Clive,

Miller DID have two pivot points on all but one of his four suggested layouts, it isn't obvious at a glance, but do look again.

Imagine rotating the drawing until the line in the patent drawing is vertical, I don't think the angle affects the mechanics at all.

I think all the illustrated layouts (including the second page) allow equal and opposite forces on the knurls, and just like modern ones the skill is in applying the right degree of force and moving the toolpost back and forth to get the knurls more or less diametrically opposite for best results.

Miller's second page of drawings shows a block being placed between the arms to lock them, and allow them to be used as a standard swivelling push tool on larger work. This is an interesting idea I could use with my own scissors knurl.

I think Miller got it dead right first time, and I don't think modern versions are materially different from his designs.

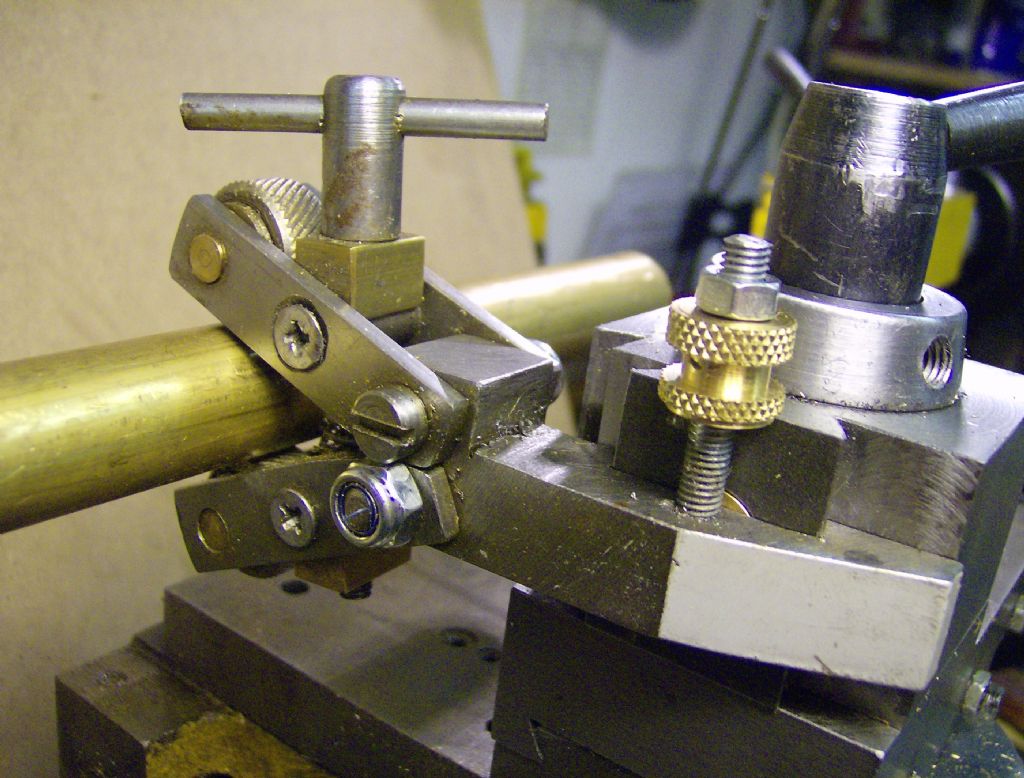

I also feel that the forces required for knurling are sometimes over-estimated. My own knurls use a high-tensile M4 bolt to apply the knurling pressure and have lasted years. Both the examples below were push-knurled on a mini lathe without distressing it, and you can see how flimsy my scissor knurl is! I'll let others be the judge of the quality of the results…

Neil

Clive Foster.