Jason

Mister, Fog Buster and Microdrop aren't really specifically different systems. More different points on a continuum.

The all work by entraining "just enough" lubricant inside an airstream. The lubricant mist / droplets stream should be comfortably inside the actual airstream so the lubricant is surrounded by a "wall" of air helping to control its distribution.

They will all produce an unholy fug if set up wrong with too much air driving too much coolant. My Bjurs can be spectacularly awful!

Generally, whatever the system, if you can see significant drops or fluid layer on the workpiece surface you have too much lubricant. Hafta confess that I run my modified Bjurs a little too rich but the overbored nozzles produce bigger, more like fog buster, droplets.

Oversimplifying

So called mist systems, more of an aerosol than true atomisation, produce the smallest droplets in a distribution which doesn't need to spread out much to cover the cutting area. Theoretically you can operate at lower pressures to, theoretically, have no bounce back. Supposedly the very small droplets instantly wet the surfaces and shouldn't be blown off by the airstream so the lubricant pretty much stays on the work and tool. Drawback is the low inertia of the tiny drops so the nozzle has to be close to the job to work at low pressures. At longer distances the aerosol tends to spread past the work.

Its very difficult to see when you have the required tiny amounts of entrained coolant so its tempting to open up the air and lubricant feeds so you can really see whats happening. Usually blasting huge amounts of mist past the job into the shop atmosphere for instant fug. Plenty of adjustment so plenty of opportunity to get it wrong.

Fog Buster basically uses a larger nozzle than mister so bigger drops are produced which carry better and don't spread into the air so easily. Being bigger the drops don't wet and spread quite so easily over the cut and tool so you may need a little more lubricant. But the higher inertia of the bigger drops makes it easier to control the distribution in the air stream so they carry further than mist without spreading out dangerously. Much more tolerant of variations in nozzle to cut distances and the bigger drops are easier to see. Too much air and too much lubricant leads to bounce back and drops being blown past, or off, the workpiece into the air where they break up into fug. The big advantage of a (DIY) fog buster is that its simple to make and pretty tolerant with a reasonably wide spectrum of "works well enough" conditions. The bigger drops make it easier to see whats going on and its pretty obvious when the set up is wrong.

Fog buster set-ups tend not to be very versatile. Lubricant to air ratios tend to be pretty much fixed by design. Which can be a limitation for industrial use. Great for DIY because, if you make it to design, it does what it says on the tin. Someone else has already done the hard work of figuring out a set up that works well enough. Generally you have to work quite hard to produce a fug.

Micro drops release small, individual, droplets into the centre of a well defined airstream. With truly independent control of drops and air they can be set-up to specifically match exactly what is needed for any given cutting conditions and nozzle orientation. Effective, versatile and expensive but, if you are determined they will still produce an unholy fug.

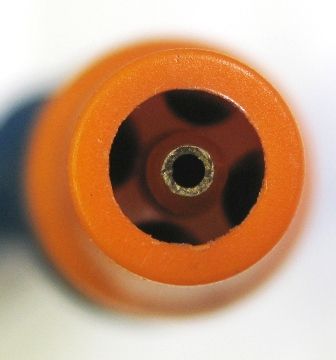

Opening out the exit nozzle on a Bjur system gets quite close to Fog Buster performance.

Clive

Edited By Clive Foster on 06/02/2021 11:43:46

noel shelley.

![img_20210210_152638[1].jpg img_20210210_152638[1].jpg](/wp-content/uploads/sites/4/images/member_albums/143741/888857.jpg)

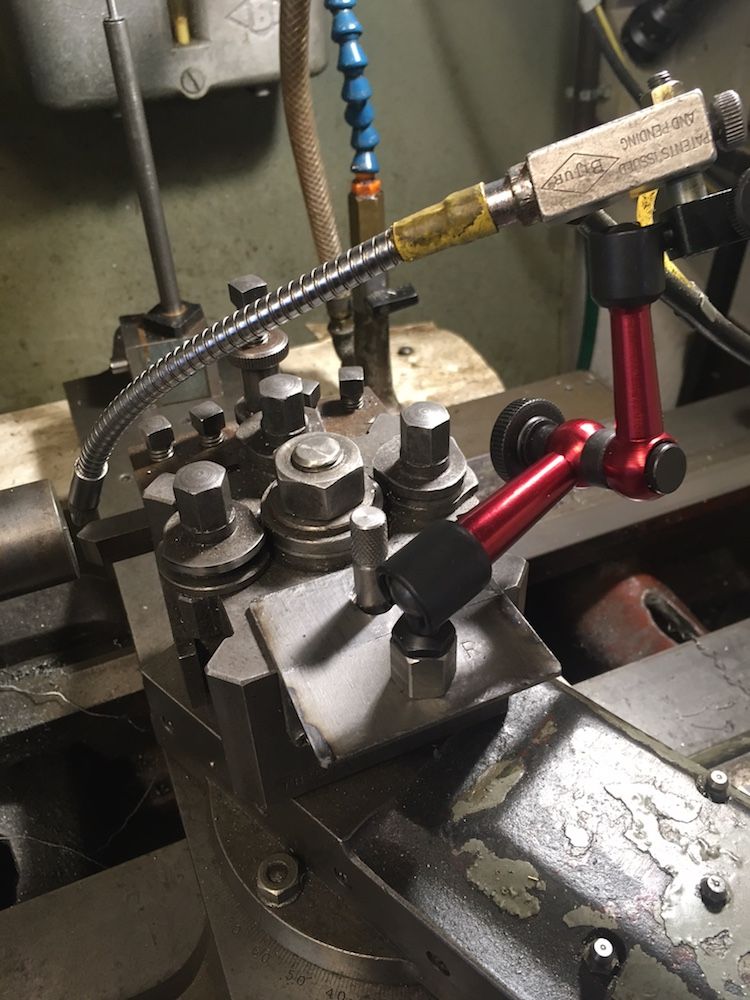

![img_20210210_152624[1].jpg img_20210210_152624[1].jpg](/wp-content/uploads/sites/4/images/member_albums/143741/888856.jpg)