I have an 80mm refractor telescope which came screwed with two screws to a bracket that has a dovetail foot. I replaced the foot with telescope rings to make it all firmer. But now I need a lighter system and seem to have lost the original bracket.

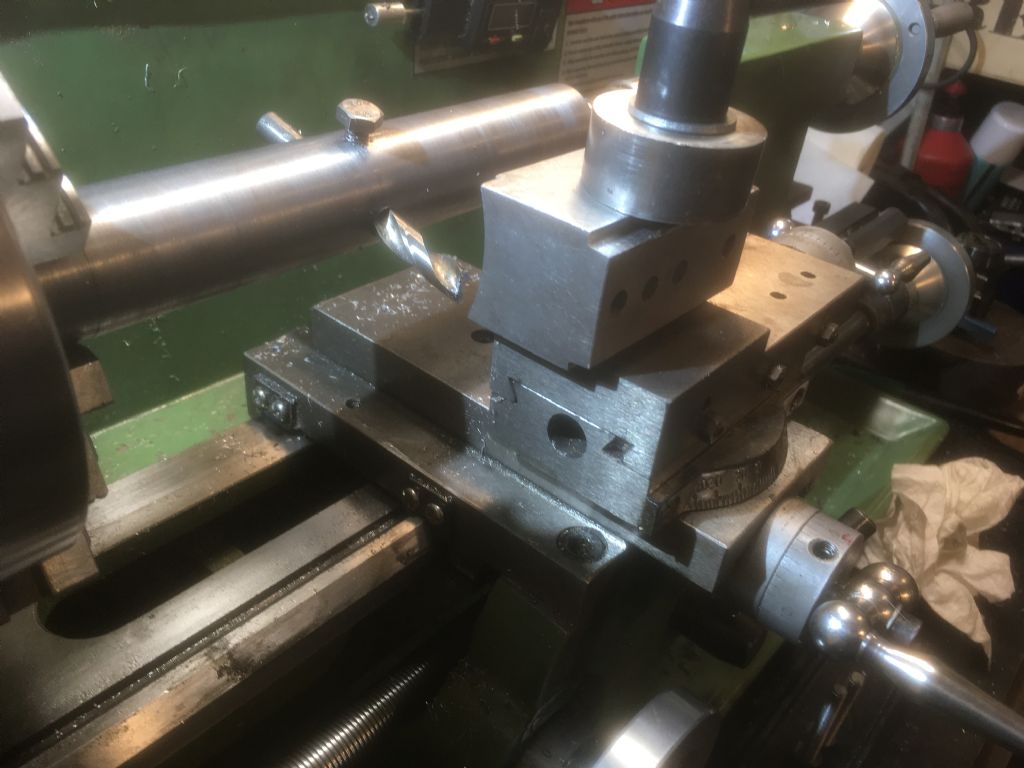

I can do the dovetail and the rest of the bracket but I need to produce a nice clean 45mm radius groove along the top of the bracket (around 30mm wide) to sit the optical tube in. I have a milling table for my mini lathe and was hoping to mill a long internal radius slot along the top of an aluminium block.

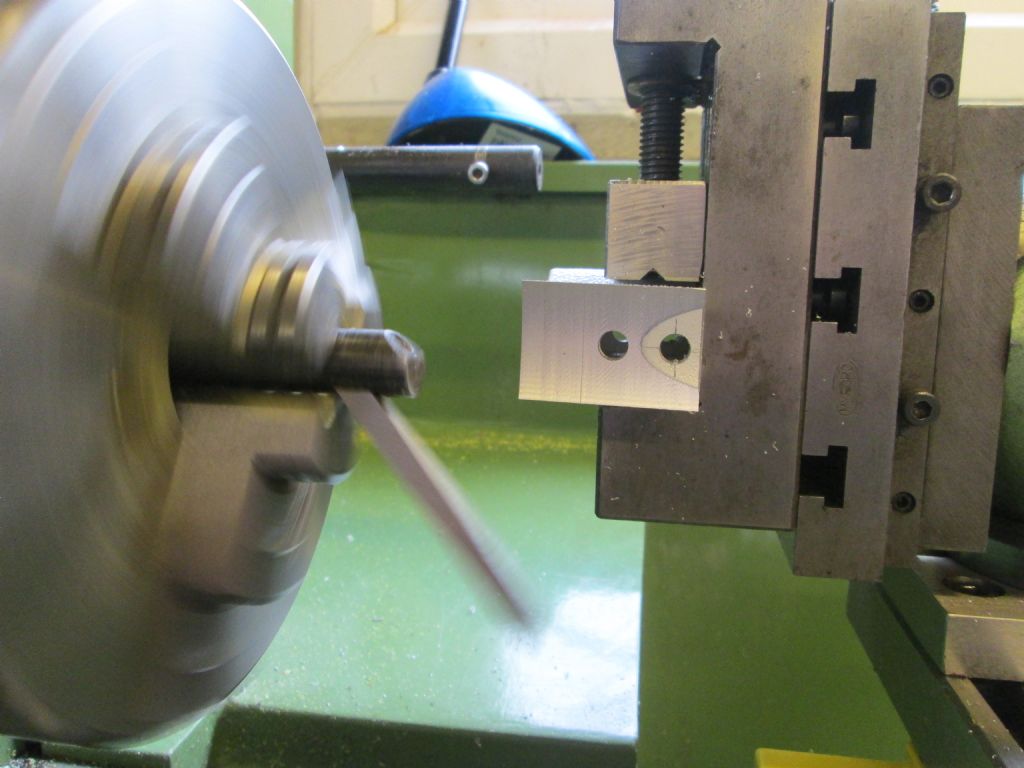

A fly cutter with a long arbor could do the job but the lathe is a bit flimsy IMO. I was thinking I could use a long sort of boring bar, supported at the tail stock end to hold it steady and use a flying cutter (carefully).

Alternatively, I could try to form a flat plate round a suitable pipe to get the curve and sit it on top of my bracket.

This is the sort of thing I could imagine would be needed to fit a cylindrical boiler for a steam engine so people must have already solved this problem. Problem is to choose the best search terms for information straight from the internet.

Any ideas?

Edited By andrew lyner on 04/11/2019 17:34:53

andrew lyner.