Just a suggestion, but this is one of those questions about achieving a balance. It's about how best to allow wanted steam to flow whilst blocking priming aka foaming, ie unwanted water which reduces performance and can damage the engine.

Priming is caused by sudden demand for steam, dirty water (especially oil contaminated), and too much water in the boiler. Overfilling is one cause, but there's also a temporary effect caused by splashing. Bouncing a model scale engine across rough ground or sudden braking is a likely cause of priming.

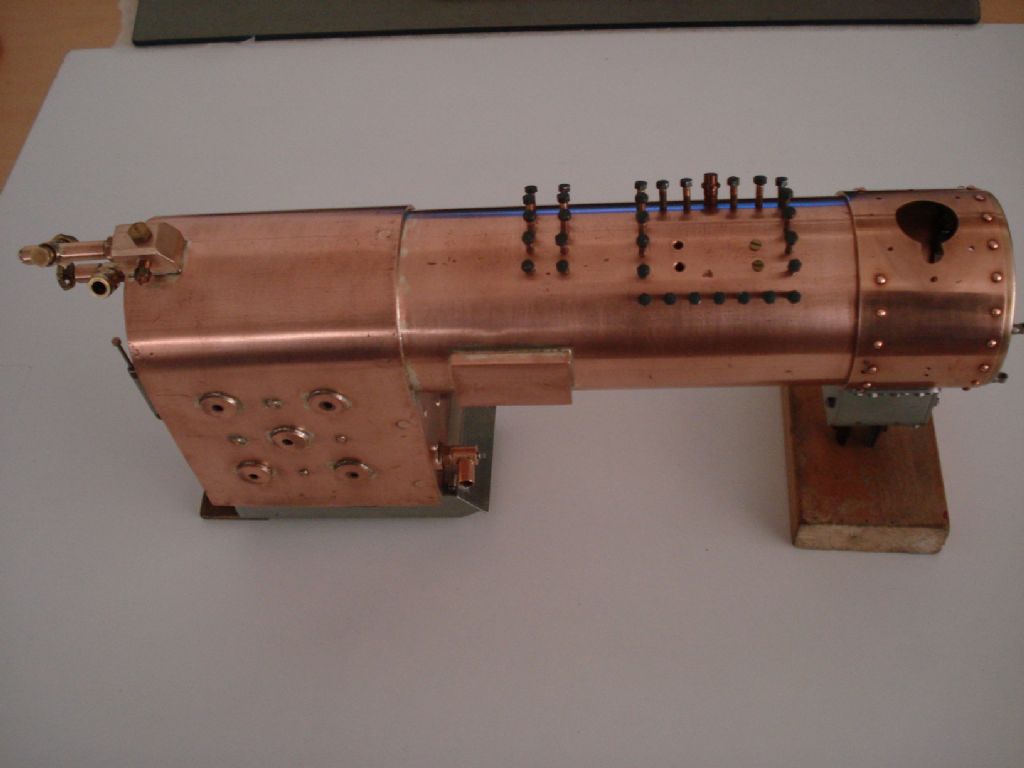

Brian's large single slot solution delivers maximum steam flow. This is best for engine performance but provides no protection against water passing into the cylinder. But anti-priming protection may not be necessary if the engine is carefully filled and driven considerately on smooth surfaces.

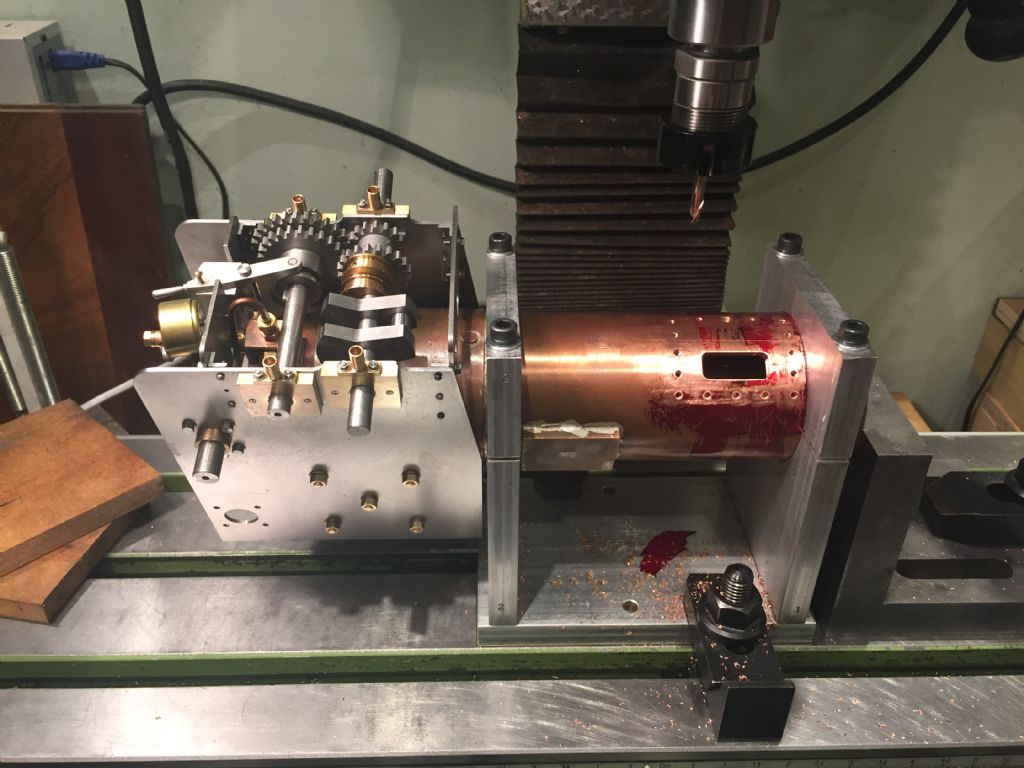

Richard's six 1/8" holes provide much better protection against priming (if that's a problem), but protection comes at the cost of restricted steam flow. His relatively small aperture might throttle steam and constrain the engine's speed and pulling power. Again this might not matter, provided the engine performs well enough on the ground.

Guessing from the photo, Brian's slot is about 1/2" by 1", providing 0.5 square inches of steam access. In comparison Richard's six 1/8" diameter holes provide 0.07 square inches of access, roughly 15% of Brian's, a lot less. Consequently, Richard's engine is more likely to be throttled than Brian's.

Or maybe not! The passages inside the cylinder and valve also limit the amount of steam that can get to the piston, and these passages are likely to be small – less than 1/4" in diameter? There's not much point making a huge steam hole in the boiler when the piston can't use it. Therefore I suggest the total area of the anti-priming holes should be made about twice the area of the cylinder passage, whatever that is. The boiler port being bigger in area than the cylinder passages will avoid throttling while releasing space under the gasket for more smallish anti-priming holes. It should be possible to prioritise steam flow, whilst providing useful anti-priming. (Ideally there would be a shield inside the boiler as well, but perhaps that's more trouble than it's worth. Do model traction engines suffer badly from priming? Perhaps not. I don't know.)

The optimum diameter and spacing of each anti-priming hole is another issue. I guess small diameter holes will be better at keeping out water (good) at cost of increased friction (bad). Thousands of miniature holes would reduce steam flow far more than a single hole of the same equivalent area. I expect the optimum is covered in the engineering literature if anyone can find it! Although once found the theory may not cover small engines.

In practice, because small engines can never be operated as optimally as big ones, the exact diameter and layout of the holes may not matter much provided they allow enough steam out to satisfy piston demand. 1/8" diameter holes feels big to me, while 1/16" feels too small. How about 2.5mm! Your guess is as good as mine…

Dave

Dave Halford.

Dave Halford.