Some interesting comments on this, including one suggesting the lathe should be sent back. I'm far from convinced that all the criticisms are valid, particularly when they address 'faults' that Ron hasn't actually encountered, or compare one way of doing things with another without taking into account the design philosophy.

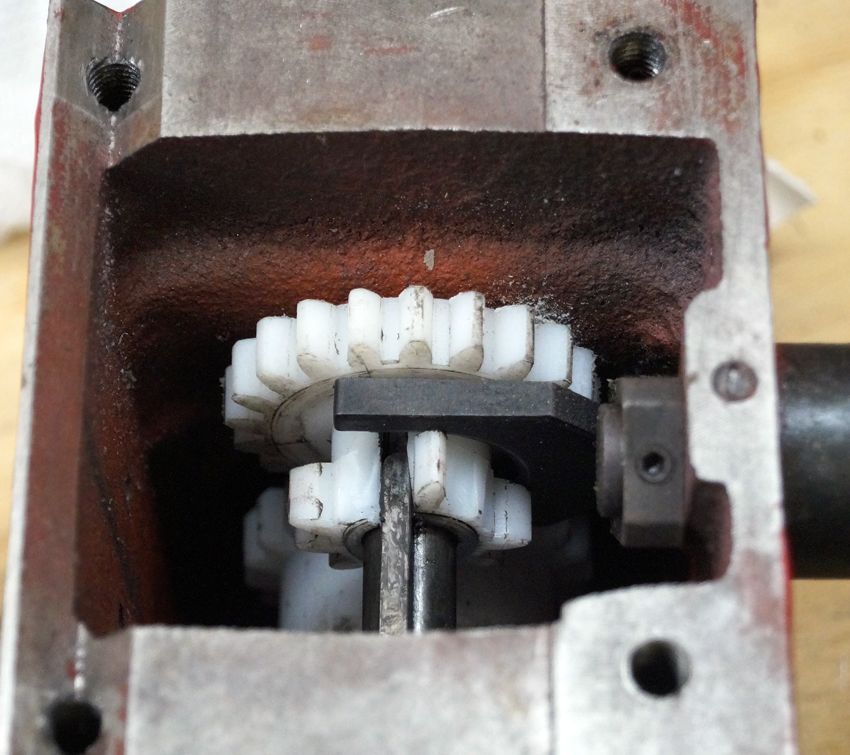

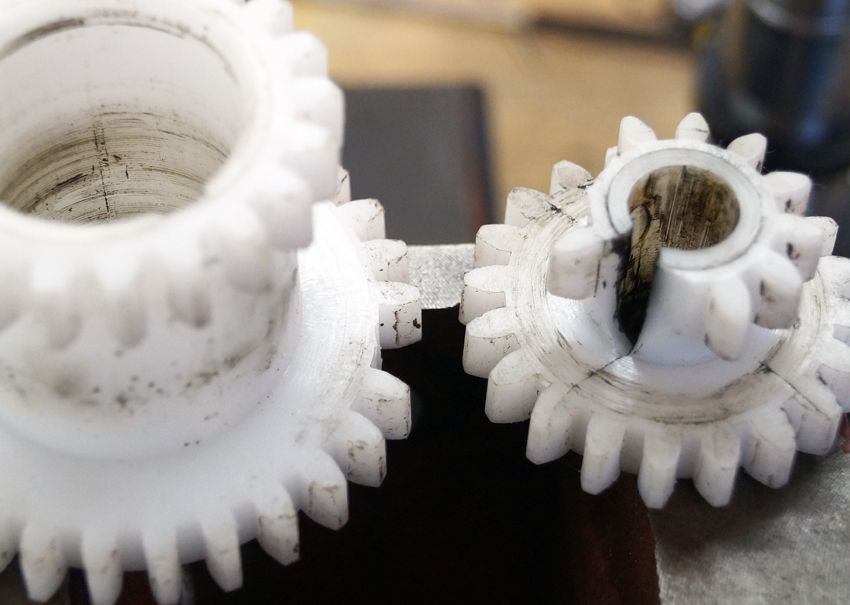

Plastic gears snapping during a crash is a well-known mini-lathe problem. The same gears do not appear to wear out in normal use, and the absence or presence of oil does not appear to cause any problems either. (Unless you know different!) There is reason to believe that the gear – it's always the same one – is deliberately intended to break : it's a mechanical fuse. The design fault is that the gear is inaccessible and takes a few awkward hours to replace.

Are plastic gears only used because they are cheap? I suspect not: a key advantage on a table-top lathe is that they are quiet making it possible to use the machine inside the house. Is oil necessary inside the headstock? Only if your lathe uses old-fashioned plain bearings, in which case it's essential.

Actually what's going on with these lathes is "Value Engineering". This is really what matters in manufacturing as a way of earning a living, not making 'nice' kit. Any fool can look at a design and increase its cost by insisting on the best possible solution to every feature whether or not it's needed. The problem with doing so is that lifting 'quality' increases the cost to the customer. Less obviously, and much more dangerously, inappropriate quality savages profits. Myford fans have to explain why the old company had to cease trading despite their lathes being so good: the answer is in the accounts. Ditto most of the other makes listed in lathes.co.uk Good machines, rotten economics.

It's much more difficult to engineer products that work satisfactorily at a competitive price whilst making a profit. This is more-or-less what the Chinese have achieved with hobby machine tools. The challenge for Western engineers is to produce something better than, say, a Super 7 for under £800 at the factory. No point is whinging about oriental successes – get your act together and out-do him.

Dave

Edited By SillyOldDuffer on 07/12/2018 10:28:36

Oldiron.