Code here:

/*

Code by Kealan O'Carroll, April 2019

Encoder.h library by PaulStoffregen

http://www.pjrc.com/teensy/td_libs_Encoder.html

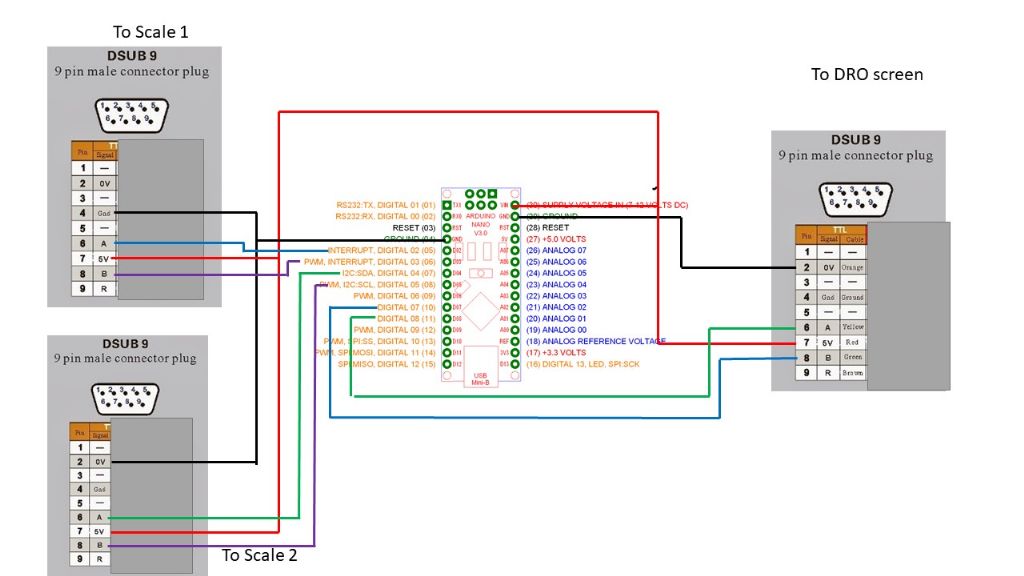

Code intended for an arduino nano with the following wiring:

Pins 2, 4 : Scale 1 inputs

Pins 3, 5 : Scale 2 inputs

Arduino Pins 7, 8 : Outputs to DRO A and B pins. (Pins 6 and 8 on a DSUB9 type plug)

*/

#define ENCODER_OPTIMIZE_INTERRUPTS

#include

Encoder scale1(4,2); //Wire first scale A & B quadrature lines to arduino Pins 2 and 4

Encoder scale2(5,3); //Wire second scale A & B quadrature lines to arduino Pins 3 and 5

//If either of the scales reads in the wrong direction, reverse the pin numbers above (e.g. (4,2) changes to (2,4)

long pos2 = 0;

long pos1 = 0;

long delt = 0;

long oldpos1 = 0;

long oldpos2 = 0;

long delt1 = 0;

long delt2 = 0;

bool outA = LOW;

bool outB = LOW;

void setup() {

DDRD = DDRD | B11000000;

DDRB = DDRB | B000001;

PORTD = B00000000; // sets digital pins all Low

PORTB = B00000000; // sets digital pins all Low

}

void loop() {

pos1 = scale1.read();

pos2 = scale2.read();

delt2 = pos2 – oldpos2;

delt1 = pos1 – oldpos1;

delt = delt2 – delt1;

while (delt > 0) {

if (outA == LOW && outB == LOW) { //if 8 is low and 7 is low

PORTD = B10000000; //push 7 high

PORTB = B000000; //leave 8 low

outB = HIGH;

delt–;

}

else if (outA == LOW && outB == HIGH) { //if 8 is low and 7 is high

PORTD = B10000000; //leave 7 high

PORTB = B000001; //Push 8 high

outA = HIGH;

delt–;

}

else if (outA == HIGH && outB == HIGH) { //if 8 is high and 7 is high

PORTD = B00000000; //push 7 low

PORTB = B000001; //Leave 8 high

outB = LOW;

delt–;

}

else if (outA == HIGH && outB == LOW) { //if 8 is HIGH and 7 is LOW;

PORTD = B00000000; //leave 7 LOW;

PORTB = B000000; //push 8 low

outA = LOW;

delt–;

}

}

while (delt < 0) {

if (outA == LOW && outB == LOW) { //if both are low,

PORTD = B00000000; //leave 7 low;

PORTB = B000001; //Push 8 high

outA = HIGH;

delt++;

}

else if (outA == LOW && outB == HIGH) { //if 8 is low and 7 is high;

PORTD = B00000000; //push 7 low

PORTB = B000000; //Leave 8 LOW

outB = LOW;

delt++;

}

else if (outA == HIGH && outB == LOW) { //if 8 is high and 7 is low;

PORTD = B10000000; //push 7 high

PORTB = B000001; //Leave 8 HIGH

outB = HIGH;

delt++;

}

else if (outA == HIGH && outB == HIGH) { //if 8 is high and 7 is high;

PORTD = B10000000; //leave 7 high;

PORTB = B000000; //Push 8 LOW

outA = LOW;

delt++;

}

}

oldpos1 = pos1;

oldpos2 = pos2;

}

Edited By Kealan O’Carroll on 26/04/2019 17:44:17

duncan webster 1.

contradict each other in a minor way.

contradict each other in a minor way.