I've used a similar method to that suggested by John McNamara, albeit not with disks, and can confirm it works well.

For disks I'd spend bit more time marking out tho' by doing 4 hexagons about 15° apart. Hexagons are easy to do as being the chord equal to the radius of the circle. So you just draw a circle and step round it then join the marks with a ruled line. Just remember its the inscribed circle that needs to be your specified diameter so the radius of the circle you draw needs to be larger than that of the disk **LINK** is a handy calculator. 4 hexagons gives you 24 points to knock off so very little left to clean up afterwards.

Flap disk is faster than file for clean up if you have a steady hand. Vertical bandfacer / linisher is great if table is large enough to support the disk. Leather gloves, hold tight and only use light cuts.

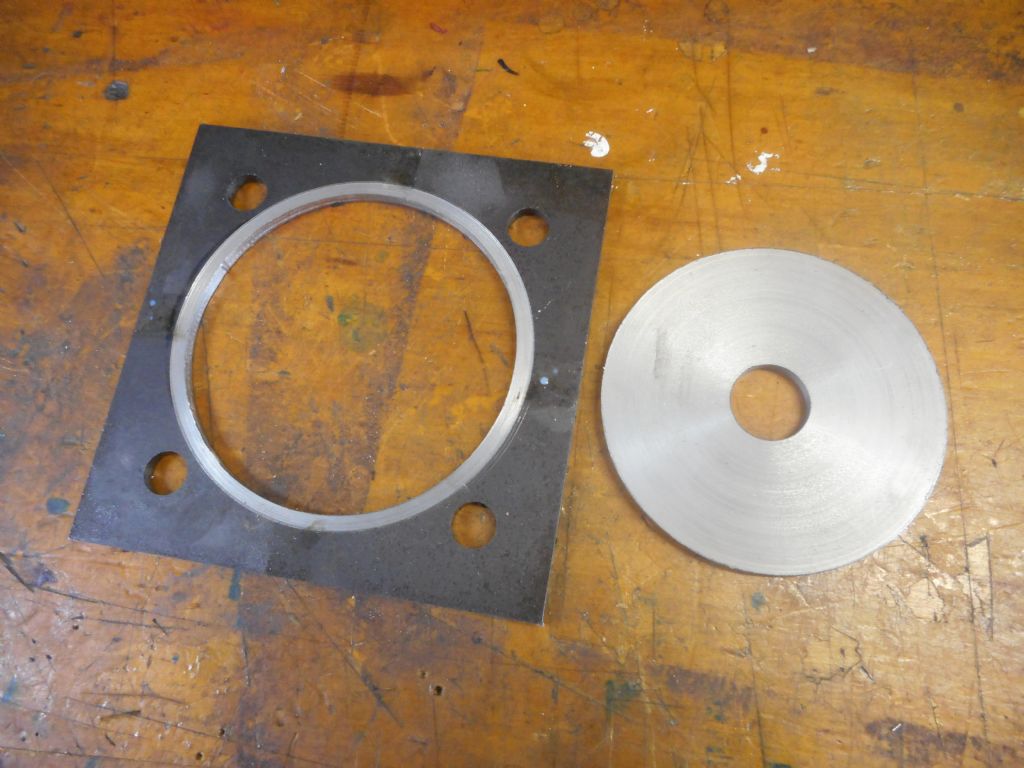

Used a Chester Lux style vertical mill to produce a couple of decently accurate 3/8" thick disks in pre Bridgeport days. Vertex 8" rotary table with "improved wood" sacrificial table. Perm one from good MFD, high density chipboard or chipboard underfloor for the sacrificial table. Have used all for such duties at some time, don't recall what I actually used for that job. Made a cavity to locate the parent piece central. Probably just screwed a thin piece of ply on top and trimmed a hole to right shape for the blanks with a router cutter on t'mill.

No access to rotary table slots for clamps to hold the material down so wood screws and washers rammed in with the power screwdriver had to do. Using a suitably large drill, selected so one turn of the handle left a small web between holes, I quickly mashed out most of the material. Similar but uneven webs being of no consequence. A slot drill of, probably, around 1/2 to 2/3 rds drill diameter (used what I had), made the accurate to size cut. Went round 2 or 3 times to get an appropriate depth of cut without excessive load on the stock. For the last cut I added more wood screws and washers to teach the inner piece manners. No longer recall the exact technique but I imagine I made the releasing cut in incomplete quadrants leaving 4 webs at 90° intervals then added more screws as close as possible to each web so the piece didn't escape on break-away.

Got good disks and didn't break a cutter so I guess that was result. In practice probably less of a faff than it seems from the written description. As is so often the case I find taking time and trouble to sort out a right first time with no fettling method is faster overall than diving in with fast rough first cut then spending ages cleaning up to size. YMMD.

Clive.

Edited By Clive Foster on 24/01/2018 13:35:38

JohnF.