Posted by Neil Wyatt on 21/11/2015 12:20:03:

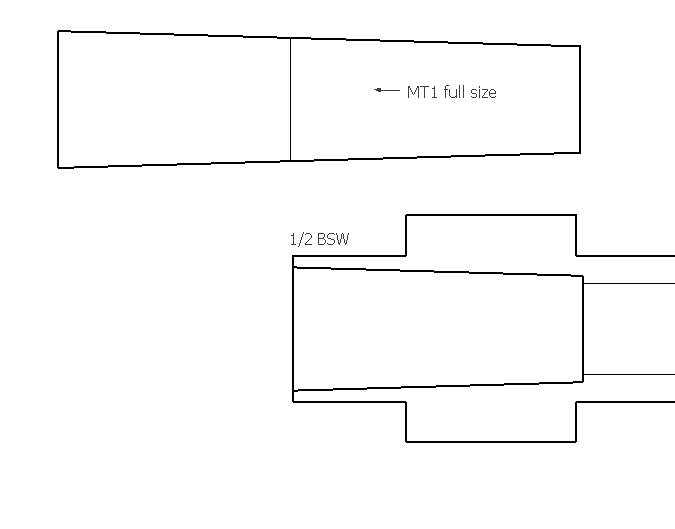

Once you have allowed for the nose thread you have less than 0.4" to play with, so even with an MT0 the wall thickness under the thread is pretty small, MT1 is a non-starter.

Neil

I agree with Neil. No chance even with just part of an MT1 going in. There isn't enough meat there.

About all you could put in the end is an ER8 collet taper and make a nut probably forgetting the self extract feature and tapping them out with a drift down the hole in the spindle.

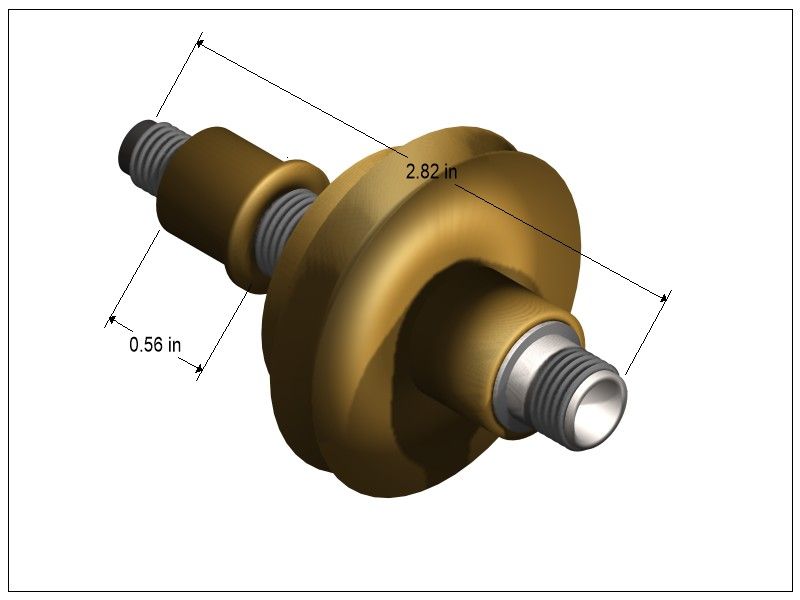

The spindle nose would probably take up to ER16 but the collet chuck would have to be made, both threads and ends cut in one setting and the collet cone taper added when it's mounted on the spindle.. As there is no register on the spindle nose the thread fit would need to be pretty precise. Really one setting is essential anyway.Threads do tend to self centre under load but it wouldn't be wise to allow too much clearance. The thread angles would need to match. Maybe screw cutting and just cleaning up with a tap and die using a tap that is actually on size and a split adjustable quality die.

At least it's bsw so there may be some old accurate stuff around. New modern taps tend to be oversize. Die's a bit mixed and holder usually bang on size rather than being a bit over so that the die can be opened up a bit.

At least it's bsw so there may be some old accurate stuff around. New modern taps tend to be oversize. Die's a bit mixed and holder usually bang on size rather than being a bit over so that the die can be opened up a bit.

If you do make one I would be inclined to use leaded free cutting mild steel. Things are less likely to bind together. Cast iron is better in that respect though. Best to buy the nut if you do this.

John

–

Edited By John W1 on 21/11/2015 15:09:25

Edited By John W1 on 21/11/2015 15:13:56

Rainbows.

At least it's bsw so there may be some old accurate stuff around. New modern taps tend to be oversize. Die's a bit mixed and holder usually bang on size rather than being a bit over so that the die can be opened up a bit.

At least it's bsw so there may be some old accurate stuff around. New modern taps tend to be oversize. Die's a bit mixed and holder usually bang on size rather than being a bit over so that the die can be opened up a bit.