LBSC’s Designs

LBSC’s Designs

Home › Forums › Locomotives › LBSC’s Designs

- This topic has 102 replies, 33 voices, and was last updated 18 March 2020 at 20:34 by

Michael Gilligan.

Michael Gilligan.

-

AuthorPosts

-

3 September 2017 at 20:01 #315067

John Lluch

Participant@johnlluch21161Hi Neil, I appreciate your comment and to be honest I sort of expected something like that. I can't fully agree with you though.

I meant the SI is a superior system in the sense that physical properties have single measurement units as opposed to the imperial system, which is more inconsistent in that respect. . For example power unit is 'watt' in the SI regardless of thermal, mechanical, electric… as opposed to 'HP' and 'btu/h'. There is no clear unit for work in the imperial system, the equivalent to 'joule' in the SI. There is a difficult distinction between force (or weight) and mass in the imperial system, which is not the case on the SI where force is 'newton' and mass is 'gram'. The SI also completely avoids conversion factors in formulas of practical use, as opposed to the imperial system that often requires them. This is among other advantages of the SI.

Fractions are of course exact while they remain fractions, but my point is that they can not be reliably represented in decimal numbers. Specially when converted to mm. Decimal numbers is what CAD/CAM and CNC will use, so when converting from inches to mm it all becomes a mess of dimensions with infinite (to be exact) decimal places. That causes trouble due to accumulation of errors and rounded display of dimensions. If you keep what is already in inches as it is, then there is no problem. CAD systems will handle fractional inches gracefully, and CNC machines will have anyway some working tolerances. This obviously works and have been for long time, and this is also my point.

I suppose I do not fully understand the problem you explain with laying out a slide valve and its eccentric, but I can imagine what you mean. I concede that if you are grown up using fractions it may have sense to apply them in some cases. But the industry has evolved to avoid them for some of the practical reasons mentioned above, and not using them is not a design constraint at all. Virtually everything is drawn in metric units nowadays. I have drawn a freelance locomotive from scratch (in mm of course) and I never felt the need to use any fractional dimension. In fact, from my background point of view, fractions are rather an inconvenience. In plans drawn in inches with fractional dimensions I have seen that sometimes decimal numbers must be specified to account for accumulation of fractional dimensions (specially in assemblies) that don't really add to a nice number. This never happens if everything was specified as decimal numbers already.

Edited By John Lluch on 03/09/2017 20:03:17

3 September 2017 at 20:20 #315068SillyOldDuffer

Moderator@sillyolddufferJohn Lluch raises a good question about metricating Imperial and English measure designs. Are there recommended ways and means of doing it?

Dave

PS Be interesting to know in 2017 how much professional design in the UK isn't metric. I'd guess commercial design in Imperial fractions is very rare, and that Imperial and Thou are only used for compatibility reasons.

3 September 2017 at 21:16 #315073John Lluch

Participant@johnlluch21161Posted by HOWARDT on 03/09/2017 19:37:07:Having followed this thread from the beginning, it appears that most of the comments are about copyright which not being a lawyer I won't comment. My thought is perhaps more important. If it is the intention to keep the creations as CAD models and drawings, what format will be used. I worked as a designer all my life, and went to CAD in 1989. With changes to the core of the CAD systems old files become unreadable unless you convert immediately after the change. Also later minor changes make for incompatibility. The only sure way is to create jpg scans or similar, even PDF may not be an option. Just a thought, but been there and got the tee shirt on reading old files!

That's indeed an important point and one which is very difficult to place a proper suggestion for. Both jpg and pdf are nowadays pretty standard file formats and ones that will hardly be broken or made incompatible with other formats in the future. However, they both are meant to hold 2D information (such as pictures or printable content) and they are not editable, so in case an error is latter found the original CAD file will always be required. Between the two I would chose pdf, provided the purpose is only to distribute static content to be printed by the end user

About CAD, I am not aware of any format that would open (in an editable form) in all software platforms. However, for the purposes of dynamic display only, there are several file types that will open in most CAD systems. This does not solve of course the problem of maintaining an editable version of the 3D plans, which will be required to keep future compatibility. I am used to SolidEdge from Siemens because that's what I learned, and that's what I would chose, but I suppose SolidWorks can be considered a better choice because I understand it is more widespread. Other CAD systems have options to import SolidWorks files, though generally in a non fully editable way.

Finally, if the possible legal issues about ownership can be solved, a good thing to do would be to open source the 3D plans files to let everybody propose improvements or correct errors by pushing updates based on experience while building the actual locomotives.

Edited By John Lluch on 03/09/2017 21:18:52

Edited By John Lluch on 03/09/2017 21:20:13

Edited By John Lluch on 03/09/2017 21:20:50

3 September 2017 at 21:25 #315076Anonymous

Posted by John Lluch on 03/09/2017 20:01:39:Decimal numbers is what CAD/CAM and CNC will use…………

The last time I looked computers used binary; conversion to/from decimal is only for the convenience of the operator.

Andrew

3 September 2017 at 22:08 #315080 Roderick JenkinsParticipant@roderickjenkins93242

Roderick JenkinsParticipant@roderickjenkins93242My view is that conversion to metric is not about the actual measurements of a fabricated item but what size stock is used. For example, LBSC may call for the valve stem to be made of 1/8" ground stainless steel rod. 3.175mm stainless rod is not the sensible option, 3mm probably is but all other components interfacing with the rod need to be adjusted accordingly. The situation with frame material is already a problem since the material specified by LBSC in Standard Wire Gauge is no longer available. I would be inclined to re-draw the designs in imperial (with SWG and number/letter drills converted to imperial decimals). A builder can then make the decisions about which dimensions to adjust to make the design work with the stock he has available.

I'm unaware of any serious industry in the UK that uses imperial measurements these days – certainly not in the defence/nuclear industry I used to work in.

Cheers,

Rod

3 September 2017 at 22:08 #315081 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattPosted by John Lluch on 03/09/2017 20:01:39:

Decimal numbers is what CAD/CAM and CNC will use, so when converting from inches to mm it all becomes a mess of dimensions with infinite (to be exact) decimal places. That causes trouble due to accumulation of errors and rounded display of dimensions.

Not strictly true, as imperial fractions are all powers of two, they are rather well suited for representation by computers. Even the worst case of converting 1/128ths to millimeters it's only seven decimal places, exact.

If only they had settled on 1"=25.6mm….

Also, I'm not defending the whole imperial system, I'd rather use SI for anything complex, and remember that CGS and MKS systems were 'metric' but almost as impenetrable as imperial for some purposes.

But inches vs millimeters? As the difference is just a multiplication by a constant, I fail to see what the fuss is about, they are equivalent. Imperial has fractions as an optional extra. Metric's optional extra is preferred sizes. I prefer fractions!

The real issue, for me, is availability of stock materials. The prophets of doom forecast the decline of imperial stock back in the 70s but 45 years on it is only a few areas (such as screws) where imperial sizes are starting to fade away. I would always build an odd design in imperial units using those units, and a new metric design in metric. I have started using metric for my new designs as that 'future proofs' them, with the exception of models of old prototypes. It seems a bit daft not to use imperial when modelling an imperial prototype at 1:12 or 1:16 as that means many of the full size dimensions come out as neat equivalents, whilst almost none will if modelling in metric.

Neil

3 September 2017 at 23:20 #315087duncan webster 1

Participant@duncanwebster1If you have to add 3/64" + 1/2" + 3/32" you'll be reaching for your calculator. I know you can do it by converting everything to 1/64" but the scope for going wrong is massive. You've got to convert to decimal to use a micrometer anyway, unless you have a mic that reads in 1/1024" and a very good capacity for mental arithmetic.

I find Neil's argument that imperial makes things easier for 1/12 scale a bit difficult, it only applies if you're prepared to work in fractions based on 12 (ie 1/12", 1/24" etc). Similarly, scaling say 5&3/8" at 1/16 gives 43/128, which isn't all that handy. My ruler doesn't have 1/12" (or 1/128" for that matter) and bar stock certainly doesn't come in such outlandish units.

I'm not going to dump all my imperial tackle, but I'm not going to buy any more. If we want to interest the younger generation we are going to have to speak their language. They are not going to learn a new system of units.

I too remember doing sums in Imperial, having to remember factors of 32.2, 384, 778, 550, 33000 etc etc did not make life any easier. It is soooo much easier in SI

Edited By duncan webster on 03/09/2017 23:21:04

3 September 2017 at 23:53 #315090John Lluch

Participant@johnlluch21161Posted by Neil Wyatt on 03/09/2017 22:08:15:Posted by John Lluch on 03/09/2017 20:01:39:

Decimal numbers is what CAD/CAM and CNC will use, so when converting from inches to mm it all becomes a mess of dimensions with infinite (to be exact) decimal places. That causes trouble due to accumulation of errors and rounded display of dimensions.

Not strictly true, as imperial fractions are all powers of two, they are rather well suited for representation by computers. Even the worst case of converting 1/128ths to millimeters it's only seven decimal places, exact.

Hi Neil,

I am not totally sure of that because I'm not too used to it, but I recall having seen fractions in LBSC plans that were divisible by 3. This creates a periodic number with an infinite number of decimals.

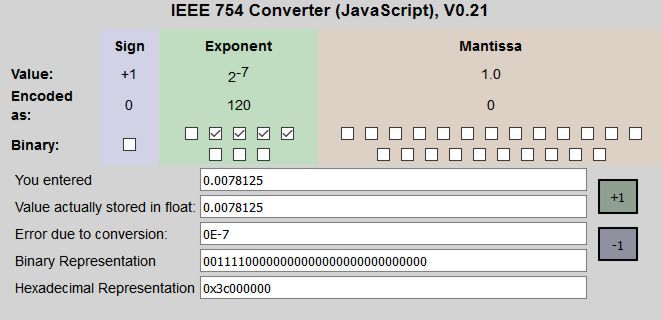

As it has been mentioned, this is further complicated because computers store numbers in binary format. Indeed, numbers in computers are represented in a convened binary notation (IEEE-754) that uses a normalised floating exponent of two (also in binary). This representation is commonly known as floating point number. The reality is that an apparently simple decimal number may require an infinite series of binary digits to be an exact representation of the same number. For example the number 0.1 in decimal notation is a periodic number in floating point binary representation, in fact, when converted back from single precision floating point representation to decimal notation, the result gives errors from the 9th decimal place (0.1 converted to IEEE-754 and back to decimal turns to be 0.100000001490116). But I think this is beyond the topic of this forums and of little interest for the discussion that is going on.

Just to clarify my points on my earlier posts, my suggestion all the time was to stick to inches and imperial units for the existing LBSC designs when redrawn in CAD. I am NOT advocating any translation to metric, but just the opposite. However, I manifested my preference for the metric system in general and for any new designs, which should not become the main topic of this thread.

4 September 2017 at 07:09 #315096 Ady1Participant@ady1

Ady1Participant@ady1If you have to add 3/64" + 1/2" + 3/32" you'll be reaching for your calculator

A computer program would do it for you

Off the top of my head I would use 256 x 25.4 = 6502.4mm exactly matches 256 inches

So 3 + 32 + 6 = 41 (64ths)

6502.4/64 = 101.6

x 41

/256

= 16.271875 mm

Hmmm. Could get boring after a few hundred times…

4 September 2017 at 07:45 #315101 Neil WyattModerator@neilwyattPosted by duncan webster on 03/09/2017 23:20:11:

Neil WyattModerator@neilwyattPosted by duncan webster on 03/09/2017 23:20:11:If you have to add 3/64" + 1/2" + 3/32" you'll be reaching for your calculator.

Took me about two seconds to get 41/64…

4 September 2017 at 07:49 #315103 JasonBModerator@jasonbPosted by Neil Wyatt on 04/09/2017 07:45:43:Posted by duncan webster on 03/09/2017 23:20:11:

JasonBModerator@jasonbPosted by Neil Wyatt on 04/09/2017 07:45:43:Posted by duncan webster on 03/09/2017 23:20:11:If you have to add 3/64" + 1/2" + 3/32" you'll be reaching for your calculator.

Took me about two seconds to get 41/64…

Well you had probably just read the 41/64ths in Ady1's post

4 September 2017 at 08:03 #315106

4 September 2017 at 08:03 #315106Marcus Bowman

Participant@marcusbowman28936Posted by John Lluch on 03/09/2017 21:16:28:Posted by HOWARDT on 03/09/2017 19:37:07:If it is the intention to keep the creations as CAD models and drawings, what format will be used. I worked as a designer all my life, and went to CAD in 1989. With changes to the core of the CAD systems old files become unreadable unless you convert immediately after the change. Also later minor changes make for incompatibility. The only sure way is to create jpg scans or similar, even PDF may not be an option. Just a thought, but been there and got the tee shirt on reading old files!

About CAD, I am not aware of any format that would open (in an editable form) in all software platforms. However, for the purposes of dynamic display only, there are several file types that will open in most CAD systems. This does not solve of course the problem of maintaining an editable version of the 3D plans, which will be required to keep future compatibility. I am used to SolidEdge from Siemens because that's what I learned, and that's what I would chose, but I suppose SolidWorks can be considered a better choice because I understand it is more widespread. Other CAD systems have options to import SolidWorks files, though generally in a non fully editable way.

Finally, if the possible legal issues about ownership can be solved, a good thing to do would be to open source the 3D plans files to let everybody propose improvements or correct errors by pushing updates based on experience while building the actual locomotives.

Interesting points, raising different issues.

Firstly. although I like the idea of open source plans available in an editable format, the CAD platform would have to be open source, to allow anyone to edit or alter the plans. There are several possibilities, but there is a somewhat larger question. The nature of open source suggests that a user could make changes and re-post the plans. That might be useful for allowing the correction of universally accepted errors or making necessary modifications. But that leads to two questions: who is to say those errors and/or modifications are necessary (because the plans would then deviate from the original); and who then controls availability of the new open source plans?

One solution is to use a platform such as GIT, where changes are tracked, and it is clear which versions are which, and, especially, which is the current version.

Controlling the addition of modifications and 'enhancements' becomes important as plans are changed and morph into something else, over time. Take 'Pansy' for example. Doug Hewson's version is more accurate and up-to-date, incorporating much more modern approaches, so if I was to make a Pansy, I would choose Doug's drawings. But would it then be fair to call that LBSC's PANSY? It's not a straightforward question. I would not want to use any of the LBSC boilers, because they really need to be brought up to date to comply with current legislation and safety requirements. But does changing the boiler make those designs non-LBSC? We need some person or group to control this aspect.

I might draw the distinction between the developmental course of Mach3 and LinuxCNC, for example. Mach3 was originally updated and amended by its creator. When it was sold on, modifications and bug corrections stopped, as the new owners focussed on Mach4 development. They control development, so that was their choice.

LinuxCNC, on the other hand, is open source, and undergoes active development, with new versions available from a central repository. The development is driven by user suggestion and by the willingness of users to contribute to that development. Older versions remain available.

A mechanism of some sort is required to manage any changes. It could either be the original draughtsman, or a user-driven group. What would not be good would be the model where development was frozen once the initial drawings had been released.

As to the format of the plans; this could either be an agreed open source CAD package, or simply the DXF files. The difference is that having the CAD package available to everyone would allow anyone to edit the plans and perhaps incorporate their own mods, for their person use. The DXF files would be the most useful for the person who simply wanted to take and use the plans. DXF may allow some modifications within some packages, but would certainly allow the CAM stage to take place, to prepare G code files for manufacture by CNC.

PDF files would allow non-CNC manufacture, just like existing paper plans. The benefit of PDF files is that printing could take place at any size or scale. Larger format plans can be printed by may local print/copy shops.

JPEG files are not quite as useful, if the print size is to be made larger, as definition suffers when the file is enlarged beyond the native size. PDF, on the other hand, scales well.

Marcus

4 September 2017 at 08:08 #315108 Neil WyattModerator@neilwyattPosted by John Lluch on 03/09/2017 23:53:23:Posted by Neil Wyatt on 03/09/2017 22:08:15:

Neil WyattModerator@neilwyattPosted by John Lluch on 03/09/2017 23:53:23:Posted by Neil Wyatt on 03/09/2017 22:08:15:Posted by John Lluch on 03/09/2017 20:01:39:

Decimal numbers is what CAD/CAM and CNC will use, so when converting from inches to mm it all becomes a mess of dimensions with infinite (to be exact) decimal places. That causes trouble due to accumulation of errors and rounded display of dimensions.

Not strictly true, as imperial fractions are all powers of two, they are rather well suited for representation by computers. Even the worst case of converting 1/128ths to millimeters it's only seven decimal places, exact.

Hi Neil,

I am not totally sure of that because I'm not too used to it, but I recall having seen fractions in LBSC plans that were divisible by 3. This creates a periodic number with an infinite number of decimals.

I hope my comments are taken in the spirit of light hearted musing on the subject, not an argument for arguments sake…

It's the denominator that matters, you won't have seen an LBSC fraction whose denominator wasn't a power of two. So 1/128 (for example)

Having written a BASIC interpreter I know about floating point representation. You've actually handed me a wonderful proof that imperial fractions are better than metric decimals…

As you say figure such as 0.1 can't be stored precisely on a computer using usual floating point formats, but let's try a fraction, such as 1/128, the smallest you are likely to find (I have to input the fraction as the equivalent decimal):

Oh look! The error is… nothing!

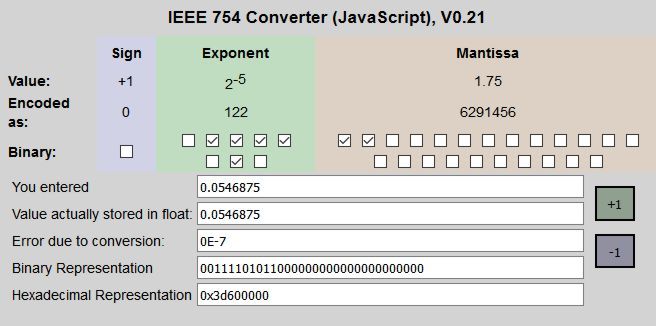

Forget multiples of three, let's use a prime number as the numerator, how about 7/128:

Wow! Perfect representation again. Clearly Imperial fractions are completely superior.

Duncan makes fair comment that, at 1:12, for example some dimensions become inconvenient. A 1" dimension becomes 1/12" which is rather awkwardly between 1/16" and 3/32" stock sizes.

That's why I said many full size dimensions some out as convenient sizes not all.

Due to a quirk of fate 1mm ~= 1/24" so fortunately 2mm is close enough to use without anyone noticing!

This makes 1:12 a very convenient scale to work to if you want to use as many readily available stock sizes as possible.

Metric buffs can work to 1:10 which is fine for most things but raises problems on popular rail track gauges.

Neil

4 September 2017 at 08:09 #315109 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattFor the sceptical:

4 September 2017 at 08:31 #315115 JasonBModerator@jasonbPosted by Neil Wyatt on 04/09/2017 08:08:31:but let's try a fraction, such as 1/128, the smallest you are likely to find (I have to input the fraction as the equivalent decimal):

JasonBModerator@jasonbPosted by Neil Wyatt on 04/09/2017 08:08:31:but let's try a fraction, such as 1/128, the smallest you are likely to find (I have to input the fraction as the equivalent decimal):Ah but what about a part dimensioned as "full" or "shy" you can't easily express that as a fraction

Easy enough to do in decimals by increasing or decrasing by say 0.01mm or 0.0005"

4 September 2017 at 08:51 #315119John Lluch

Participant@johnlluch21161Posted by Neil Wyatt on 04/09/2017 08:09:31:For the sceptical:

Hi Neil, You are an interesting man lol. Actually, while I was posting my 0.1 decimal to floating point binary conversion example, I wondered if you (or somebody) would refute that by showing fractions that are powers of two. I honestly didn't think this would be the case on a model engineering forums. But I'm absolutely delighted about your reply!. Having written a BASIC interpreter puts you in a strong position for that. My background is computer software development, and I too have written a couple of interpreters of common (old) computer languages, and a compiler for a specialised computer language aimed at the knitting industry. I am also the main developer of the HMI Draw and HMI View apps in the App Store, which also contain a real time pseudo-compiler to RPN for fast execution of Ruby expressions.

So yes, you are right. Indeed, fractions commonly used in imperial dimensions have a better representation in computers.

4 September 2017 at 09:00 #315121IanT

Participant@iantAn interesting point Neil – but since we've drifted well away from LBSC – onto the use of floating point with it's various issues – another quick aside.

I play with embedded devices occasionally and use a Forth factoring technique to simply avoid the use of floats completely. Simply put – decide the very smallest value to be worked to – say 1 thou – and that becomes your base integer value. An inch is then represented 'internally' as 1000 – so all arithmetic is integer based – conversion to/from the base factor occurring only on input and output.

This also seems to be my own 'embedded' computers way of working too – generally thous seem easier for me to work with if anything is less than an inch (no built-in FPU I guess)

Regards,

IanT

4 September 2017 at 09:53 #315134John Lluch

Participant@johnlluch21161Marcus. I would expect that as younger generations enter the hobby, the development of open source communities supporting and updating model engineering plans in CAD format will eventually become a reality. You are making very valid points on this subject.

IanT. I also want to add that Integer numbers up to a certain figure are EXACTLY represented in floating point formats. Also floating point arithmetic of integer numbers is EXACT. I have no doubt that CAD software uses floating point numbers to store internal dimensions, but I sometimes suspect that the actual stored values are scaled up to a particular factor to prevent accumulation errors. I do not know about other CAD packages, but I never, and I mean NEVER, have seen or suffered an accumulation error on SolidEdge. It behaves for example as if 1 was internally stored and computed as 10000, or 0.1 as 1000 and so on. So unless you get to specify a really small number or a dimension with a ridiculous amount of decimal places, the chances of accumulation errors are nil. This, or the software uses a really clever approach at rounding floating point arithmetic errors.

Edited By John Lluch on 04/09/2017 10:17:25

4 September 2017 at 11:05 #315146 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133John,

The fractions debate has, I think, been concluded … but let me just mention one practical instance, from personal experience.

The interface dimensions for the 5" x 4" 'Graflex' sheet film holder [which became a de-facto standard for the camera industry] were very obviously designed in 1/128ths.

Years ago, Polaroid very kindly provided me with a copy of their drawings for the 545 film holder **LINK** http://camerapedia.wikia.com/wiki/Polaroid_545

and when working through these, it became immediately apparent that the clumsy-looking decimal dimensions were in fact 'rounded' conversions from exact fractions.

I don't know how common the practice of designning in 'woodwork' units was; but I think it was fairly widespread in the USA, in the late 19th & early 20th centuries.

MichaelG.

4 September 2017 at 12:23 #315154John Lluch

Participant@johnlluch21161I miss a 'like' button in this forums.

4 September 2017 at 13:41 #315159SillyOldDuffer

Moderator@sillyolddufferPosted by Michael Gilligan on 04/09/2017 11:05:22:

…

I don't know how common the practice of designning in 'woodwork' units was; but I think it was fairly widespread in the USA, in the late 19th & early 20th centuries.

MichaelG.

I too am conscious that we risk deviating too far from Dean's original question, but it may be helpful to understand the mindset of early British designers. Before about 1900 decimals were not universally taught in British Schools and I expect the same was true in the US. Instead, pupils focussed on fractional representations because back then fractions were the basis of most practical systems of measurement: an ounce is 1/16 of an avoirdupois pound; a shilling is 1/20 of a pound sterling; a foot is 1/3 of a yard; an hour is 1/24 of a day etc. etc. In that context, fractions can simplify mental arithmetic.

Despite the utility of fractional systems in simple cases, they bite in complex situations. In contrast the decimal system is smoothly suited to the more difficult sums required in finance, science, mathematics, statistics and advanced engineering. In these fields it is understood that a number can be expressed to any desired accuracy simply by calculating more decimal places. Decimal worked very well back in the day with Slide Rules and Log Tables etc, and they remain solid in modern times on computers. Fractions are still taught, and are still useful, but the demise of old measure has undermined their previous importance. Today most of us work in decimal.

However, in the 19th and early 20th century, most practical Brits doing design would have had a natural bias towards fractions. It made design easier, though probably not optimal. In a 19th century workshop, fractions would have been well understood, decimals less so. But technology was being driven forward by numerate science, maths and engineering, in which most calculation was inexorably decimal. Electrical Engineering and Aerospace do not feature fractions. Even so I think decimal took about a century to replace fractional methods in British Design. I have Engineering Drawing textbooks that seem to bear this out. Parkinson (1933) is almost entirely fractional with decimals only appearing in the gear section. Abbott (1949), is mainly fractional but it's not unusual to find examples of mixed fractional and decimal dimensions in the same drawing, and several examples are entirely decimal. In my 1972 textbook, fractions have gone completely – Mott is decimal throughout.

There's a change of approach in the 1972 book as well. The drawing examples in the earlier books are of Steam Age objects like Flywheels, Con-rods, Couplings and Wall Brackets. Mott has none of those: his examples are generalised with ideas that can be applied to any engineering object. For example, in Mott, the design of a lathe half-centre is about developing curves, not about drawing a centre of a particular size. Mott is about design effectiveness rather than keeping the arithmetic simple. Presumably the shift was partly made possible by the appearance of calculators and other mechanical aids. However it's done, design is hard work!

It may take a long time but my feeling is that LBSC's designs are heading for oblivion in their original form. They are already difficult to implement in most of the world and signs of stress are apparent in the UK. Some items (like plates rolled to a gauge thickness) are no longer available and others are unpleasantly costly.

My feeling is that the best way forward would be for Dean to capture the designs with their original dimensions. Once that's done, a second stage would be to pragmatically convert dimensions so that the engines can be easily built using metric materials. Metrication could be done by someone else. Conversion would also flush out LBSC's mistakes and, if necessary, provide an opportunity to to modernise the design. I suggest LBSC's designs are a product of their time. If LBSC were 25 today, I think he'd work in metric. After all his objective was to make live steam practical for the average builder, not to make life hard by insisting on obsolete ways and means.

Dave

4 September 2017 at 14:16 #315162 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Excellent post, Dave

… Very well-reasoned.

MichaelG.

4 September 2017 at 14:35 #315164Bob Youldon

Participant@bobyouldon45599Hi all,

Going back to the original posting regarding the LBSC designs, it must be remembered most date from the early twenties through to the mid sixties and the imperial measurement was in full swing; not one of his designs was intended to be produced by todays CAD, CNC, rapid prototyping etc, each were intended to be a hand built job using the limited facilities that were available then and all fitting was by hand by the builder, it doesn't matter a jot if it's measured in whatever unit the builder choses. I would suggest some of the correspondents read his Maisie instructions, or come to that Martin Evan's Springbok, both designs have been built in their hundreds, probably more examples than their full size counterparts! Steam locomotives are not complicated.

Take a look at the drawings for Stephenson's Rocket, 1/64"s and 1/128"s abound, no metric there then! and that's where it all started.

As I approach my mid seventies I will and can easily work in either imperial or metric, I have to; it doesn't faz me but don't decry one format as one being better that the other.

When it comes to the actual process of constructing your locomotive, I'd like to see the first all CNC built boiler!

Regards,

Bob

4 September 2017 at 15:40 #315169 Neil WyattModerator@neilwyattPosted by IanT on 04/09/2017 09:00:45:

Neil WyattModerator@neilwyattPosted by IanT on 04/09/2017 09:00:45:An interesting point Neil – but since we've drifted well away from LBSC – onto the use of floating point with it's various issues – another quick aside.

I play with embedded devices occasionally and use a Forth factoring technique to simply avoid the use of floats completely. Simply put – decide the very smallest value to be worked to – say 1 thou – and that becomes your base integer value. An inch is then represented 'internally' as 1000 – so all arithmetic is integer based – conversion to/from the base factor occurring only on input and output.

It is great fun devising ways to generate 'adequate' precision numbers using an 8 bit microcontroller. I used one to generate a table of sines*256, the calculation looked up the sine of an angle (in 0.5 degree steps) then multiplied the hypotenuse length by it, then dropped the low bit to give the length of the adjacent side. The table used one byte per step, but had to trap values of 87 degrees or more as they needed to be 0x100, in which case they simply returned the same as the input. Fine for graphics on a 64×128 screen!

Neil

4 September 2017 at 19:44 #315216duncan webster 1

Participant@duncanwebster1It is great fun devising ways to generate 'adequate' precision numbers using an 8 bit microcontroller

Neil

The expression 'should get out more' springs to mind. I've just spent at least an hour sorting out why some code gave silly unpredictable results. Turned out to be trying to handle numbers too large to be integers. I've had this trouble before, so it didn't take the days it took last time, but I shoud have spotted it straight away

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Locomotives › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Smart & Brown Model L lathe help required

Started by:

AJAX in: Manual machine tools

- 1

- 3

-

23 August 2025 at 21:14

AJAX

-

Blackgates 3 Way Toolpost Casting

Started by:

John McCulla in: Materials

- 11

- 16

-

23 August 2025 at 21:08

Pete

-

THE MAUDSLAY TABELE ENGINE

Started by:

sivtek1 in: Introduce Yourself – New members start here!

- 1

- 1

-

23 August 2025 at 21:01

sivtek1

-

A4 stainless

Started by:

David Ambrose in: Materials

- 11

- 15

-

23 August 2025 at 20:05

Martin Kyte

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 11

- 13

-

23 August 2025 at 20:04

Marcus Bowman

-

QCTP for chester lathe

Started by:

Chris12 in: Beginners questions

- 11

- 25

-

23 August 2025 at 17:36

dk0

-

This weeks oddity!

Started by:

Martin King 2 in: Help and Assistance! (Offered or Wanted)

- 4

- 5

-

23 August 2025 at 17:29

Martin King 2

-

Asong power feed?

Started by:

Hollowpoint in: General Questions

- 5

- 6

-

23 August 2025 at 16:55

Stuart Smith 5

-

New member, progress no.1 rest

Started by:

flyingsailor in: Introduce Yourself – New members start here!

- 5

- 7

-

23 August 2025 at 16:11

flyingsailor

-

My week this week! My workshop videos

1

2

…

11

12

Started by:

Phil Whitley in: The Tea Room

- 16

- 297

-

23 August 2025 at 16:05

Phil Whitley

-

Material advice

Started by:

tobyonekenobi in: Materials

- 9

- 18

-

23 August 2025 at 11:19

Martin Connelly

Martin Connelly

-

Yet another scam

Started by:

Dell

in: The Tea Room

Dell

in: The Tea Room

- 9

- 13

-

23 August 2025 at 11:08

Howard Lewis

-

Taylor Hobson cutter grinder modificaton

1

2

Started by:

David George 1

in: Workshop Tools and Tooling

David George 1

in: Workshop Tools and Tooling

- 9

- 39

-

23 August 2025 at 08:43

Andrew Crow

-

Museum donation

Started by:

Stephen Wessel 1 in: Introduce Yourself – New members start here!

- 2

- 2

-

22 August 2025 at 20:36

Bazyle

Bazyle

-

Casting – off center hole correction

Started by:

colin hamilton in: Workshop Techniques

- 9

- 10

-

22 August 2025 at 17:38

colin hamilton

-

Granville lathe leadscrew change wheel

Started by:

JACK SIDEBOTHAM in: Help and Assistance! (Offered or Wanted)

- 10

- 17

-

22 August 2025 at 17:07

Howard Lewis

-

wood working

Started by:

Danni Burns in: Beginners questions

- 9

- 12

-

22 August 2025 at 15:55

Danni Burns

-

3″ Castings – Help/Advice needed

Started by:

Andy Porter 1 in: Traction engines

- 4

- 6

-

22 August 2025 at 13:15

JasonB

JasonB

-

AI ads

Started by:

Ian Parkin in: The Tea Room

- 5

- 5

-

22 August 2025 at 13:00

jimmy b

jimmy b

-

1″ Minnie Traction Engine

Started by:

milburyring@btinternet.com in: Traction engines

- 3

- 8

-

22 August 2025 at 08:53

milburyring@btinternet.com

-

Solar panel

Started by:

duncan webster 1 in: Electronics in the Workshop

- 8

- 13

-

22 August 2025 at 07:19

Michael Gilligan

Michael Gilligan

-

The stand alone weight for tower clock

1

2

Started by:

dk0 in: Clocks and Scientific Instruments

- 12

- 36

-

21 August 2025 at 23:59

Clive Steer

-

Install & commission of a Chester Cub 630 (Warco GH750)

1

2

3

Started by:

Calum in: Manual machine tools

- 22

- 74

-

21 August 2025 at 21:52

noel shelley

-

Softening epoxy

Started by:

John Haine in: General Questions

- 17

- 25

-

21 August 2025 at 18:57

Martin Dilly 2

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 35

- 226

-

21 August 2025 at 17:38

Dalboy

-

Smart & Brown Model L lathe help required

-