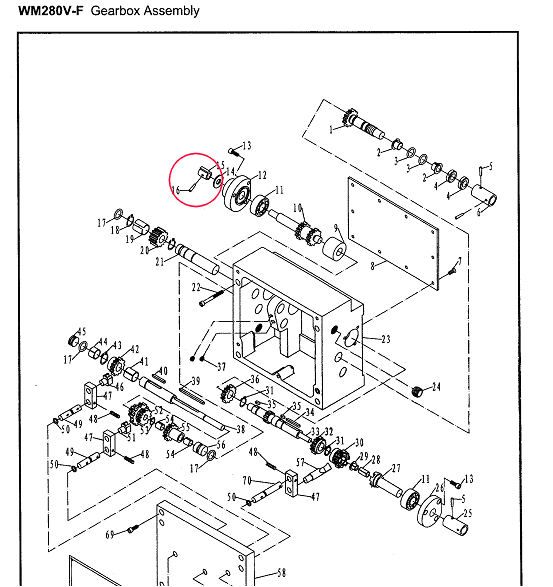

I had a go at taking it apart (found my printed manual that came with the machine), the carriage and the apron have locating pins: I was hoping that I could separate the carriage from the apron, then remove the front of the bed, slide the apron to the cut out and be able to remove the pinion without having to actually remove the apron, however I think the locating pins are possibly stopping it. I might be able to make a jig to remove the locating pins as they're tapped, but I think the gear for the cross slide feed sticks out into the carriage.

I thought about disassembling the carriage, but some of the nuts are pretty inaccessible, so it looks like I need to remove the apron.

The worm for the feed is in a bracket held on by 2 screws underneath, but removing the screws didn't enable me to slide the worm away from the apron.

I don't have much clearance on the rhs of the lathe, but I do have the engine hoist I used to get the lathe into position, so I could move the whole lathe: I've been thinking about sliding out the leadscrew to remove those covers as the seriously limit the carriage travel and I clearly should've done it earlier! I think with the leadscrew out of the way, I can possibly get the apron off.

In any case, I'll need to ring Warco for a spare part, so they probably know how to take it apart, I'm sure I'm not the first to have leadscrew cover related damage.

Thanks, Mat

Bazyle.

Bazyle.