I've always thought that if people were meant to fly we would have been born with feathers! I only know 4 flyers and they've all been in crashes, two of them bad ones. An uncle was in two "minor" incidents, no one hurt but the aircraft were written off both times. All of them due to pilot error, we humans can be very unreliable. Now I have to worry about the ground crew using the wrong oil as well!

Back to hot air engines, I tried flushing the first set of ball bearings used on the Coffee Cup engine with acetone and it initially helped. But only for a while. The bearings eventually failed, mainly due to sideways forces, but there was also a gummy residue in the race. I think this might have been the remains of the rubber seals.

Looking online later for replacements I found that these bearings come in a range of different types. Now I believe flushing may or may not work depending on the bearing you happen to have. There isn't a universal answer, you have to experiment.

I had a frustrating afternoon machining graphite for a new piston. It's the first time I have worked with graphite. Apart from being very messy it wasn't difficult to machine. Unfortunately the diameter of my first attempt was exactly 1mm too small. That's what I get for trusting my mental arithmetic.

My second attempt went very well until I broke it getting ready to part off. I bumped the cross-slide into the work when I meant to retract it and graphite's not very strong.

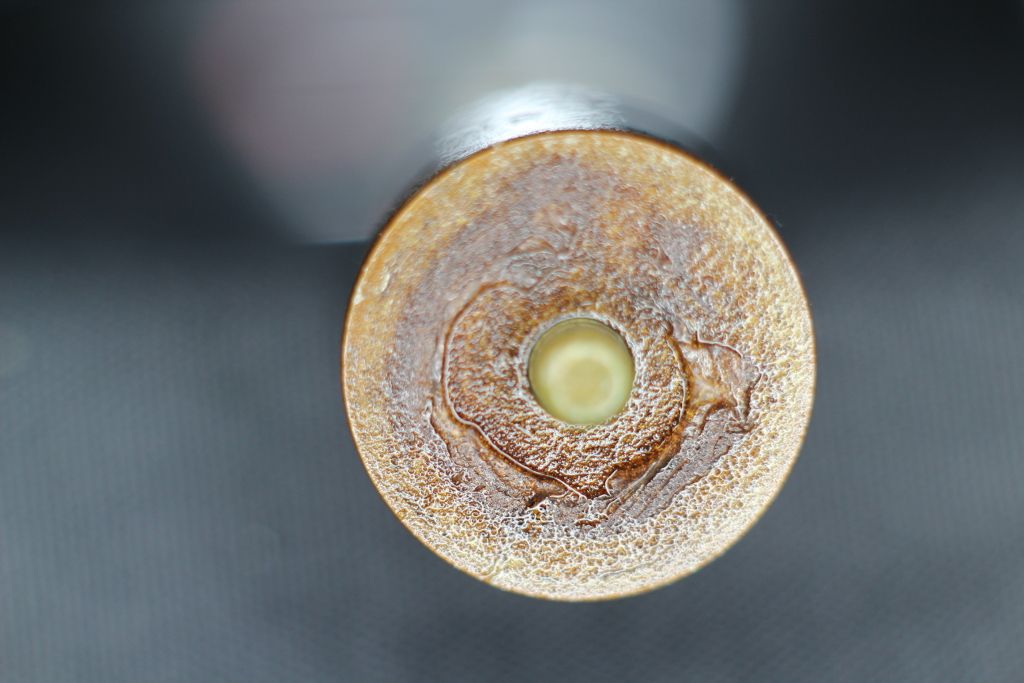

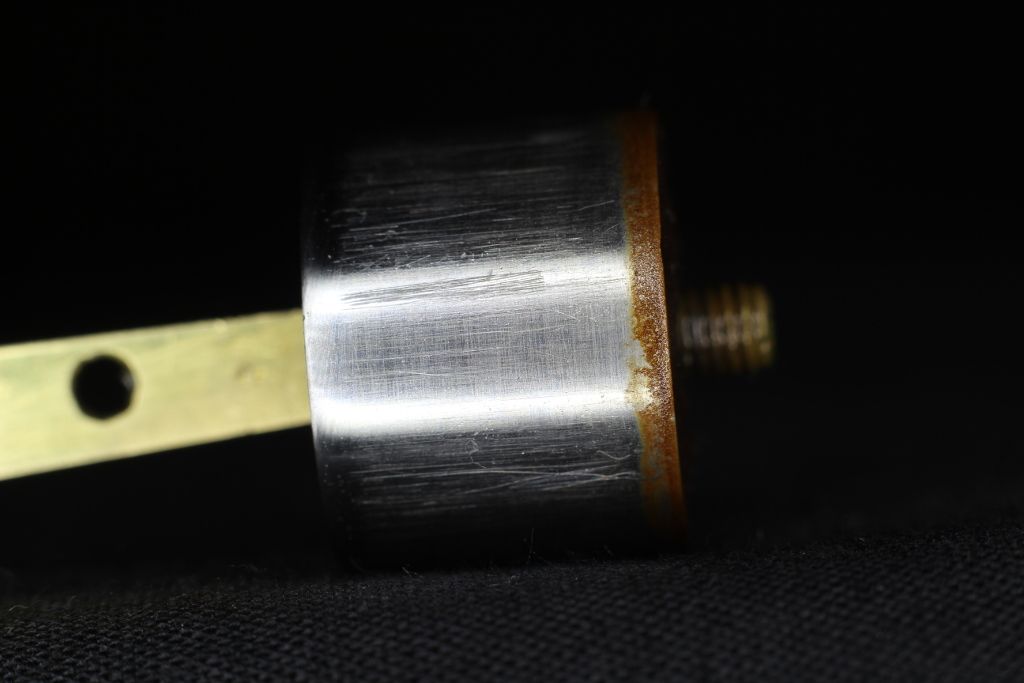

The third attempt is a near failure too. I took just a little too much off leaving the piston a tad loose in the cylinder. Although the engine works with an undersized piston I shall have to make another one. More mess.

The graphite piston seems to have solved my corrosion problem. Despite a strong smell of vinegar there is no sign of scratching or corrosion after a 40 minute run.

The engine spent the last couple of days sat on a radiator in the hope that the sealant would finally cure. It seems that completing the cure needs a higher temperature than my central heating system.

On the hot-plate at 40C there's still no trace of vinegar. But at 102C the engine reeks of it. I may try baking it in an oven.

I have, of course, got a new problem. How do you tap Graphite? Jan Ridder's design calls for an M3 tapped hole through the piston. I drilled a 2.5mm hole in the piston and tried to form the thread with an M3 tap in the usual way. At first the tap was reluctant to cut, then it started in squishy way, but most of the thread stripped just as the tap was about to finish. The flutes were clogged with powdered graphite.

Is there a preferred way to tap a soft material like graphite?

Thanks,

Dave

Ian S C.

Well that's one way of putting it.

Well that's one way of putting it.