Well as Not Done It Yet has not got back to us yet I'll enlighten you as to how the screwcutting method may work in theory.

Any fine pitch thread won't be any good as you will get a very long groove pattern that runs around the rod not across it so only good for pulling not turning.

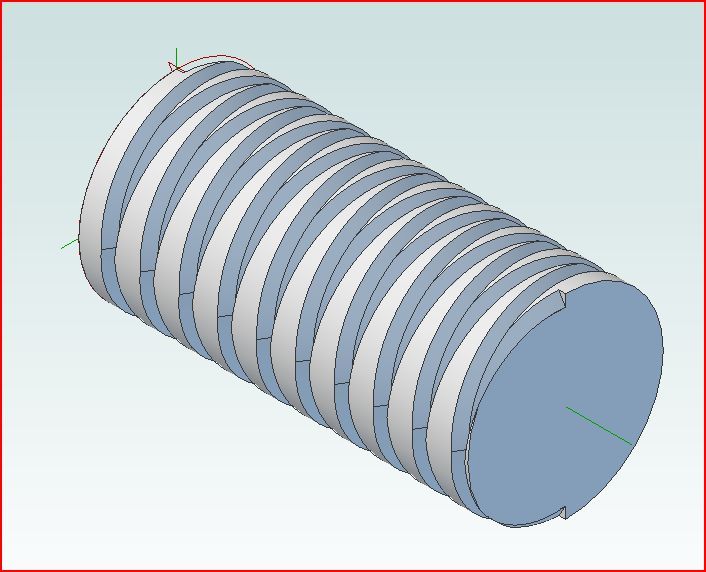

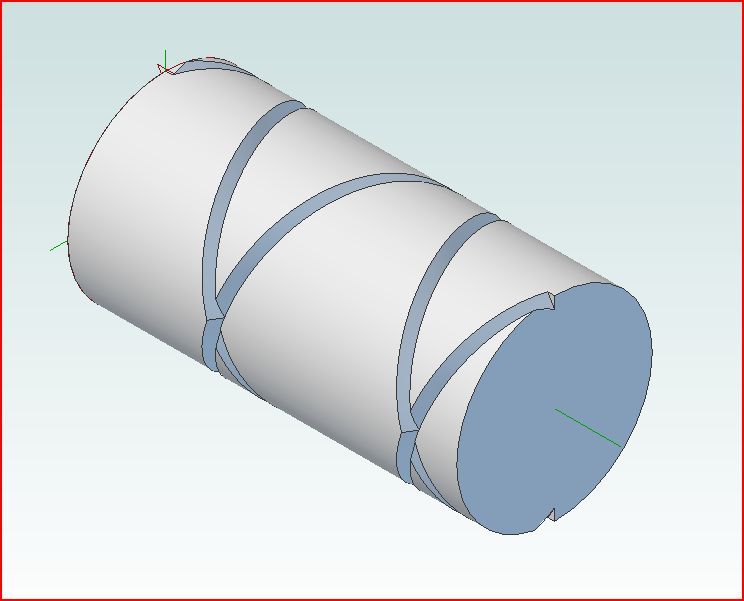

If you up the pitch then you start to get something more like an oil groove, pitch is 1D

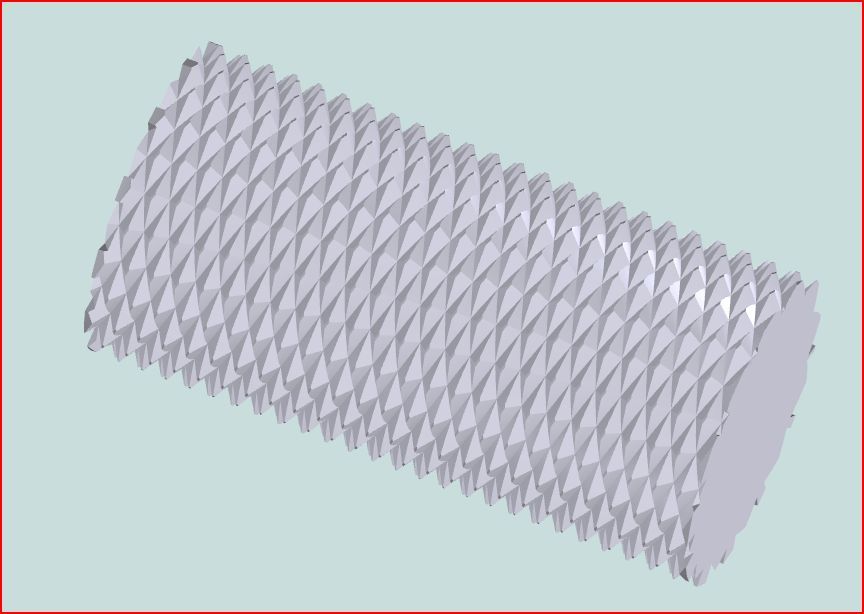

As I mentioned earlier and Steve also mentioned to get something like a knurl then a multi start thread is needed, this is the same pattern as above but with a 24 start

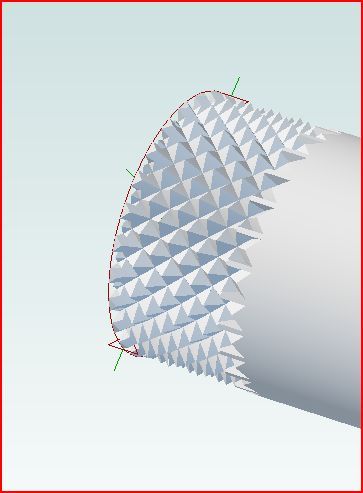

Still the diamonds are a bit long so playing about with teh figures to get the optimum diamond pattern the pitch of the "screw" needs to be Pi x D and the number of starts sufficient to make sure one Vee runs into the next and does not leave any flat tops to the diamonds (had to shorten the sample as it was taking the CAD a long time to do the cutting)

If you want to look at this finished knurl in more detail there is a 3D pdf here that allows the part to be moved about, zoomed into etc

The only problem with this is that unless you are trying to cut knurl a 1mm dia rod most lathes can't easily cut PiD pitches, the example above was 50mm dia so needed a 157mm pitch or about 0.17tpi. So the only real options for a screwcut method would be an electronic leadscrew, 4-axis CNC or as Michael hinted at above it could be done on an ornamental lathe.

J

Edited By JasonB on 30/09/2016 08:11:26

Ed Duffner.