Hi Ian,

I have moved mine a few times and here is how I went about it. You will need an engine crane and possibly a pallet truck/pallet, you can hire the first two. Most haulage places or even supermarkets have so many pallets lying around that they'll let you have one. This is a two man operation.

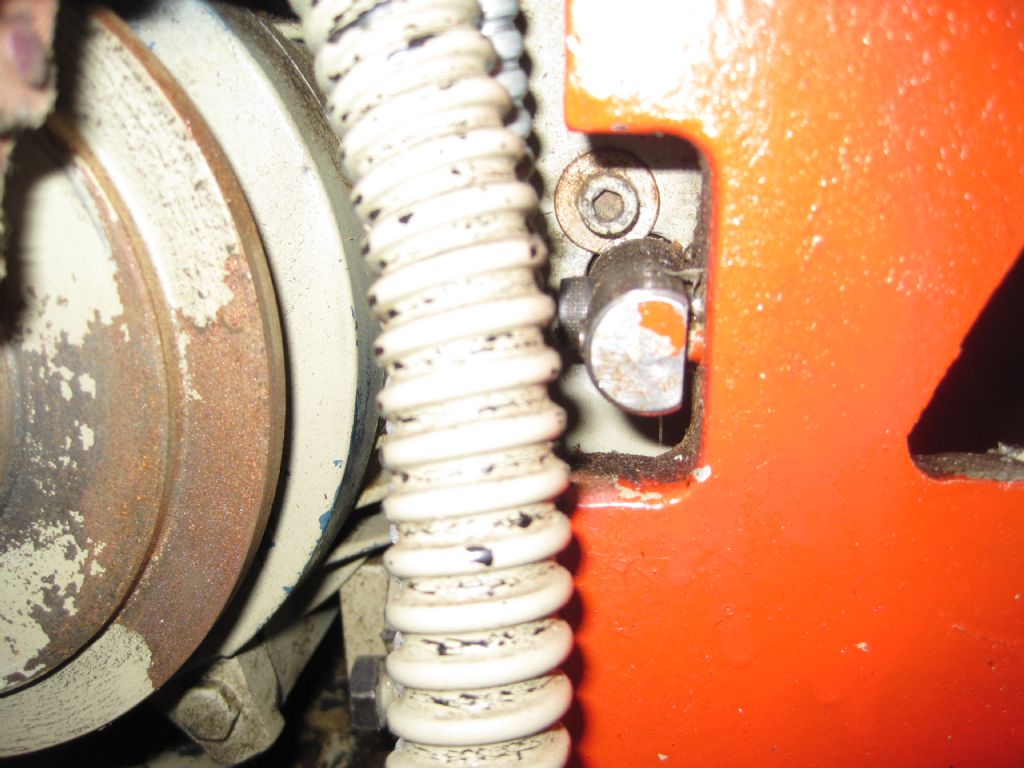

There is a lifting point on the bed, just below the chuck, You may find this has a protective grub screw threaded in. From memory it is M10. Take the chuck off the machine and thread an eyebolt into this hole. Then choke a strop through this, or a loop of polyprop rope. adjust your engine crane to reach this and bring it in from the headstock end, hook it up. Move your tailstock as far up to the headstock as you can get it, this will help with the balance of the machine as you lift.

Pump away on your engine crane. Your machine will come up headstock end first, After only a couple of inches on the headstock, the tailstock will come up. Once you have the machine in the air, two of you will be able to shimmy it into the new position, then slowly lower, carefully. Ensure that as you lower the machine it does not catch on the legs of the engine crane. If it does, disaster will ensue.

If you need to move it further, you'll need to get yourself a pallet. Chop your pallet up until it is an exact fit to the base of the machine. You may need to reinforce it a bit with some of the discarded timber. Lift as above, then put the pallet in under the machine. Lower the machine onto the pallet. Clear the engine crane and then you can get your pallet truck in. It is highly advisable to secure the machine to the pallet with a cargo strap before you move it. Take it steady, and have your helper push the machine whilst you steer it.

Carl.

Carl Wilson 4.