Thank you for the received wisdom of the forum. More Ideas for me to ponder and experiment with.

David, I did look for taper rollers – but with a 7mm ID they seem to be unobtainium and if do find any probably out of my price range.

NDIY – One option was to create a jam nut by cutting the nut in half, but I take the point about the difficulty of holding the preload still enough – especially with a 2mm pitch. 5 degrees of shift is 0.028mm change in the preload position.

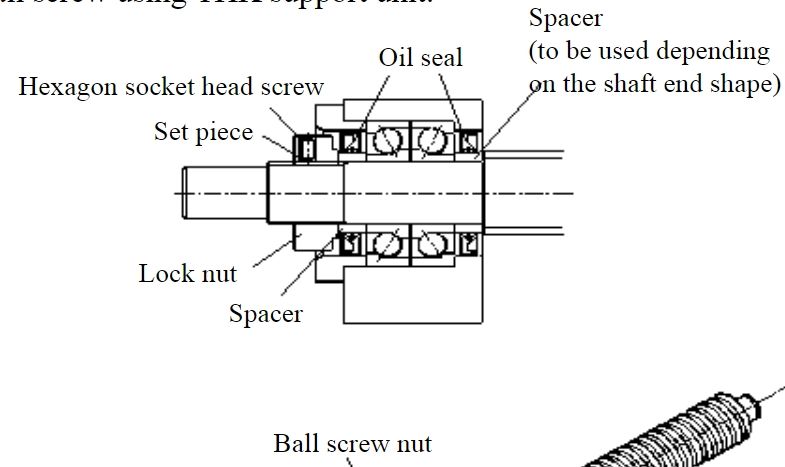

Paul, I know will have some backlash on the running nut, but I can probably live with that on the little lathe as long as the leadscrew bearings don't add to it. The idea of a fine thread on the leadscrew to make adjustment easier is interesting. Perhaps thread the dog clutch on, adjust and lock with a grubscrew. A ballscrew is serious overkill for the purpose.

Thanks to everyone for the ideas. I have a couple of nuts on order with the leadscrew, so may try the grubscrew with a brass or copper slug, DC's approach with a slit in the nut and threading the inside end of the leadscrew. Just to see which works best.

Edited By Peter Cook 6 on 21/06/2021 12:51:48

not done it yet.