Posted by duncan webster on 01/09/2016 23:18:06:

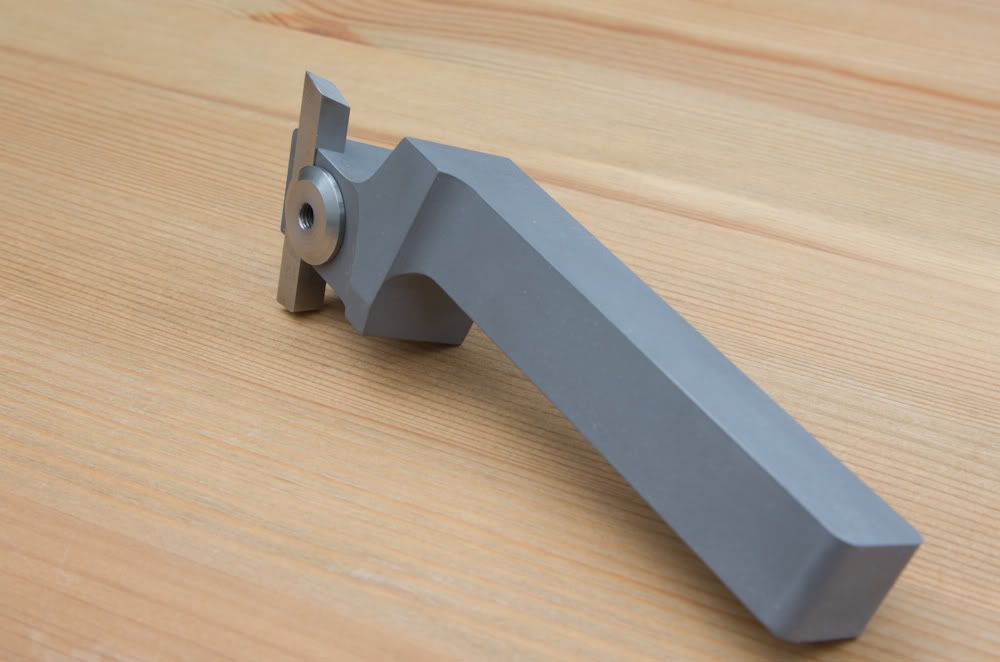

The Eccentric or similar toolholder makes it dead easy to get the right geometry, but if you grind the same geometry on the end of a tool held conventionally you'll get the same results. It just takes longer, and sooner or later you have to grind away the whole end of the tool and start again. There is another one called the Wimberly

**LINK**

I have no experience of this but the concept appears to be sound, in fact I'm thinking of making one for my Perris.

If you're a member of an ME club ask if anyone has got a tangential holder you could borrow to try.

Edited By duncan webster on 01/09/2016 23:20:46

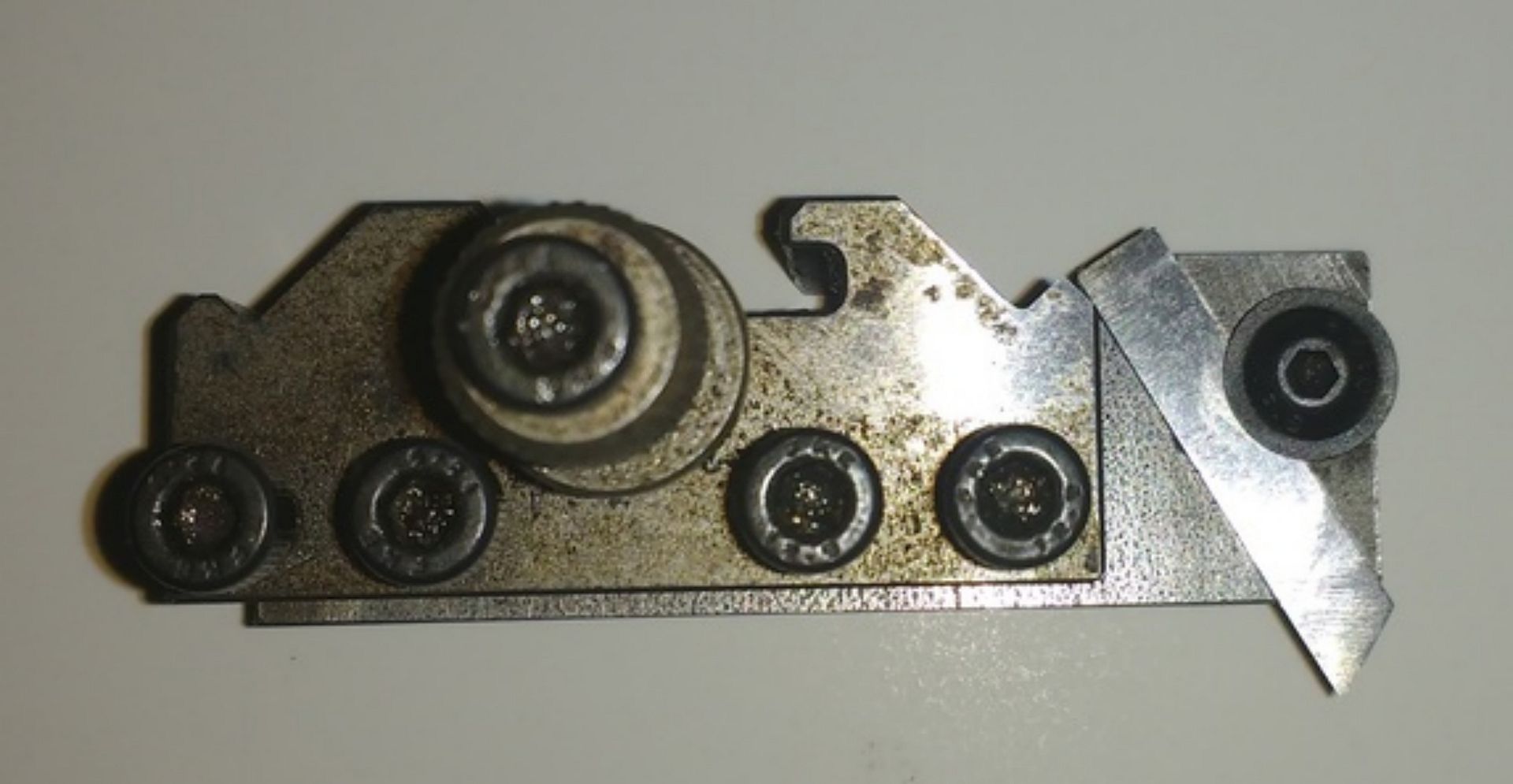

I have a Wimberly but I'm still trying to figure out a practical way of holding it – the size of the head of the casting plus excess HSS sticking out of the back gives it about an inch overhang in a four-way toolpost and means it could only be used for small diameter work. Equally it would need a 'special' holder for the QCTP and still overhang too much. This is off the Wimberley toolholder website:

To compare I measured the overhang (beyond toopost front) of a few tools:

- Hand ground HSS 10mm

- TCT tipped tool in QCTP holder 12mm

- Tangential built into QCTP holder 10mm

- Wimberley as supplied 25mm

- Wimberley with HSS cut in half (estimated) 17mm

So the wimberley as supplied reduces the diameter of work I can tackle by 26 -30mm.

What sort of overhang does a 'normal' tangential holder have?

Of course I could cut the HSS in half but that would only give a small gain and defeats the object of an easy sharpen. long lifetime tool bit.

My conclusion is that the Wimberley is a great idea in principle but in practice it will be best for small work on large lathes unless you have a long-travel topslide or are willing to use a custom toolpost to hold it.

Edited By Neil Wyatt on 03/09/2016 10:20:51

Jon Gibbs.