Gosh Gary, nearly missed your post. Perhaps because it's your first it was delayed and never got into 'Latest Forum Posts', which is what most of us keep an eye on.

Not familiar with the Katsu badge but it looks like a fairly typical mini-lathe, somewhat cheaper than most examples.

Mini-lathes do sometimes develop problems with the motor or the control board, usually caused by overworking or because swarf has got inside the electronics. You may have been unlucky and got a dud; blowing fuses after a rest isn't a good sign. Might condensation be a problem?

If it's new contact the seller.

If out of warranty what you do next depends on your resources, in particular can you do basic electronic fault finding and use a soldering iron?

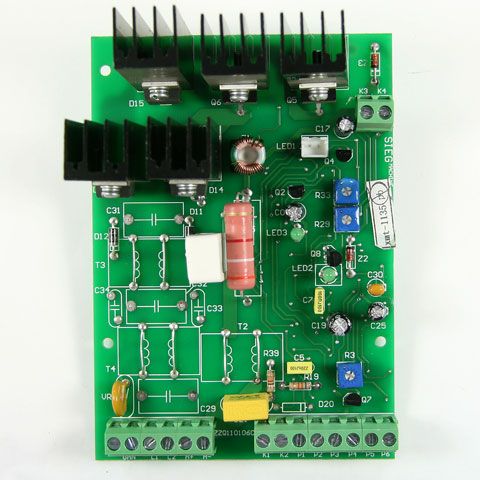

Step 1. Unscrew the plastic box holding the controls and move it enough to reveal the electronics. Check carefully for swarf and signs of burning or other damage. Chief suspects are the power MOSFETS, electrolytic capacitors, and the bridge rectifier. In failing these might blow out parts of the copper track on the circuit board. Shorts can be tested with a multimeter, and the offending components replaced & tracks mended with simple soldering. The parts are readily available on the internet. Except it's not simple if you don't have the skills or the tools! Or you might be lucky and fix it by removing some swarf.

Step2. It's possible the motor has failed. Check by disconnecting it from the control board and applying the leads to a 12v car battery. It should turn slowly. If there's a big blue flash and smoke you need a new motor. These are readily available. If nothing at all happens, you probably need a new motor. (They should start with 12V but not always.)

If the board failed, the motor should be OK. If the motor failed, there's a good chance it killed the board as well, especially those MOSFETS.

If mending electronics isn't your thing, you can buy spare control boards and motors and fit them yourself. Carefully note where all the wires go before removing the old board, photographs are good, and plug them back into the new board. Changing the motor and fitting new electronics is fiddly rather than difficult, what makes the job really hard is rushing in, ripping all the connectors out, and then guessing how it might go back together. Don't assume that the old and new wiring is identically colour coded, in fact don't assume anything.

It's also possible to install a different motor and a generic DC motor controller from ebay or such. Easy enough if you know how, but not everybody does!

Unfortunately I no longer own a mini-lathe which makes it difficult to give precise instructions. But plenty of other forum members should be able to suggest detailed help. I hope they'll spot my reply and improve on it.

Dave

Edited By SillyOldDuffer on 02/06/2018 11:05:13

Neil Wyatt.

Neil Wyatt.