Andrew said:

I understood that ER collets were originally designed for hold tooling, whereas 5C collets were intended for work holding. Of course there's nothing to stop you holding what you like in any variety of collet.

I would agree. There are not many machine with a native 5C spindle it appears. There are also very few 5C collet chucks to fit 'common' spindles – The geometry just does not fit. There are ISO40, etc, chucks, but they have the rear body to take the collet, but the 5C fastening mechanism remains a dilemma in such chucks. On the other hand there are hundreds on ER collet chucks in all spindle forms, MT, R8, ISO, straight shank, etc, etc. Which generally supports the idea of tool holding rather than work holding.

There has been comment on the comparative accuracies of ER/5C – I think it is not correct to generalise on this – if the effort is made to find ER collets of better than 'normal' runout, the same effort will find comparable performance in 5C collets.

When I purchased my EMCO lathe among the options I chose was a Camlock 5C chuck – this was supplied by EMCO and endorsed by them for accuracy, etc, but is actually a BISON 5C 'set-true' style chuck. Supplied with the chuck is a set of 53 collets – 1mm to 27mm in 0.5mm steps, and a set of imperial colletc from 1/16 to 1inch in 1/32inch steps.

The collets are very good – when the chuck is set up to run with zero TIR, a 25mm collet showed 0.0018mm TIR, a 15mm collet – 0.0017mm , a 10mm – 0.0015 and a 6mm collet – 0.0013mm – That is rather good I would say!

However, those measurments are with tool steel test bars, 'perfectly round and straight, and within 0.0001mm ground diametric tolerance.

I did the same measurements with a 10mm collet and a 3/8" (9.525mm) test bar of the same accuracy as the metric bars. The 3/8" bar would not comfortable fit the 9.5mm collet and the 10mm collet required 'closing down'

The TIR increased to between 0.008mm and 0.01mm and was not consistent each fastening. Fitting a 3/8" imperial collet and the runout was a consistent 0.0015mm to 0.0016mm.

I think the moral off the story is that a good 5C collet is very good when the held item is close to the collet native diameter. I think ER collets will battle to achieve similar accuracies under those conditions, but will achieve better accuracies with wider variance of held diameter..

I realise that TIR in the 0.001/0.004 mm are small, but while we are chasing numbers..

Also, I am a bit confused by Jo's statement:

I have never had any issues with using my 5C's they are excellent. The mounting of my 5C collet chuck has zero run out and I have Collets up to 1 1/4" (and28mm) in all the sizes that my drawings use. Whilst I have a ER32 holder I see no point in buying any collets to go with it as it is restricted to a much smaller maximum diameter than the 5C's.

I have measured up my 27mm ID 5C and I think at a huge push I could open it up to maybe 29mm. Can one actually get a 1-1/4" 5C collet?? Thats 31.75mm..

Anyway, I think the first view is correct – ER collets are more versatile and a lot easier to change size in the chuck!.

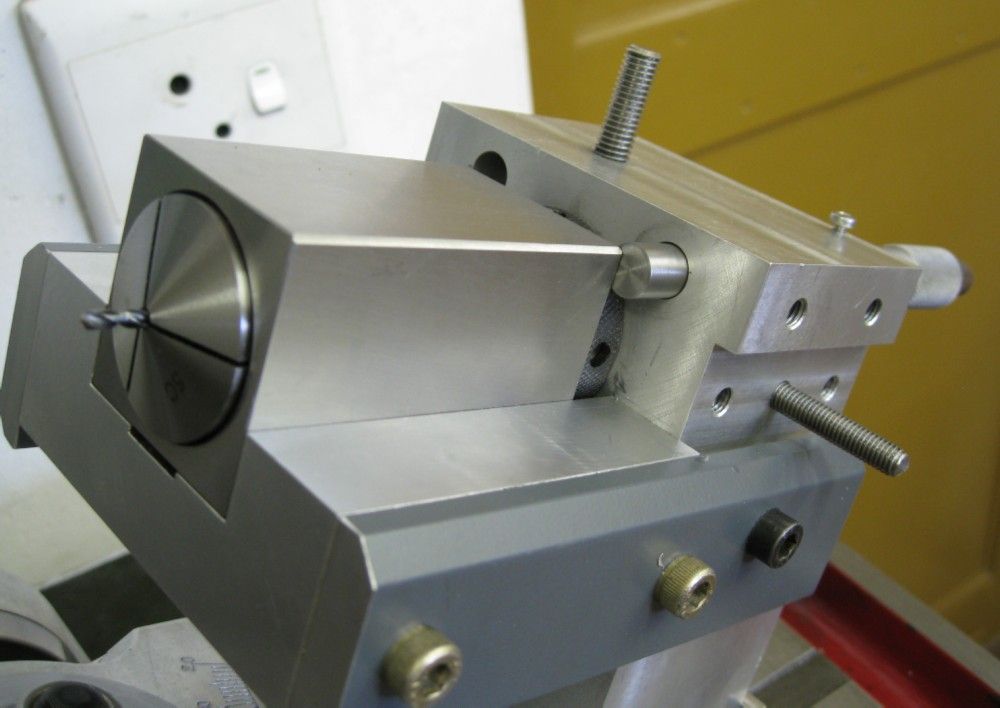

The one thing I did find – I made a 4 facet drill sharpening jig, at first using ER16 collets ( of good quality) but found very poor repeatability when setting the smaller ( sub 5mm) drill bits in the collet. The spiral cutting edge of the drill always seemed to hook in a collet slit and I was forever rotating the drill bit a fraction to 'miss' a slit, etc. I then tried ER20 collets and gave up – made a new jig using 5C collets and it works fine now..I suspect the length of the ER collet is a problem in this application.

Joe

Edited By Joseph Noci 1 on 17/02/2019 15:54:23

Edited By Joseph Noci 1 on 17/02/2019 15:56:36

CHARLES lipscombe.

.

.