Wow, thats all way to much for me! I need to read all that a few times and try understand – I think I have a problem in grasping some fundamental issue here, and so the rest will not fall into place.

I dont quite follow the concept of the 'index' position – If this was a single point cutter, and I indexed the rotary table 158 times around the blank, spending time at each index position to cut the tooth, then I agree, the cutter can only fit into a slot that is one of the 158 index positions.

But in hobbing with a helical hob ( the tap) there are no 'individual' index positions. The only criteria is that a gear tooth crest must always line up with a hob trough as both rotate. Now if the gear blank diameter is too large, the 158 teeth will fit into a shorter periphery ( since the pitch of the hob did not change), and although the hob tooth should then mate with the periphery tooth 1 again, it actually cuts fresh blank – ie, putting more teeth on the blank, in the extra circumference. The chance that when the hob meets the original tooth 1 in the blank, that it mates with it, is pot luck…and so the teeth begin to be cut on top of each other and erode.

That does happen, I watched it many times over 5 or 6 blanks, and only ceases when the blank diameter is correct for that pitch hob.

I believe I understand your comment John:

,the effective pcd has changed along with the profile shape of the tooth which just uses a different part of the the same involute

curve.

But does that not only apply if you are changing by one or two teeth, sort of thing, ie, a small change to fiddle the result?

John, then what gets me is – refer your comment:

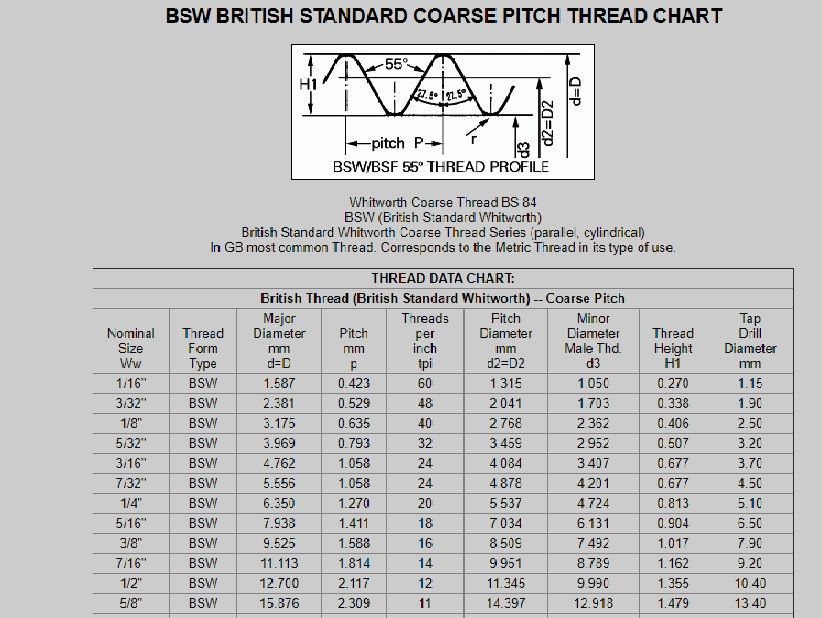

Getting back to your gear for 158 tooth on a pcd of 116.13 mm the normal od 117.60 mm

the blank od should be 118.87 and the tap/hob should in feed from this diameter by 2.159 mm.

The cut width across the face of the gear at this should be as measured 10.80 mm .

I think that these measurements agree with what you have

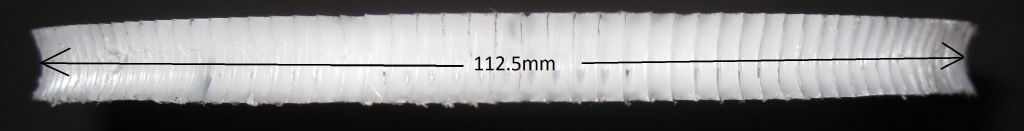

If those measurements are correct, why did my final gear, with 158 teeth around it, apparently neatly spaced and formed, result in a final blank OD of 112.5mm?

Should that not have been 118.87mm – 2.159mm, ie = 116.71mm??

112.5mm is quite some ways from 116.7mm!

Also, can you please explain where this dimension is taken:

The cut width across the face of the gear at this should be as measured 10.80 mm .

I am battling with this indexing versus spacing thing!

Pete, you said –

That's the point you will not erode all of the teeth because you're not relying on spacing but on indexing. The 4mm error is spread between the teeth but it's not added together to leave a gap at the end. On the first turn you have 158 indexes, on the second turn you have 158 indexes, and so-on. After ten turns you'll still have 158 indexes and each one will be in the exact same place as all the other turns.

Surely that is only possible if the gear blank periphery is divided into 158 equal spaces ( the teeth)? And since these spaces are directly related to the pitch of the hob, we surely have little room to fiddle the space size? And then, to fit 158 indexed positions , related to the hob pitch, equally around the blank, we need to have the blank the correct diameter.

I am sure I will see the light soon..!

Joe

Phil P.