with miniature injectors we unfortunately have to deal with lots of bad practice and faulty accessories.

in the last 9 months ive made new steam cones for someone who used far too strong a solution of citric acid to clean his injectors which a club member of his told him needed cleaning after every run. substantial amounts of the ends of the steam cone nozzles had disappeared as a result!

one friend sent me 2 excellent Gordon Chiverton injectors saying they wouldnt work. i tested them and found nothing wrong with them. his description of attemping to operate and what happened at the overflow was better than most and i suggested his steam valves/passages through same were too small which proved to be the case.

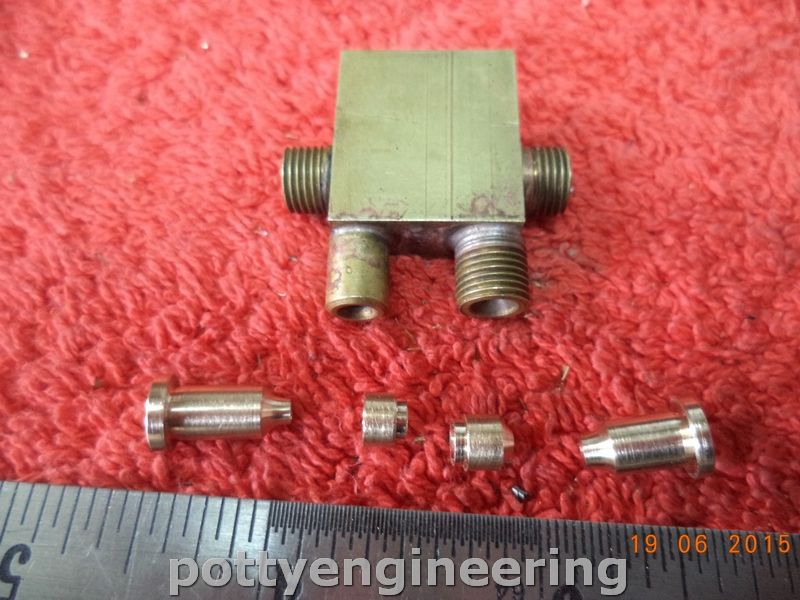

another friend sent me 2 injectors to sort out. one of these injectors had been cleaned by poking a drill through the steam cone – unfortunately it had also gone through the combining cone! the other one had something poked up the overflow and damaged the entry to the delivery cone. replacing combining cones is never satisfactory in my experience so i sent him a new one, tested, and sorted out the other one with new steam cone and delivery cone, also tested. 'wont work' was the subsequent report'! turns out his loco cab obstructed the steam valve handles so that they couldnt be opened more than 200 degrees ie less than a whole turn!

i have frequently had people ask me 'why doesnt my injector work?' 'have you fitted a filter to the water supply side' i ask. 'No' is the reply!

i understand there is something in the current ME about injectors – i havent bought my copy yet – so will be intrigued to see what it contains!

cheers,

julian

julian atkins.