Posted by Ajohnw on 10/07/2016 18:13:32:

This is likely to happen because a given pitch of knurling wheel will only produce the correct finish on certain diameters of work that will go in steps so that they divide exactly into the circumference of the work.

John

–

This is one of those urban legends that get repeated over and over again.

Knurling is a displacement operation and as such is very flexible as regards diameters.

Lets look at the logic behind the operation.

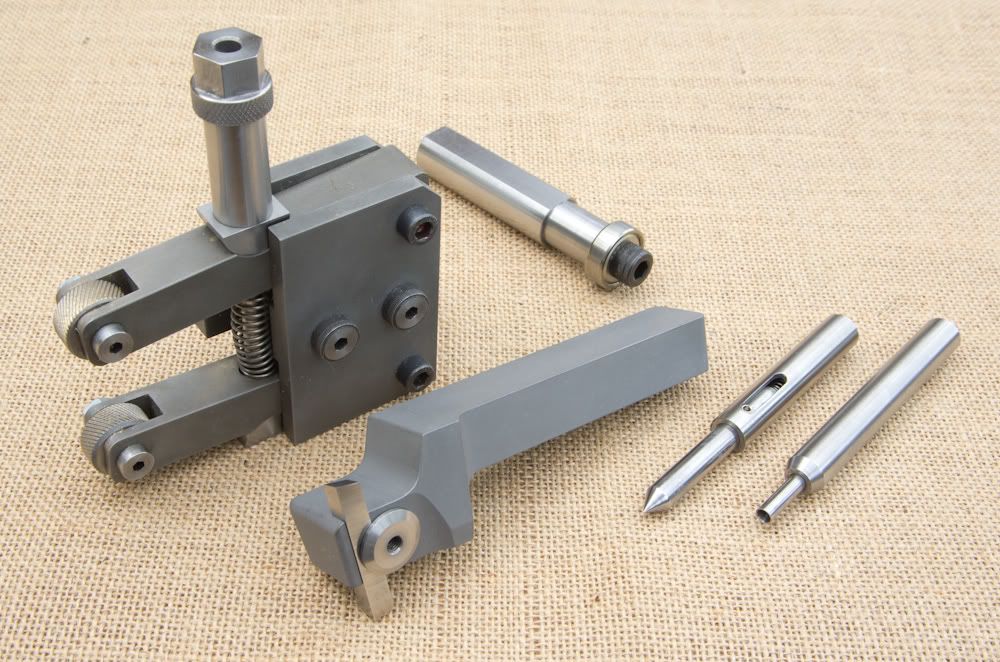

One part of knurling is written in stone and that is the wheel.

It's steel, it's hardened and it has a given pitch so everything is based round that.

So take a 1" wheel with 40 teeth as an example so the pitch is Pi divided by 40.

So 3.1416 /40 =0.0785" and will roughly have a depth of half that so say 39 thou.

So a bar 2" in diameter should finish up with 80 teeth according the the legend but thats the OD.

When it's finished to tips of the knurl wheel will be at root diameter which will be 2" – twice the depth so 0.0785 which gives us a root diameter of 1.9215 which if you multiply by Pi and divide the 0.0785 into it gives you 76.899 teeth. That's a difference of 3 teeth and we are supposed to be working accurately ??

So do you calculate on OD, root diameter or PCD because after all it's a crude gear.

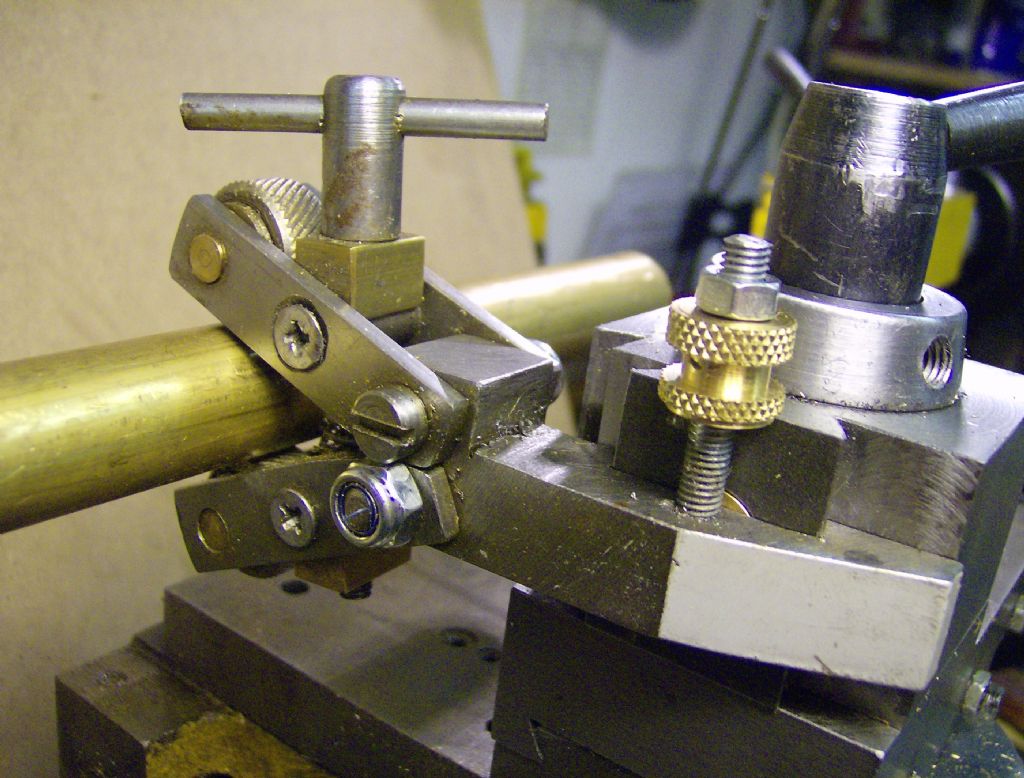

This is very easily proven.

Take a bar and take a clean up skim off it then proceed to machine a series of random steps on it. In this case they vary from base diameter to – 25 thou smaller.

Then knurl it.

You can still see the felt tip marks on it but all these diameters are good, no double knurls because the metal deforms to suit.

Mick B1.