Having spent some time evolving my pcb milling process here are a few comments.

I use FlatCam to create the CNC code from Gerber and Excellon files out of GSpark. FlatCam was the first program I tried and it does everything I need without looking further. It allows default start up and shut down GCodes to be embedded in the export code to the mill (in my case a Tormach PCNC440).

I run at 10,000 rpm (maximum possible on the 440) and at 150mm per minute with a 5.1 thou cutter. While I ramp and spiral in when cutting metal I rarely have the real estate on my pcbs to allow this luxury. I dive straight in and cut and it has not been an issue.

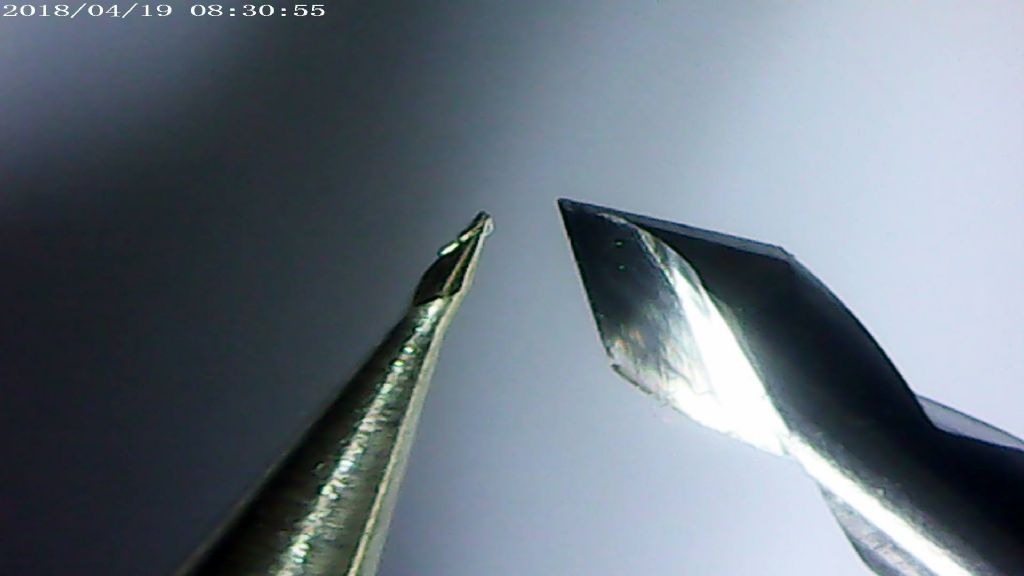

I found that tapered engraving bits to be fine providing the pcb material could be clamped flat. If the material is not flat then variations in cut depth result which in turn leads to a wider cut through the copper (think about the geometry). I tried 10 degree cutters to minimise this and found them to be very fragile. If tracking is wide this may not be an issue.

I subsequently found proper fine milling bits from Think & Tinker that which are parallel for the first section and then taper up. They can be supplied with collars so collet mounting is repeatable. They are expensive but are good if you need to go to fine detail.

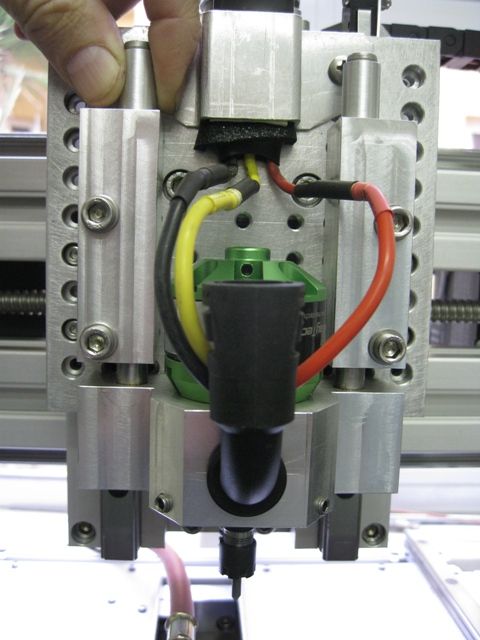

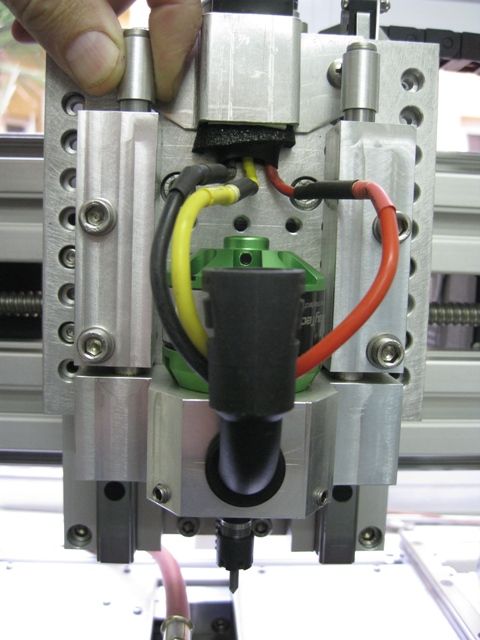

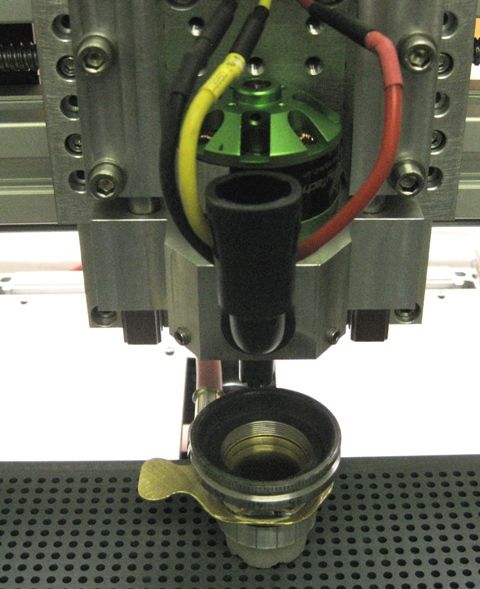

I tried various clamping methods for the pcb material to try to eliminate the bow. Single sided board is the worst as having the copper on one side causes a 'surface tension' style bowing from the laminating process. In the end I solved this by designing and making a simple vacuum table which runs off the 'hoover', This was an amazing success for a finger in the air idea. The Fusion 360 file is available if anyone who wants to try it.

The vacuum table while solving the clamping does mean it is not prudent to drill holes all the way through the pcb and potentially damage the vacuum table surface and or damage the carbide pcb drills. I therefore drill to almost break through and then go round the board afterwards with my high speed bench drill. With the centres already spotted it is a quick process.

One option that could be used but not tried as yet is to put 'gaffa' tape or similar on the pcb back side to provide a finite spacer and allow some additional depth for through drilling.

Finally I use mist coolant (via a Fog Buster) when milling the boards. This is the same as I use for metal machining (Qualichem Xtreme 250C). It helps the finish, protects the tool and also damps down the dust.

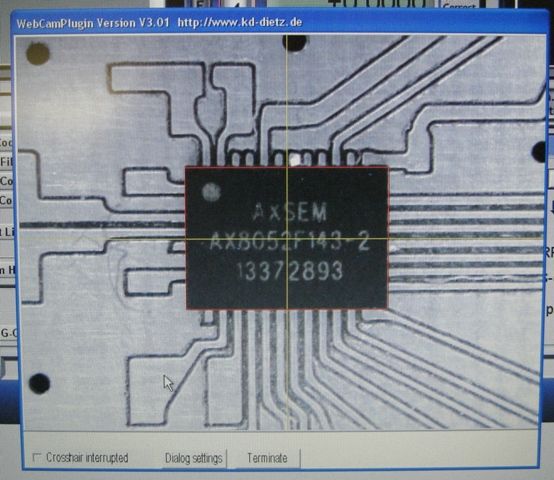

The finish straight off the mill is sometimes not too pretty but after a gentle rub over with fine wet and dry looks excellent. With a 5 thou tip I can cut very fine SMD tracking.

After the wet and dry, while the board has a bright clean untarnished finish, rub over with flux paste and then run a wide bit hot soldering iron quickly over the tracking while feeding fine solder to it. Once you have got the knack you can get a good tinned finish. Clean the flux residue off afterwards with thinners and then wash with Swarfega or similar hand cleaner to get a bright finish on the tin (yes I know it sounds weird but try it).

There is a lot more detailed waffle and pictures of my experiments at Woody's Workshop.

I hope that helps someone somewhere to get a working result.

Steve Withnell.