A while back I bought off ebay a "Rapid Original" QC tool post for my Boxford ME10 lathe, it came with one tool holder.

I thought it would be a nice project to make some more, I decided to make four more, here is a photographic record of how I did it,

The block as bought,

I had some steel offcuts, 3" x 1 1/2"x 2" in stock, the tool holder I had was, 3" x 1 1/4" x 1 3/4", so I used the Elliott 14 M shaper to reduce the blocks to size.

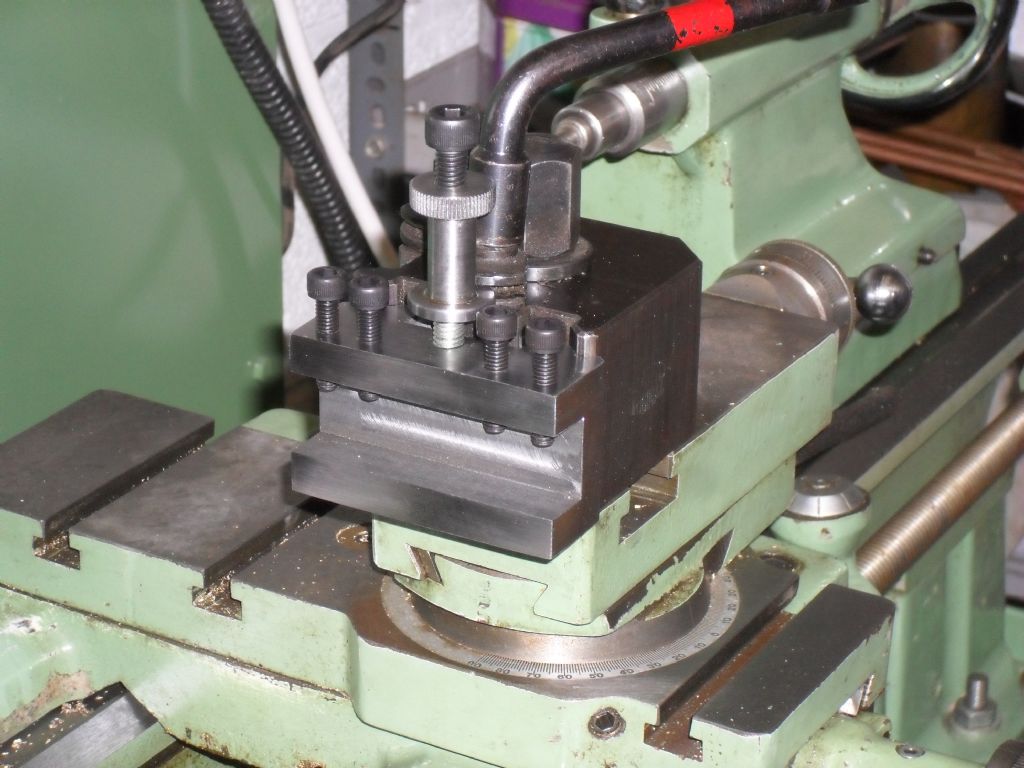

Then I had to machine the main part of large "T" into the back of the blocks, for this I used a 1" endmill in the TOS FA3A mill

Next I had to machine the "T" of the T slot with a 1"Dia x 1/4" Woodruff cutter, Each side of the "T" was cut in one pass, , 0.145" deep, at 250 RPM and a table feed of 20mm a minute.

Cutting the second side,

Now to cut the "V" slots, to start I cut two slots 0.093" wide into the blocks 0.300" deep, x 2.437" apart centre to centre, this was to give the points of the "V" cutter an easier life, I used a 4" x 0.093" slitting saw in a Tom Senior M1 horizontal mill.

Then I cut the "V" slots on the same machine using a 90 degree horizontal cutter,

After a bit of tidying up, I then machined the large slot for the lathe tool to clamp into, using a 3/4" 3 flute slot drill,

Opening out the slot to 0.850" wide x 0.550" deep

Next I made the height adjusters from 7/8" Dia, steel, with a straight knurl, threaded 8mm,

Here are the 4 adjusters completed,

Here are the four tool holders ,assembled , with 6mm tool holding screws,

And fitted to the Boxford lathe,

This was a nice engineering project, that will make the Boxford lathe a lot more pleasant to use.

I am quite a shaper fan, I think it would be fun to produce one of these tool holders entirely using a shaper, ( not drilling the holes of course ),

Richard.

Edited By RICHARD GREEN 2 on 14/10/2016 20:04:48

Emgee.