the hand wheel 1 rev per 15 seconds, or 4 revs per minute. The myford box does not allow 0.001 inches per rev feed rate. It takes time to learn to turn a handle at a feedrate, but is really worth while to learn.

Roger Head.