Posted by Ron Laden on 19/12/2018 08:51:14:

The lathe in low range has a bottom speed of 32 rpm but I thought it probably has little torque at that speed and would stall easily.

p.s. I dont know the first thing about thread cutting, I am currently reading up on it but wouldnt it be useful for that.

Your Mini-lathe has a DC motor and they have excellent low speed torque characteristics. (Torque=force applied during turning. Power= force over time. Both characteristics matter.)

DC motors with suitable electronics are much better for powering a small lathe than a single-phase AC motor as fitted to a Myford. Myford lathes use back-gear to compensate for their single-phase motor's need for speed. I expect Myford would have used DC motors had they had the choice. But before modern semiconductors, in homes wired for AC power, powerful DC motors were expensive and inconvenient. Today DC motors are a sensible option.

There is a large fly in the mini-lathe's ointment! Being inexpensive machines, their motors keep themselves cool with fan blades attached to the rotor. If the motor spins too slowly, the fan becomes ineffective and the motor is liable to overheat and burn-out. To reduce the chance of that happening the controller is set so the motor won't spin below a certain rpm.

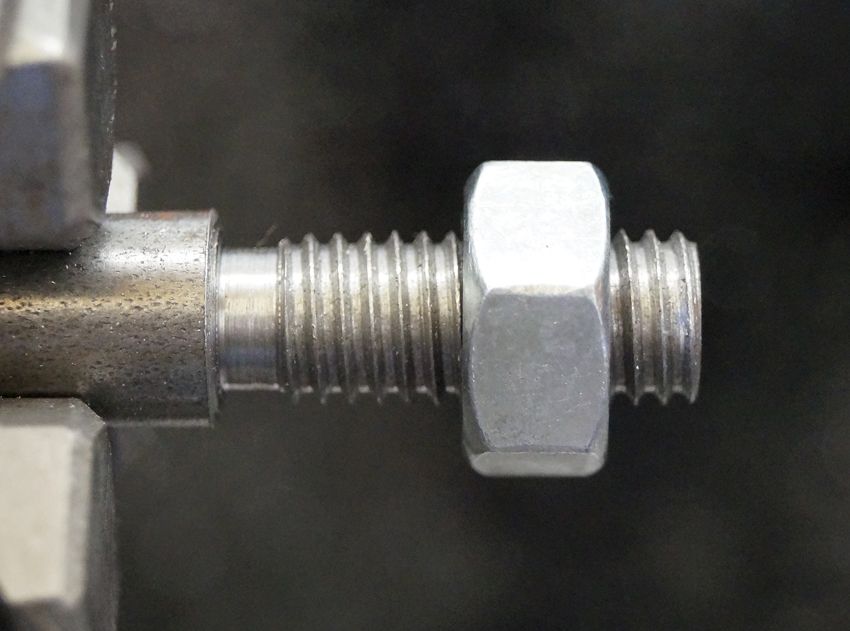

Consequently most mini-lathes won't spin below about 150rpm at the chuck which is uncomfortably fast for the operator when threading. At 150rpm, you have very little time to disconnect the half-nuts before the saddle smashes into the chuck. (Threading as such at 150rpm isn't unreasonable provided the lathe is fitted with some automatic means of stopping. Cheaper machines rarely have such mechanisms. However, Far Eastern types will run in reverse and threading away from the chuck with the lathe in reverse solves the problem.)

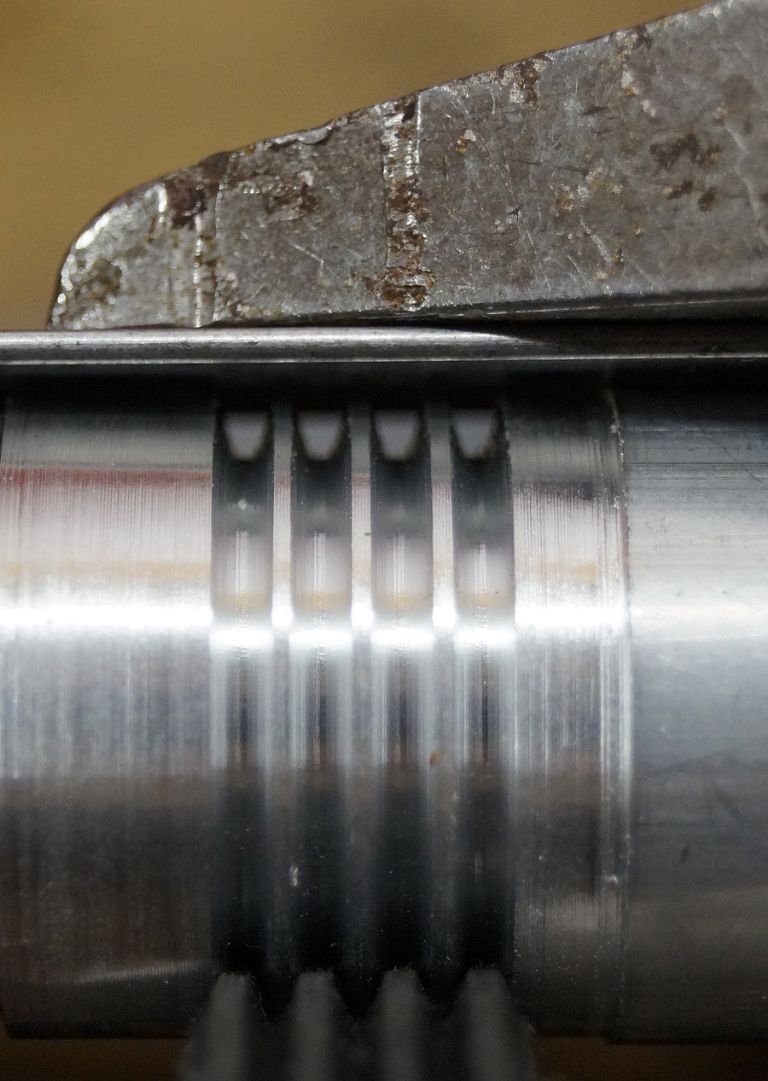

On my mini-lathe almost all threading was done by manually turning the spindle with a hand-crank. It provides total control and is only tiring &/or tedious if you have a lot of threads to cut. The average bloke can easily output a few hundred watts in short bursts. Not so long ago mini-lathe sized machines were mostly powered by treadles.

Dave

Oldiron.