Well, it does seem that things take time…Sometime, a LOT of time –for some…

What I did in the last 320 days – seven eighths of a year, to be 'exact' –

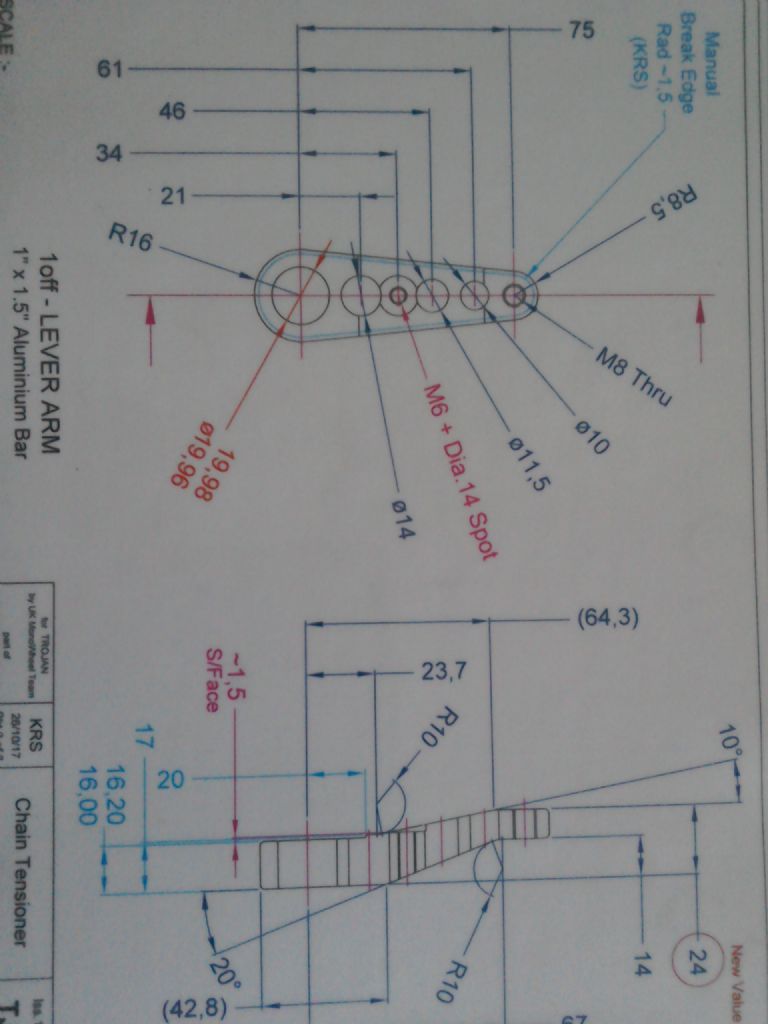

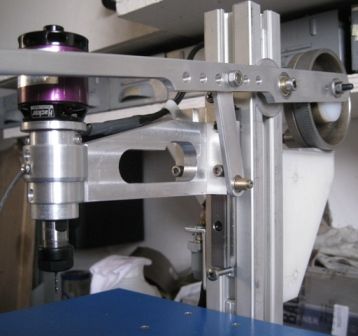

Made a High Speed (30,000RPM ) sensitive drill press :

Made a Dynamic balancer using accelerometers to balance the motor Rotor, using the excellent Miklos Software:

Made a Large Droplet Spray coolant Applicator:

Purchased a Nice NEW EMCOMAT 14D lathe:

Purchased an Old ALBS 2S shaper:

And Refurbished it totally, remade the vertical slide dovetails that were smashed, and fitted a computerised control to it, automating the whole machining process.

Then refurbished totally my two EMCO FB2 Mills, and made swarf/Splash Guards for them – seen back-to-back here:

And then refurbished totaly my EMCO V10P lathe, Modified the cabinet to have cupboards and draws, and developed an Electronic Leadscrew to enable fully automatic thread cutting of any thread pitch.

The Lathe Pre- refurb:

Cabinet in process:

The V10P after refurb, with Electronic Leadscrew system fitted, and DRO on X and Z axes.

The cabinet cupboard and draw mods were so useful, that I did the same to the EMCOMAT 14D cabinet:

Then I resurrected an IDEAL Bandsaw Blade butt welder – works very nicely indeed!

Since the Electronic LeadScrew (ELS) , which also does electronic feed for surface machining, was so successful and a total stress-free threading process, I am in the throes of implementing the same system on the EMCOMAT 14D lathe. This will be complete in the next week or so…

I have also helped Paul White implement the same ELS on his 100 year old lathe – he did post this on the ME site a while ago – he is a Happy-Chappy!

And now I am helping him implement a similar system on his 'Jacobs gear Hobber' – eliminating all the interceding gear train driving the gear blank.

Oh, and also chased a dozen or so Lions around the desert, helped dart and collar them with satellite tracking collars, flew a few Unmanned Aircraft missions for the Ministry here, over the National Parks in aid of the anti-poaching Brigade, etc…

Next project – maybe not done before end of 2017 – is to make a 'head' specifically to do drill bit sharpening on my Tool and Cutter grinder, bits from 0.5mm up to 6mm max – along the lines of the METEOR drill grinders…

And maybe post a users impression of the EMCOMAT 14D lathe – so far a SPLENDID lathe, perfect out the box…

Procrastination is for Sissies…

And I am 'Retired'…

Joe

James A.