I love asking questions on this forum. Experts sort out out my problem while I'm boozing at a family jolly.

Bit more background, Dick and Clive H identify the component, and with Gary are all thanked for focusing my attention on why it keeps failing!

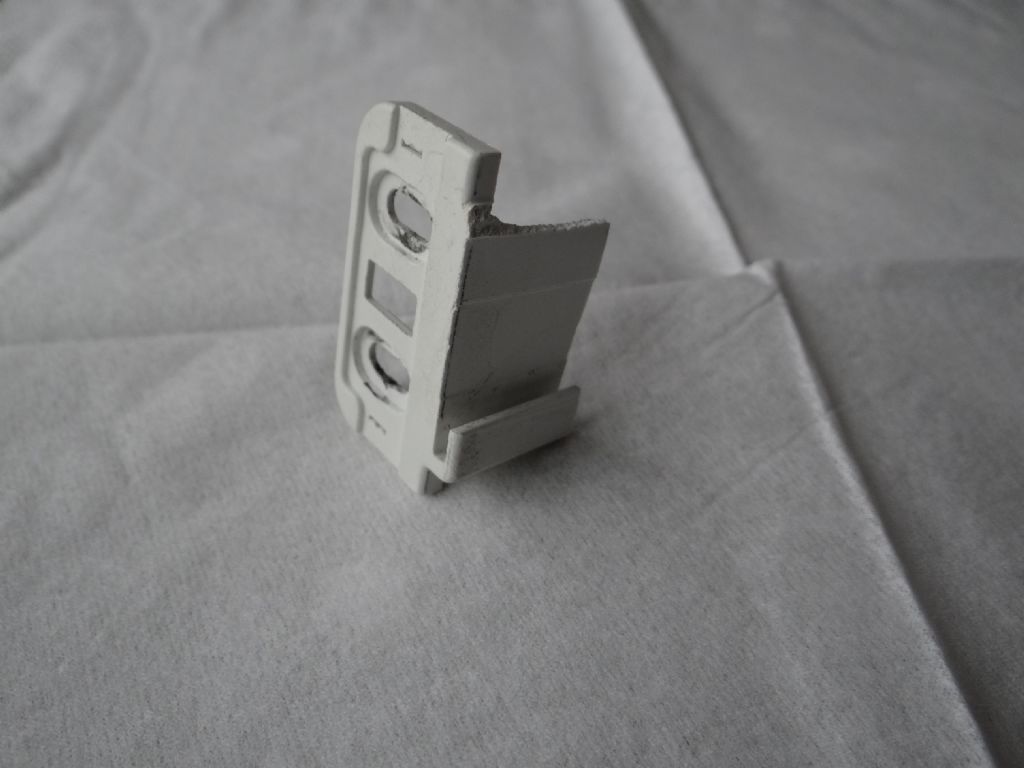

The fridge/freezer belongs to my sister and is fitted in a cupboard. The fridge is on top and its door is joined top and bottom to the cupboard via slider rails. It is the lower component that breaks – they last about a year. The cupboard door has a hand grip running along the lower edge that people naturally use but it puts most of strain on one flimsy part, which eventually breaks. The close-up shows how thin the part is where it connects to the slider! (Bottle-top for scale)

The fridge/freezer belongs to my sister and is fitted in a cupboard. The fridge is on top and its door is joined top and bottom to the cupboard via slider rails. It is the lower component that breaks – they last about a year. The cupboard door has a hand grip running along the lower edge that people naturally use but it puts most of strain on one flimsy part, which eventually breaks. The close-up shows how thin the part is where it connects to the slider! (Bottle-top for scale)

Clive F's comments about 'barely enough material to do the job' and clearance are very relevant. It may be possible to beef the part up, though Clive H is right to worry about breaking the slide rail which is also flimsy, and he's likely right about the vacuum as well. More investigation needed.

For solutions, I'm spoilt for choice:

- Modify an existing tool like a woodruff cutter (Ed, Jason)

- Make a tool (Neil's Rufus Roughcut & Ian's butchered hacksaw blade)

- Misuse a tool ( Derek's router bit & Adam's key cutter.)

- Plane the slots (Jason & XD351)

- Hacksaw slots(Les & Mick)

- Make in layers & glue, screw, or solder ( Tim, Duncan & Clive F)

- Fold from metal (Blowlamp) – possibly how the part would have been made before plastics.

What happens next depends on what's in my junk box: a Rufus Roughcut or fly-cutter most likely.

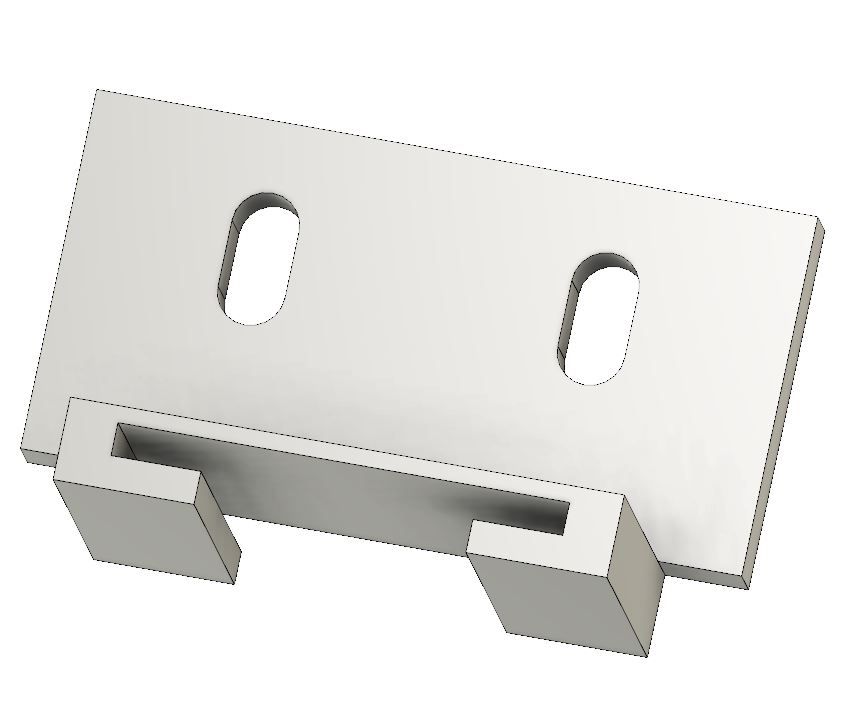

Special Mention in Dispatches for Neil's 3D printer. I thought this was a good idea but it turns out my kids are unhappy about me blowing their inheritance on 'toys'. Put to me vigorously that a man with a garage full of tools should be able to fix a fridge door with what he already has…

Watch this space. Be a week or two but I will report again!

Dave

pgk pgk.