As the name suggests, a roughing tool is intended for removing larger amounts of metal. How much will, depend on the machine, its rigidity, power and the rigidity of the tool holding. You may take a 6 mm deep cut on a big lathe, but that would probably wreck a mini lathe. (The mini lathe Operator Manual says that for roughing do not exceed 0.010" (0.25 mm), although used with discretion, deeper cuts are used by many )

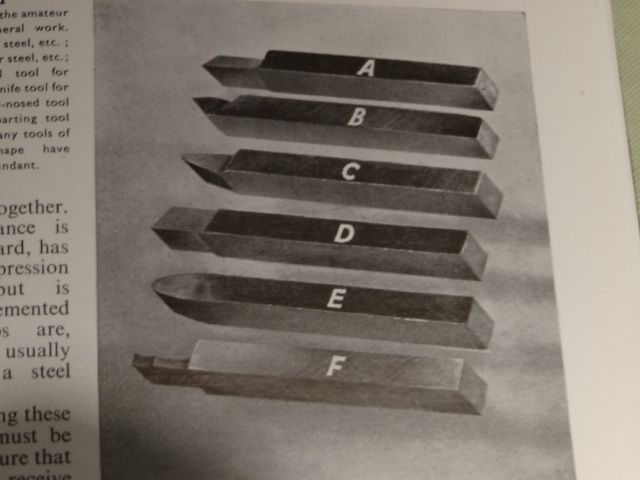

A rougher can be a plain knife tool.

The greater the length of the edge involved in cutting, in general, the more prone to chatter it can be.

Chatter can be induced by grinding the tool to the wrong clearance or rake angles for the material being machined.

Too large a top rake can induce dig ins or chatter because of the deflection of the tool caused by the cutting forces.. Parting tools can be particularly prone to digging in. (I use a parting tool with no top rake, in a back toolpost.. But this is not always possible with some lathes )

A finishing tool, will have a small radius on the cutting edge, which combined with a fine (low ) feed rate, and shallow depth of cut should produce a good surface finish. Lubricants can improve surface finish, even when the optimum speeds and feeds are being used. Ideally, the radius should be a little larger than the depth of cut and feed per revolution.

What was shown as a finishing tool is, in my view, a Left Hand tool, used in certain circumstances, to cut away from the Headstock.

The hand of a lathe tool is that when viewed on the cutting end, not the shank.

Unless the tool is set on the centre height of the lathe it will not cut properly.

It might be worth making a Centre Height Gauge, so that tools can be set to be at the correct height.

+1 for L H Sparey "The Amateurs Lathe" Majors on the Myford ML7, but the basic principles are still the same.

Also, Ian Bradley "The Amateurs Workshop"

The Workshop Practice Series includes two books by Harold Hall (A former MEW Editor ) which will be worth studying.

No.34 "Lathework" and No. 38 "Tool and Cutter Sharpening"

Two other MEW Editors have written books on the mini lathe, David Fenner, and the present Editor, Neil Wyatt.

All of these will give advice on grinding tools, setting up and using a lathe.

You will find a set of Zeus charts invaluable. I bought mine in 1958 and still use them regularly.

Another very useful reference book is Tubal Cain's "Model Engineers Handbook"

Money spent on books may well be repaid in the savings by avoiding scrap material or poor results.

Riding a hobby horse, quite a few on here are, like me, enthusiasts for the Tangential Turning Tool which is normally reserved for finishing in my shop, although deep cuts can be taken. For this you really need a Centre Height Gauge for setting the tool height, Grinding the tool is easy, with only one face to grind.

HTH

Howard

Howard Lewis.