If you don't mind modifying the machine, then the advice to turn up new studs to carry the plastic gears from the SC2 or SC3 mini lathes is a good one.

The plastic gears will be cheaper than metal, and fairly easily available. But there is no 100T available, 80T is the largest supplied. I cut my own 100T gears when I wanted to obtain a finer feed on my SC3.

And if you ever want screwcut Imperial threads, you will need a 63T which is very likely to be metal.

The faa that the gears are from a lathe with a 1.5 mm Leadscrew is of no consequence. What matters is the ratio between the Mandrel and the Leadscrew.

A 1:1 ratio on your Hobbymat will produce a 1mm pitch thread, where the same set up on a lathe 1.5 mm pitch Leadscrew would produce a 1.5 mm pitch.

If you wanted a 1.5 mm pitch, you would need to set up a 1:1.5 ratio, such as a 60T driving a 40T on the Leadscrew, with any suitable gear between as an Idler.

Brian Wood's book, "Gearing of Lathes for Screwcutting" explains it. But in the chapter on the mini lathe, you will need to use mental arithmetic or a calculator to modify the numbers for either the charts for the 1.5mm Leadscrew, or the 2 mm pitch Leadscrew. The 2 mm chart is probably the easier since you have only to multiply or divide by 2!

Howard

Ian Johnson 1.

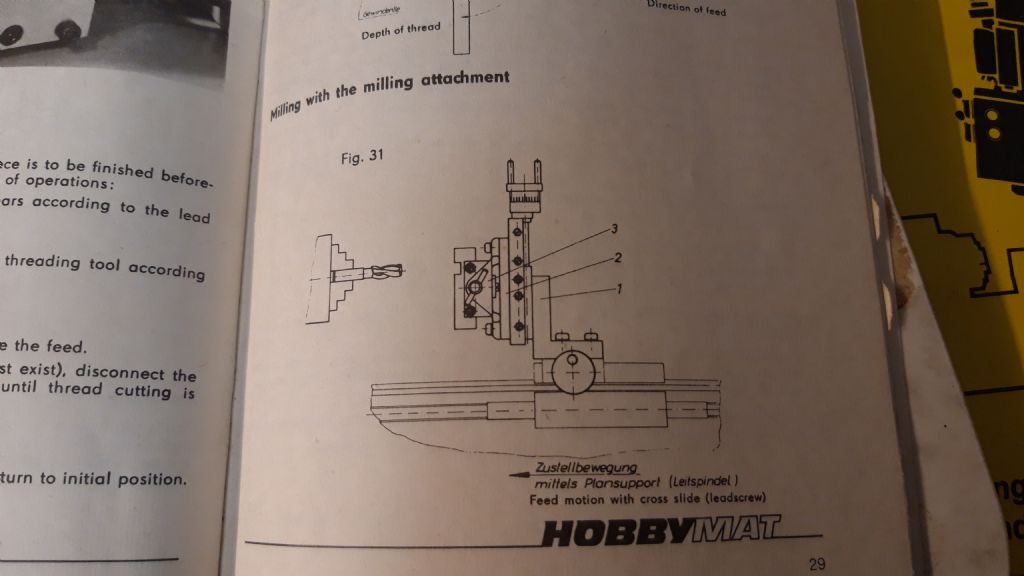

Also also, I can't see how the mini vice would bolt up secure to the original plate unless I don't have the original mini vice.

Also also, I can't see how the mini vice would bolt up secure to the original plate unless I don't have the original mini vice.