George,

I did try that way, but I was either too greedy with the cut or that DIY rotary table is not up to it, so gave up.

Drawbar:

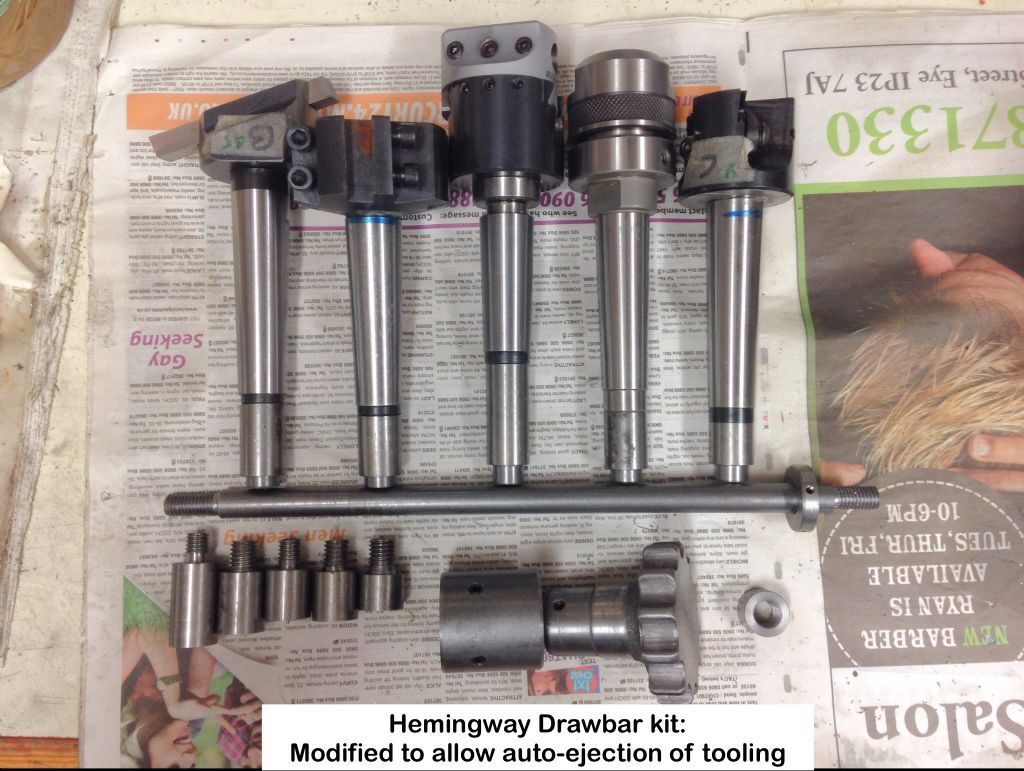

I have just finished it and the photo shows all the completed parts, plus at bottom left, my first attempt at the MT tool extensions that have now been added to the scrap bin.

In my post when I said I had sorted the height of those extensions to allow the use of one drawbar, I spoke far far too soon, with fate giving me a real kick in the posterior.

I could not have made a bigger codswallop even if I tried, and then spent days trying to figure out where I went wrong, but eventually giving up in utter disgust with myself.

That was on Friday 28th November! I know I know, slow coach.

Then on the Saturday I thought (bad move) that I had sussed it out using Touchdraw on the iPad, but no, so retired to recuperate and give the old grey matter time to come to its senses.

Tuesday 2nd of this month brain at last started to operate, and I came up with the perfect solution of determining what length to make those MT tool extensions so that they all reached the same height inside the spindle, when screwed onto each tool.

The method I used can be seen on two of the MT tools in the photo.

Who can see how/what I did?

Will explain later of course if needed.

The handle was finished off using a combination of Excel filing machine, hand file then small grind stone in the battery drill.

The Auto-eject collar is attached to the drawbar, with the spindle cap, that the collar pushes against, and handle below.

All the 3MT tooling is shown at top, each fitted with its specific extension that allows for a single common drawbar to be used.

It took a little trial & error to get it to eject the 3MT tool, but does so now with about a 1/10th turn of the bar.

All I can say is that the time and angst this has caused me has proved well worth the effort, and I can recommend the system without reservation.

Now need to do one for the Tom Senior horizontal arbor.

Geoff – It feels good when something comes to a satisfactory conclusion

OuBallie.