Purchase of a proper DRO system having effective PCD and other functions has to come before investing in a rotary table unless you have some very rotary table specific needs.

Most good DRO systems also have a curve generating function using multiple small X & Y feeds. Redefines the concept of mind numbing as you are basically doing CNC the manual way but it gets the job done. I have to admit that the couple or three times I've done a curve that way the time taken wasn't vastly different to what would have been needed when using a rotary table given the time needed to swop the vice for the table. Curves were something around 1/3rd of a circle I think. One of the times when just sucking up and getting on with the job beats trying to be clever, one day I might learn.

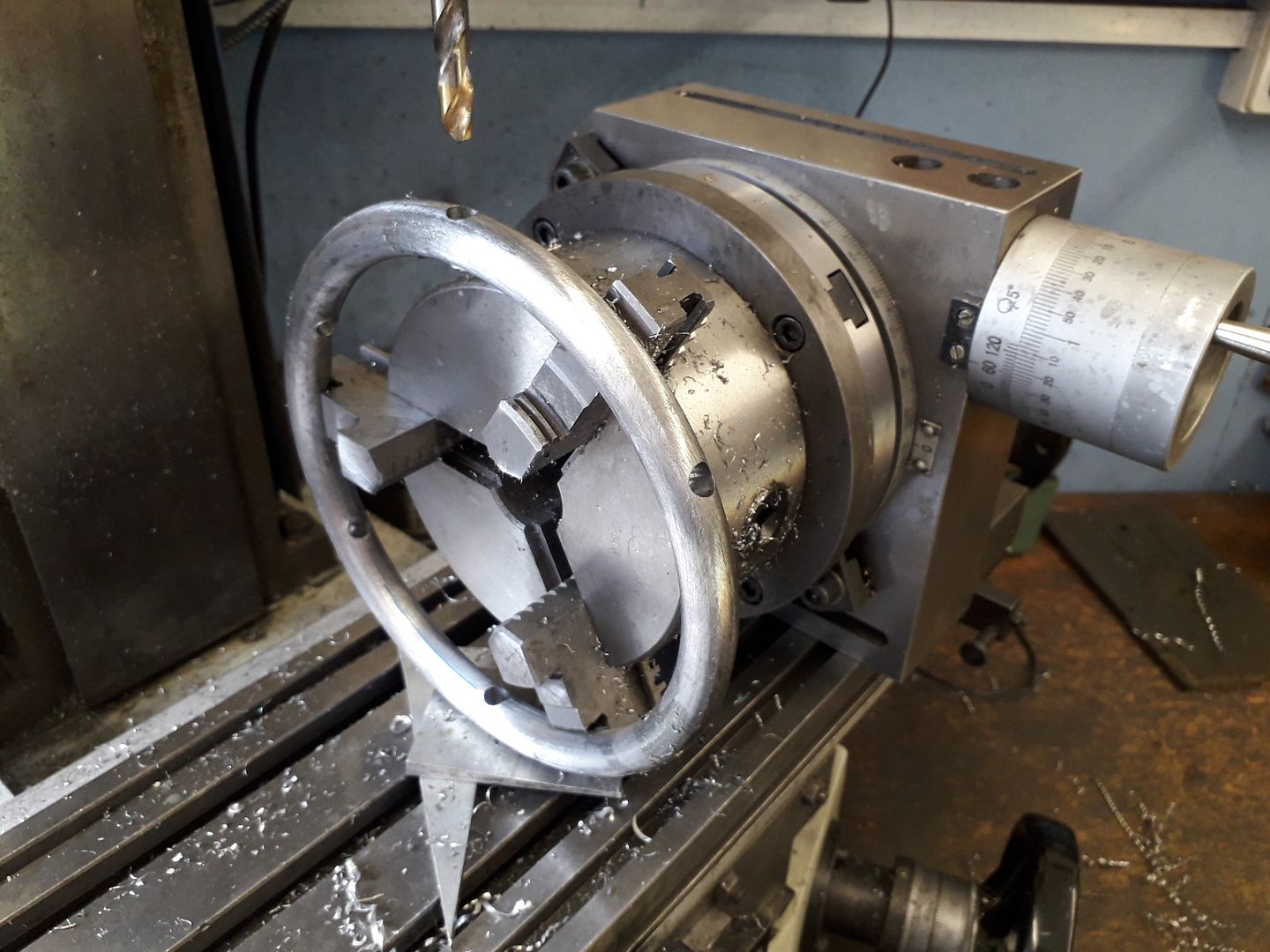

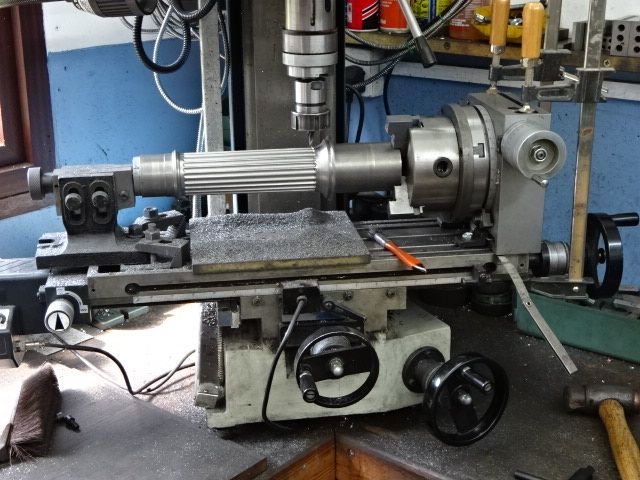

I'm inclined to think that, if you have the vertical space, a spindexer would be a better earlier investment (after the vice, DRO and table clamp kit) than a conventional horizontal – vertical rotary table. Certainly mine comes out about 6 times as often as one of the rotary tables. I have a 5C chuck for mine which is the usual work holding device despite having full sets of 5c collets in both metric and imperial.

These days ER makes more sense for the collets.

Its a pity there appears to be no kit or published design to convert a spindexer to a GHT style dividing head as such would seem well suited to ME work at an appropriate cost. The worm drive for continuous rotation being possibly of more immediate value than pure dividing head capabilities. Accessory plates for Vertex et al rotary tables would seem the sensible way to add full dividing capabilities. Perhaps Ketan at Arc could put a package together.

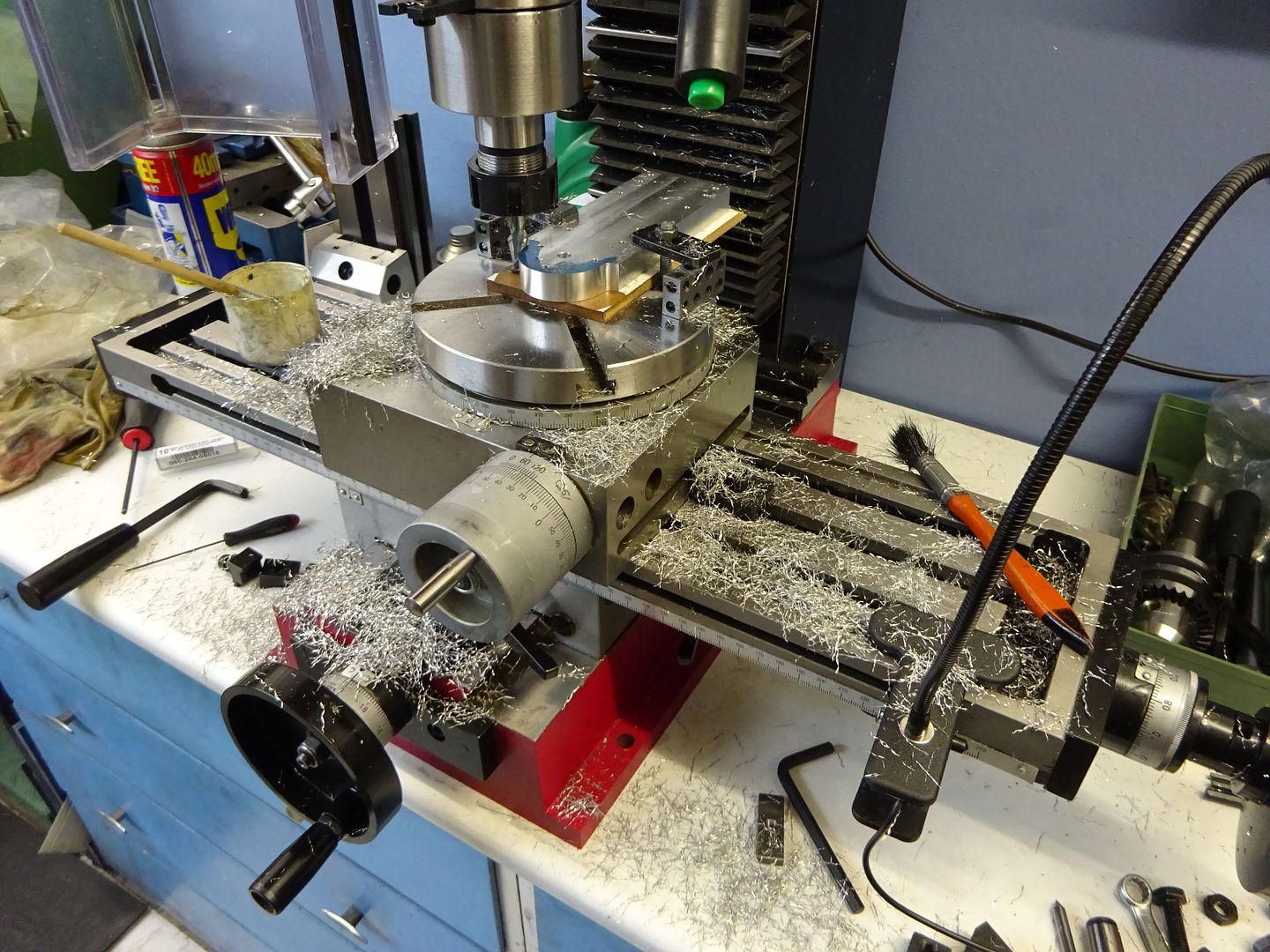

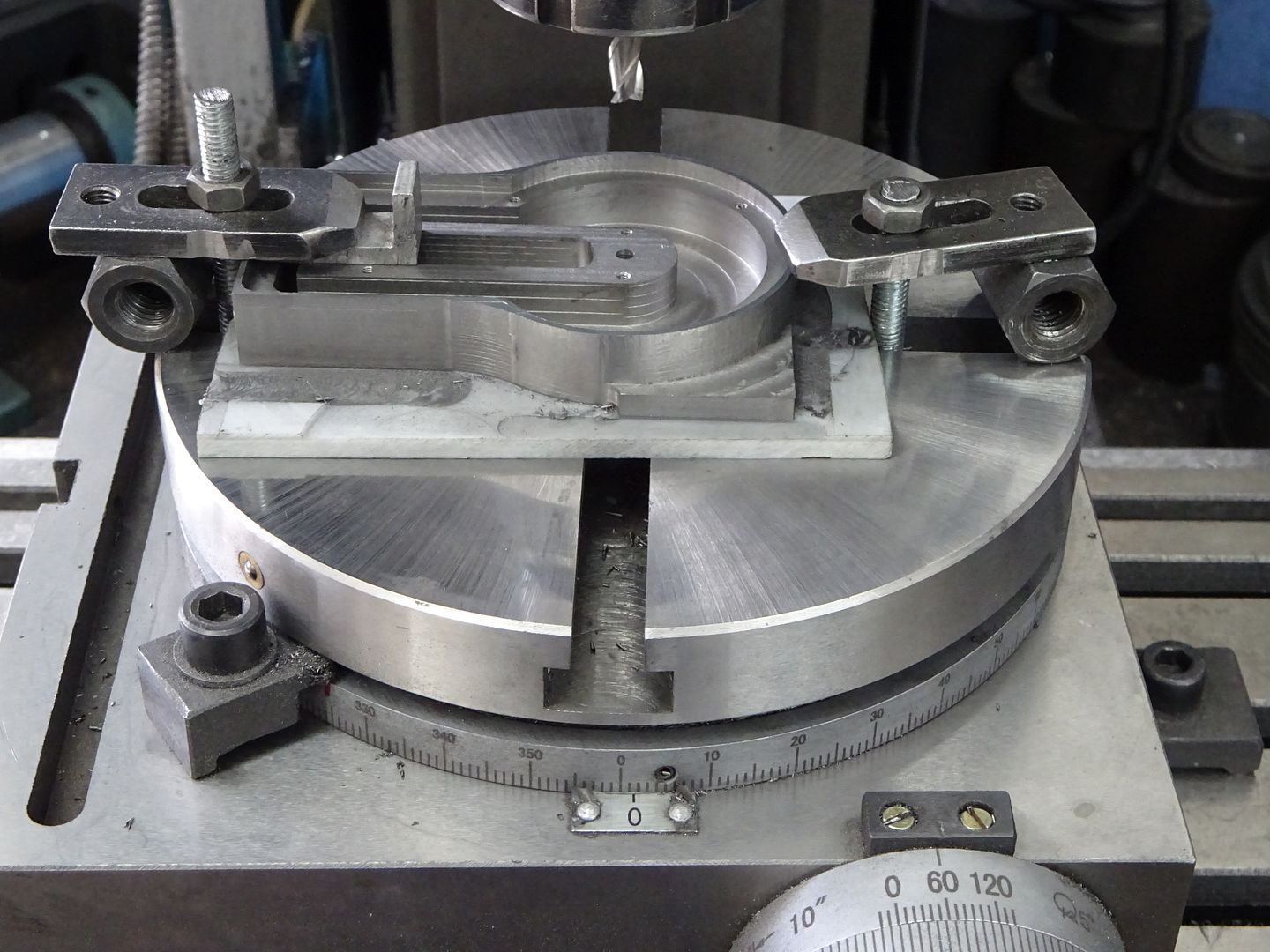

When considering the size of a rotary table its important not to underestimate the space taken up by clamps. As Jasons middle picture shows conventionla clamping usually needs more space allocated than the work. Especially with small tables. I personally think that conventional T slots with bar and step block clamping systems become somewhat inappropriate below 8" diameter due to the space needed. Can maybe used on a 6", as Jason shows, but on 4" frankly fergeddit.

A grid of tapped holes plate gives more, and more complex, clamping options than slots although the clamps are usually weaker. Which probably matters not for small work and correspondingly small cuts. Jasons first picture shows a clamp arrangment much more typical of those used with grid of holes than with Tee slots. One easily overlooked advantage of the grid of holes plate is that cantilever clamp carriers can be arranged when really short of area in one direction.

Clive

Edited By Clive Foster on 15/05/2020 13:30:46

Edited By Clive Foster on 15/05/2020 13:32:27

AdrianR.