Firstly, many, many thanks for all the comments and help.

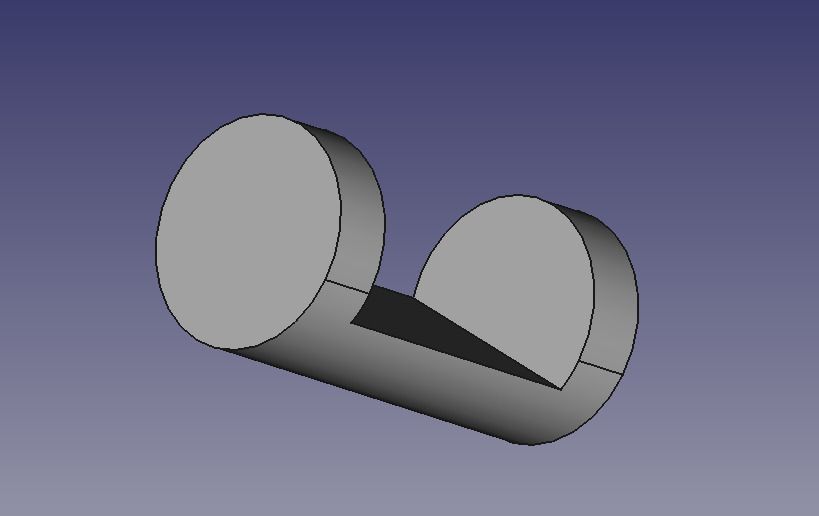

For clarification, at the risk of being boring, what I'm trying to make is a pivot to sit between the forks of a vintage Austin Seven brake lever. The slot is necessary to accommodate a rod that links the brake pedal to the lever without putting any sideways load on the connection (rod).

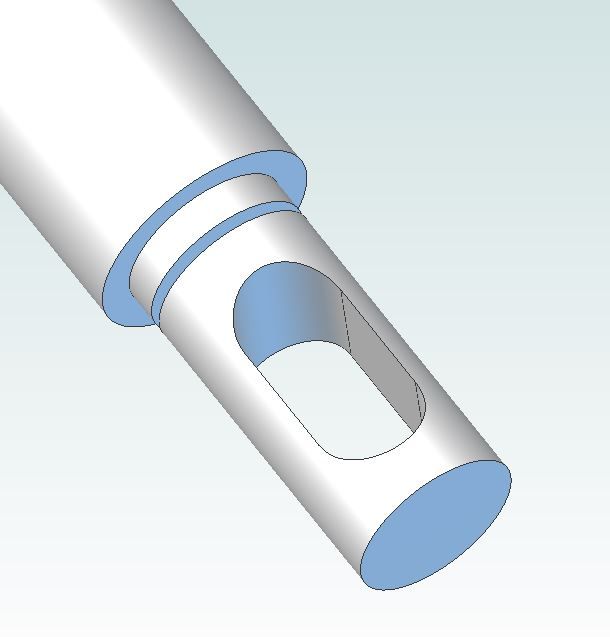

To make the pivot I'm using a surplus Austin Seven gearbox mainshaft which is a nice bit of 'stuff' and because the gears would have been keyed to it, is not in itself hard. Its about eight inches long and 19 mm in diameter. and I turned it down to 14mm which is the only really critical dimension (hole in fork).

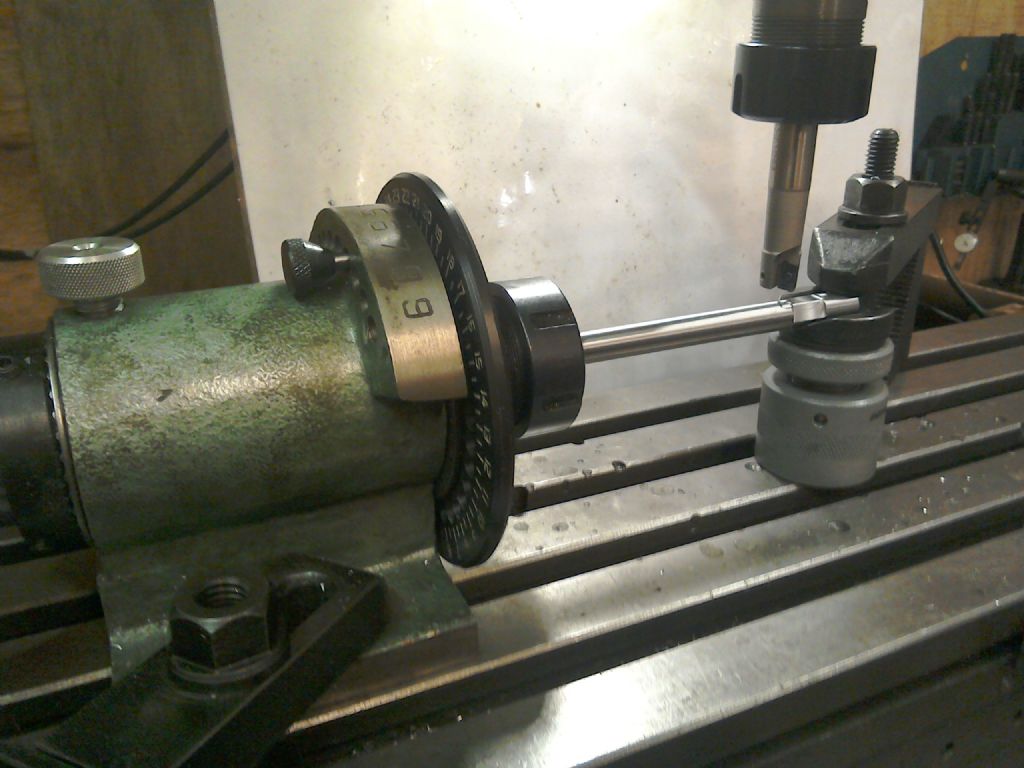

I am holding it in a collet block with an ER32 collet in a Vertex 4 inch vice on a Warco Economy mill. I have about 35 mm protruding out of the collet and for the later/heavier cuts I supported the overhanging end in a vee-block. Prior to that the collet block tended to tilt downwards.

Thus, I think overall rigidity is an issue.

I centred the spindle over the stock with one of those simple 'swinging vee' gadgets, scribed a line along the axis; centre drilled at both ends 4mm + 4.5 mm from the true end and from the intended cut off point (27 mm overall). Four millimetres because that's how much solid metal I want to insert on each side of the fork and 4.5mm because that is half the diameter of the width I want the slot. The rod is the diameter of a 5/16 BSF thread. (7.9mm)

I drilled on the centre drill indents at 6mm, 8 mm, 8.5 and 9 mm. When I now say mess I mean the 9 mm wandered off and chewed the sides where there's not much lee-way (as you point out) – 2.5mm. That's why I corrected with an 8 and 8.5 and why I think rigidity is an issue.

I tried to take out the remaining metal between the two holes with an 8mm slot drill and that was a mess too. In fact it wouldn't do it! Stalled the mill. Resorted to a file.

This is another bit I don't understand! I know that the difference between a slot drill and an end mill is that , because of the way the teeth on a slot drill are formed, they can 'plunge' whereas end mills' capacity to 'plunge' is minimal. Yet, my slot drills have a marked reluctance to 'plunge. Do you….drill a hole first, insert the slot drill part way – say for the sake of argument – to a depth of 2mm, then advance it the length of the slot – say 20 mm, come back, go down another 2mm and advance and so on until you are at depth or do you advance (plunge) the slot drill the full depth, as you might a conventional drill, then advance it along the slot cutting all the way in one go?

Good news is, the pivot piece, rough and unsatisfactory from a machining point of view though it is, works like a dream.

Thanks again.

—

SillyOldDuffer.