Hi Andrew,

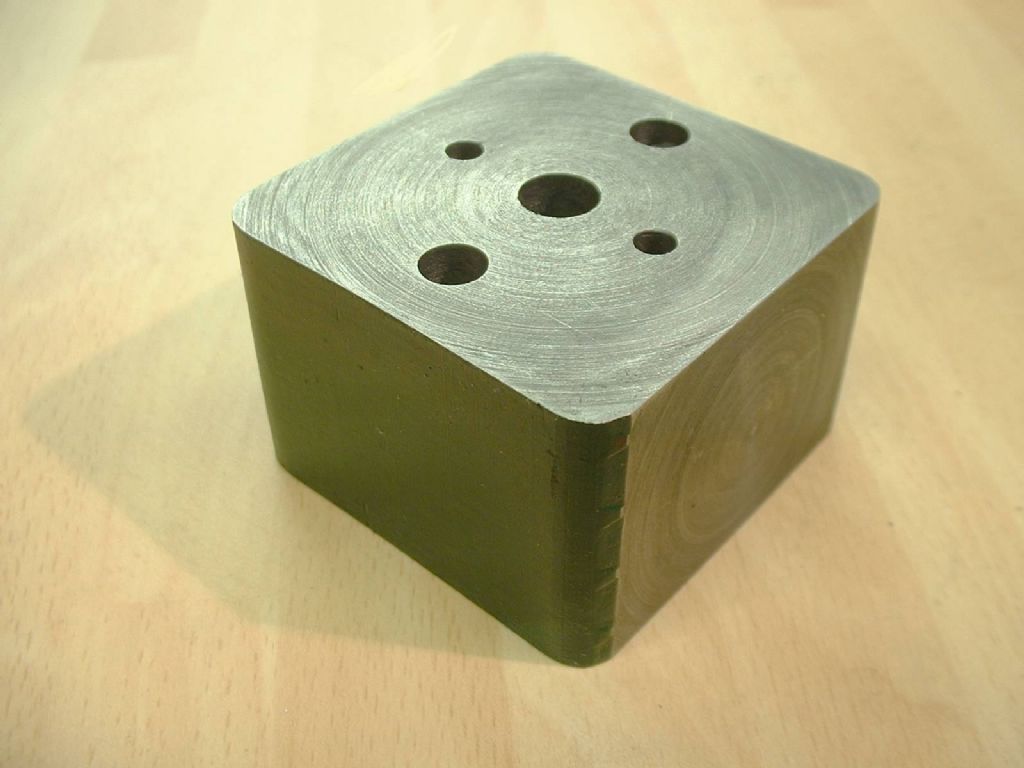

Quite interesting to read back these old threads sometimes. I'm afraid I don't have a Warco (e.g. Sieg) lathe – so cannot answer that part of your question directly. However – unless the vertical slide has been made specifically for use on the lathe you are fitting it to – then you will probably find that some form of adaptor plate will be required (simply to match the holes in the vertical slide to the cross-slide). In fact it can sometimes be useful to make an adaptor plate anyway – to avoid needing to tighten a couple of T-nuts too much on the cross-slide for instance (by using more nuts & spreading that load) or to lift the vertical slide so that more movement is available when a vice is fitted.

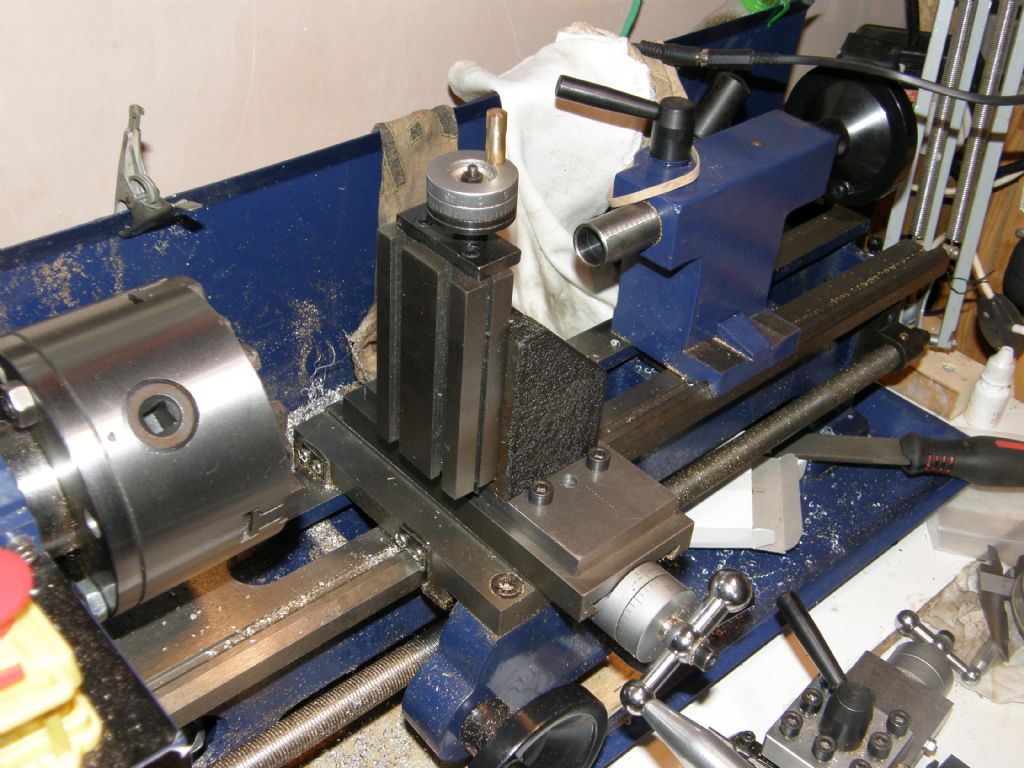

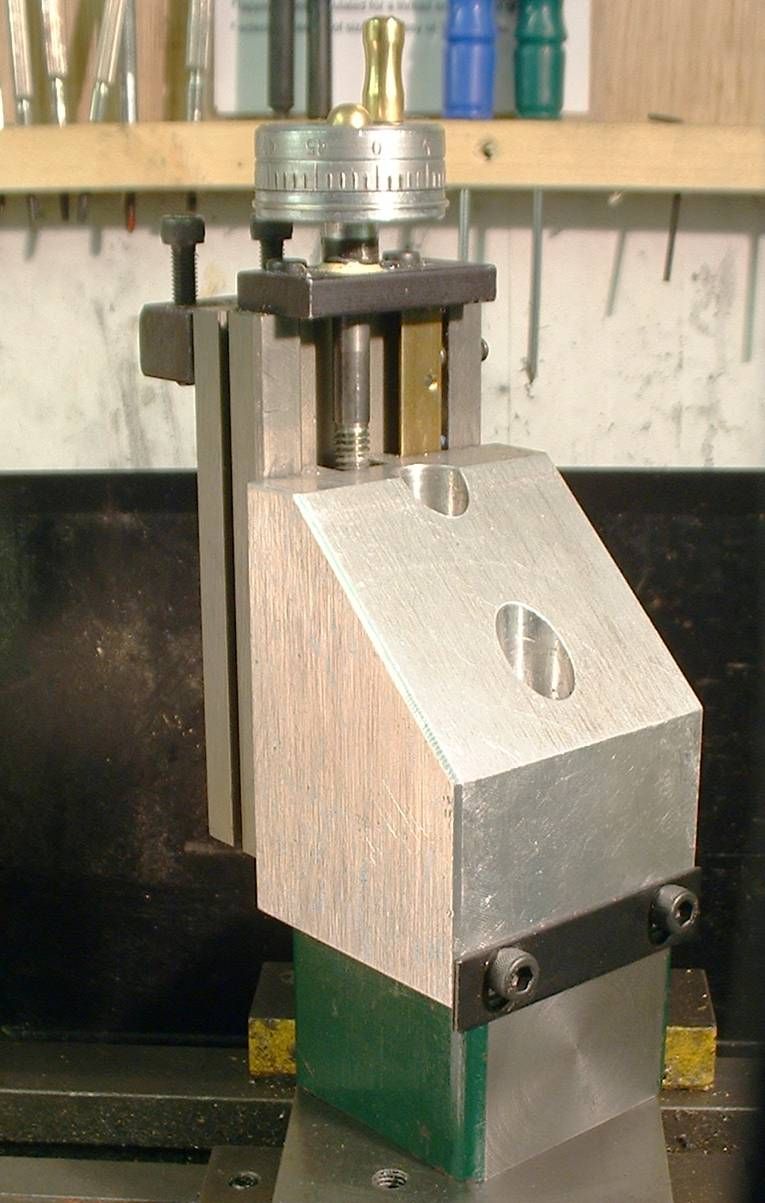

My Chinese Vertical slide had a swivel base (single axis) but I cannot immediately recall ever using it – usually bolting the slide directly to my myford (S7) adaptor plate. Nor would I be very keen of those (Myford type) slides that rotate in several axis. The vertical slide mounted on the cross-slide is already fairly flexible in nature without introducing other flex points/joints (others may disagree with me on this though).

I might also mention that before I had a vertical slide, I used to do quite a bit with a simple DIY angle plate bolted to my (original Lorch lathe) cross-slide – which became peppered with bolt holes – with various thickness of packing pieces to set the work piece height or adjust it by a known amount. Sounds crude but it worked pretty well.

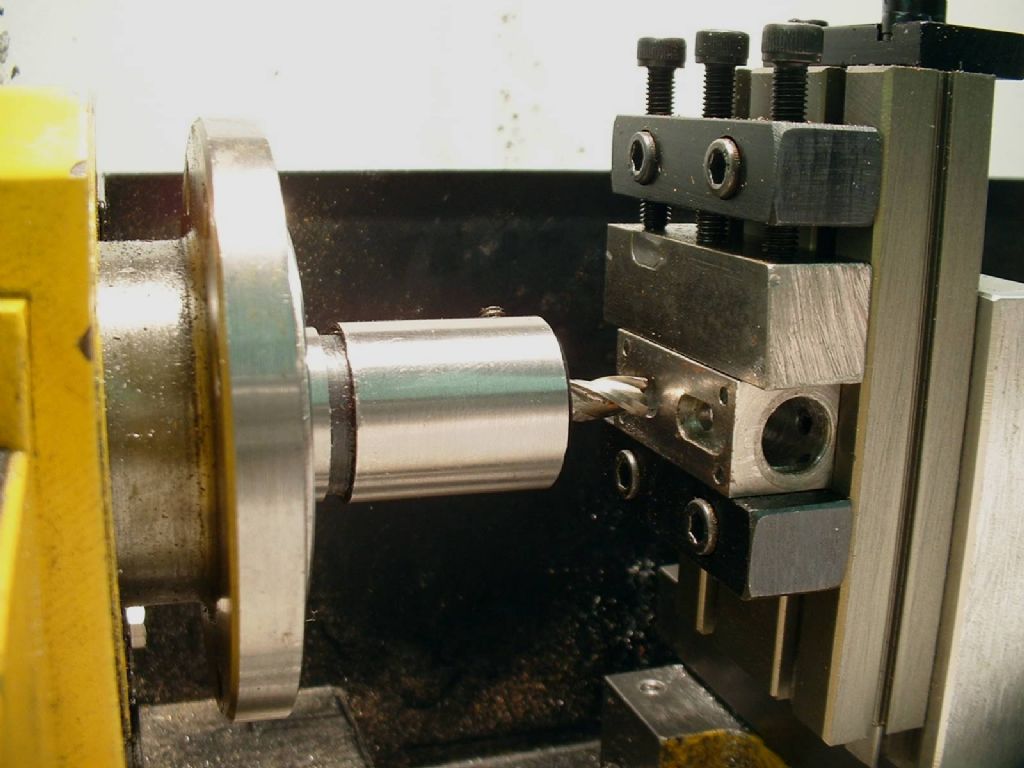

You ask about collet chucks – and I am a very firm fan of ER collets (I have both ER 16 & 32 sets) but always advise folk to fit the back-plate type ER chuck (as opposed to an MT mounted type). This will let you pass work through the chuck & spindle if you are work holding with it (which I often do) as well as adjust it for absolute truth (just in case it isn't true as it comes) and moving it to another machine – should that machine have a different MT tapered spindle for instance.

If you intend to use the ER chuck just for milling – the above is still good advice but you may only require a few collets that will take the cutters you need to use – so buy them as required I think…. I still have a few still in their wrappers after some years…

And yes – it's very common to expect everybody own a mill these days but much wonderful work was done before their ownership by home machinists was common. It may not always be as convenient to use a lathe-only approach but sometimes space & money will determine this for some folk (and in practice you might not really use or need it that often either – everyone has different needs).

Anyway – coffee break/lunch is just about over – so I'd better get on with something "really useful" before my Manager gets upset.

Regards,

IanT

Edited By IanT on 01/10/2018 13:11:10

IanT.