Thanks for all the knowledge and interest – various bits of feedback as far as I know them:

– relief – I didn't make the current tap or guide (I did make the cutter and box) but in these things the cutter depth is adjusted so the screw runs smooth but not sloppy (in the wood nut). I suppoose this has the effect of giving some axial clearance, but it's a bit more crude – pretty much everything is as we are dealing with wood, grain, atmos movement etc.

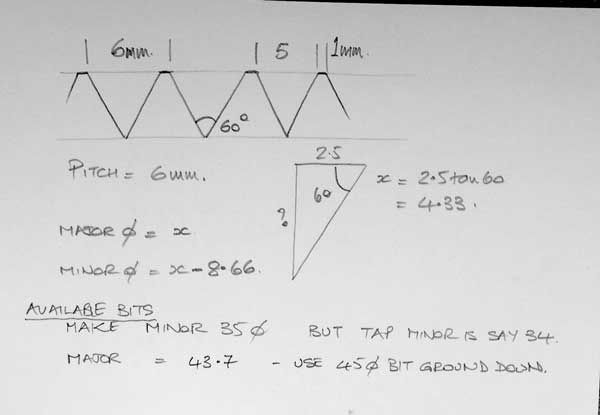

– the angle is definitely 60 degrees, pic is not very good, but I know from making the cutter

– my sums were rubbish, the current 4tpi uses a 35mm bit for female blank, and a 41mm approx dowel that the screw is cut from. I need to check the tpi, do we talk points or whole teeth?

– optimal tpi – from playing with many different wood screws for vices, I am sure on this one that my 4tpi is a tads steep, 6 is too fine, but best guess would be I'd like about 4.5 – 4.8.

– bad drawing, the thread is cut on axis, the taper creates progressive flats towards the leading end.

– rads and flats – my guess would be make the tap to apex points on the thread, then nick the tops off anyhow. Make the die / thread box so a small flat exists between threads (maybe a mm) – the tip of the screw has no strength and does no useful work.

I promise I will do another drawing soon as I get a minute…!!

Hopper.

![2016-05-05 09_58_55-autocad 2010 - [drawing1.dwg].jpg 2016-05-05 09_58_55-autocad 2010 - [drawing1.dwg].jpg](/wp-content/uploads/sites/4/images/member_albums/150952/672005.jpg)