I have ordinary bump knurls, a Brauer hand squeezed 3 wheel "nutcracker", and a Marclo professional clamp type knurling tools. Sometimes tempted to make a DIY cut knurl tool too just to see how well they work.

Rule 1 seems too be use good quality sharp knurls. The knurls do wear, especially if you show them obdurate material. Best to assume the ones on a used "bargain" are shot and that the ones included with an economy device aren't up to scratch. Dunno what were in the Marclo when I got it but a bit of stainless steel put a nice flat on one. Knurling stainless can be iffy due to work hardening but I'm pretty sure the wheels weren't OEM quality. Got replacements from Zoro which seem good, acceptable price and quick delivery.

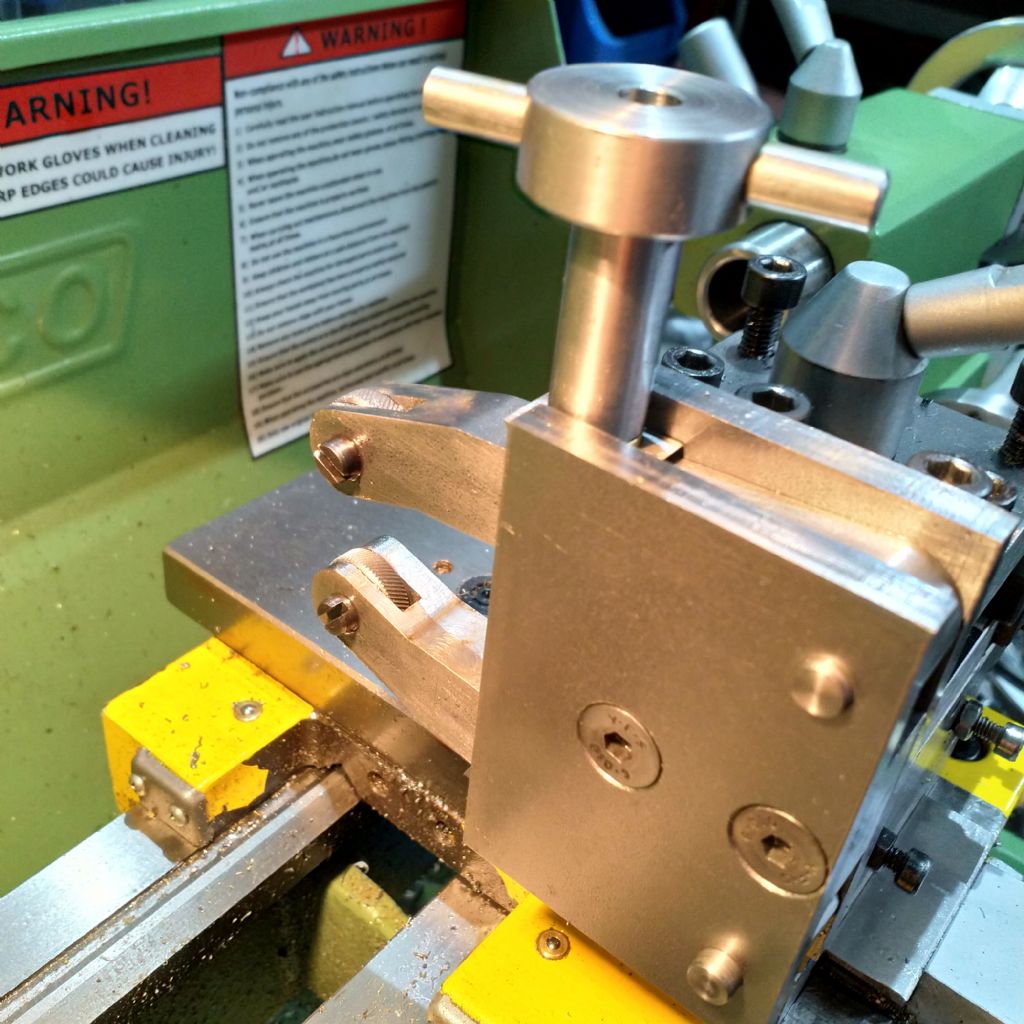

The Marlco has a hand lever to apply knurling pressure after the basic knurls just kissing the work setting has been made using the screw. Makes the whole process much more controllable as compared to relying on screw feed. Whether via cross slide for bump tool or via the adjuster of the basic clamp type. The nutcracker looks rather lightly built and a bit cheap but works unreasonably well on the more ordinary range of materials. It will do silver steel if you insist but thats being unkind. I'm convinced that the control and feel from hand squeezing or a hand lever makes the difference.

Much internet talk about getting the work size right so the knurls fit round equispaced, gear tooth style. Waste of effort in my view. Unless the job is small and the knurls coarse the difference between dead right diameter and worst possible case is small, a few thou usually. In practice knurling is a combination of cutting and displacement so things soon shave to fit if displacement alone isn't enough. Hence the desirability of coolant to wash away the thin shavings.

If you need the OD dead to size perhaps calculating the start diameter is desirable but I just have at it. Even coarse knurls on a nominal 3/8" diameter shaft went just fine with the nutcracker.

The Marclo is very heftily built. Much stouter than the common DIY clamp designs but can still deflect a little if you get careless. I'm inclined to believe that stoutness is important for easy, reliable results and that the usual DIY proportions are inadequate for anything much over an inch diameter. Being a bit on the light side doesn't stop the DIY breed from working but it just makes it harder as more care its needed.

Clive

Howard Lewis.