Posted by John Reese on 05/01/2020 23:58:27:

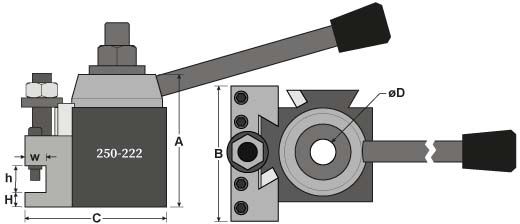

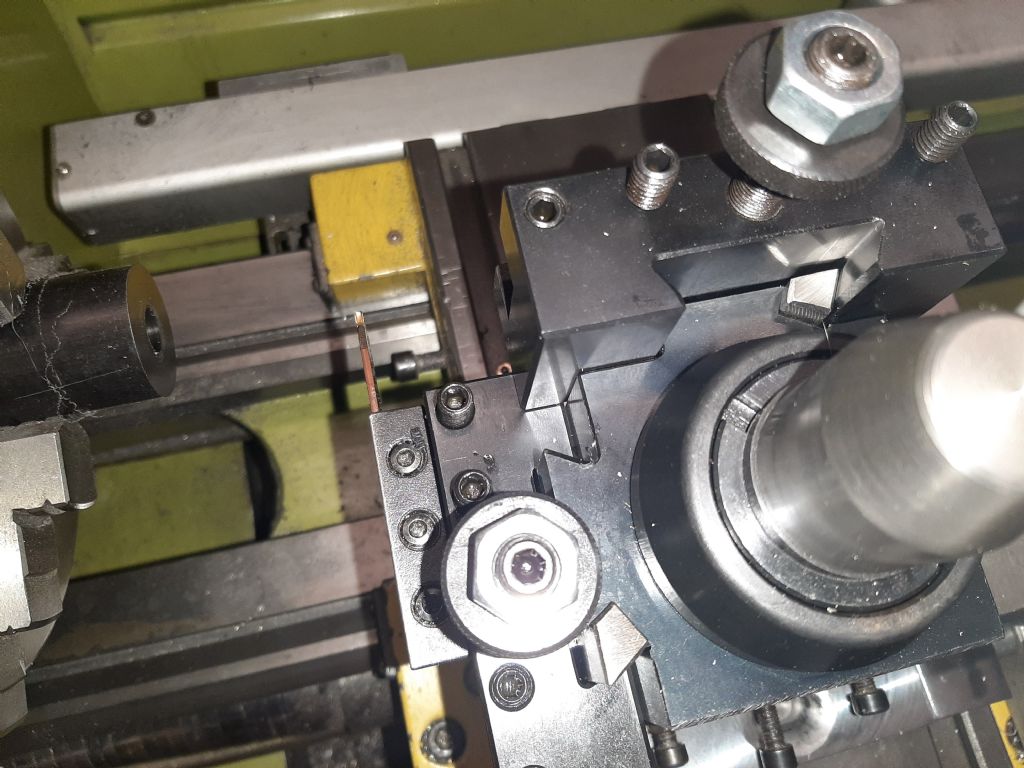

The Warco style requires the Vs be precisely spaced and parallel for repeatability. I doubt the Asian manufacturers will maintain the level of precision to allow you to buy replacement tool holders that fit properly.

Its a common misconception that Dickson style toolposts and holders need super precise spacing of the Vees to work properly. Line contact of the toolholder on either the two outer faces or the two inner faces of the post Vees is sufficient to ensure stability so small errors of spacing, in grinding machine context at least, don't matter. It is important that they be parallel and of essentially equal depth. Not intrinsically difficult given a sensible production set up. As ever design for production and inherent mutual accuracy from the, ideally simple, set-up is important if precision is to be achieved at a sensible price. The Dickson Vees are good from that aspect.

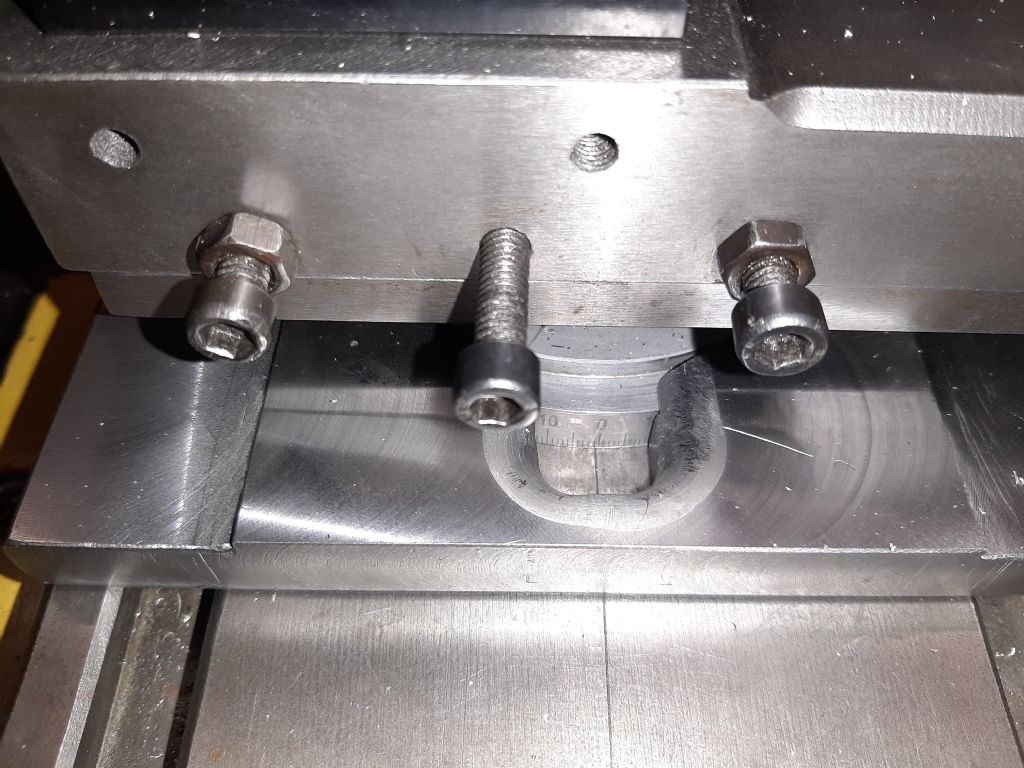

More likely to get trouble from the locking mechanism. Depending on how you count there are between 7 and 11 places where tolerance errors can build up. Functionally all that matters is that the Tee slot in the holder shall be at the right distance from the toolpost for the tongue to draw the holder hard back against the toolpost when the internal "cam" is close to pullback dead centre. The closer to centre it is the higher the pull back force but if it goes just past force will be lost.

In a practical world thats where errors are most likely to be found. If I had a poorly locking system I'd be playing about with shims temporarily glued on the locking tongue to sort out the actual errors then set about re-making the tongue assembly to functional dimensions. The unit is basically a spindle with a vertical hole through it and a flat end so not hard to make. In principle I see no reason why the tongue couldn't be simply cut off and re-fitted with a countersunk headed allen screw and spacer to get it in the right place. Practice might be a little more challenging.

Took some quick measurements off my size 2 Dickson and Rapid Tipo A posts to get some idea of industrial standards. The Dickson locking handle has 130° total movement giving about 60 thou, 1.5 mm, tongue pull back; call it 0.5 thou, 0.012 mm, per degree. The Rapid has 160° movement giving around 100 thou, 2.5 mm, pull back; call it 0.6 thou, 0.016 mm per degree. Assuming around 10° variation in spindle position at lock is acceptable that suggests something of the order of 4 thou, 0.1 mm, variation in Tee slot position can be coped with. All very handwaving (in the real world there are tangents involved!) but, if it seems like the locking spindle is turning past dead centre, it might well be worth experimenting with a 2 thou, 0.05 mm, shim under the locking tongue. Only good for trials but informative if you do consider re-making the innards. My motley collection of holders from several brands show no readily noticeable variation in locking handle position suggesting that the professional products hold total errors down around the 0.5 thou, 0.01 mm, range when mixed and matched.

Clive

Oily Rag.