Posted by JOHN BURNELL 1 on 10/09/2017 21:41:26:

Is there any other machine with a very similar tail stock arangment ? as i said i have read in older threads that the ml 7 will fit, all is not lost as i can still use it for centering etc and in ref to drilling this is going to be my difficulty but as i only need to drill to re pivot my clock repairs i will aft to find a way to move the tailstock along, im begining to think the centre going through the tailstock something was wrong as the face plate does not fit either it is supposed to be m14x1.5 but on measuring the thread on the plate its 12mm but to be honest i am still happy with the unit i will aft to get my thinking cap on just need some ideas, i will get in touch with cowells but dont fancy paying a few hundred pound when im only using the lathe for pivot polishing etc,

but to be honest i am still happy with the unit i will aft to get my thinking cap on just need some ideas, i will get in touch with cowells but dont fancy paying a few hundred pound when im only using the lathe for pivot polishing etc,

regards john

.

John,

I think you have been finding some dodgy information, if you've read that an ML7 tailstock will fit a Cowells.

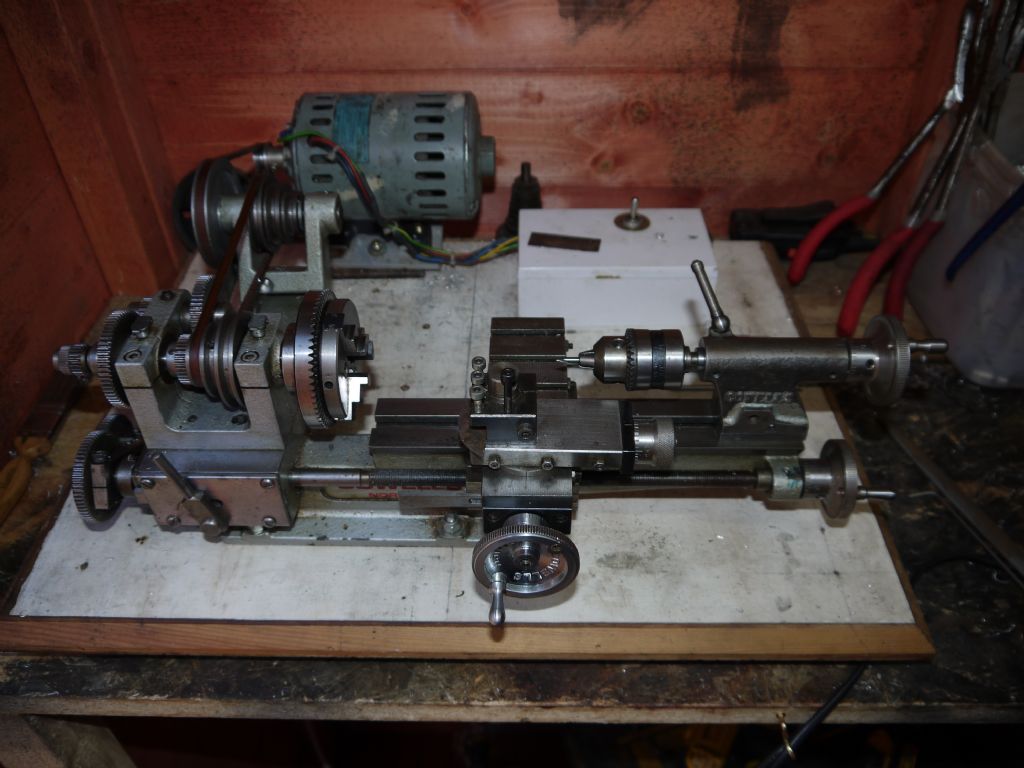

I posted a link to "watchmaking.weebly" on your other thread … With the greatest respect; I think you need to check exactly what lathe you have. Look at his pages about the 90 CW http://watchmaking.weebly.com/lathe-maintenance.html and also Cowells site.

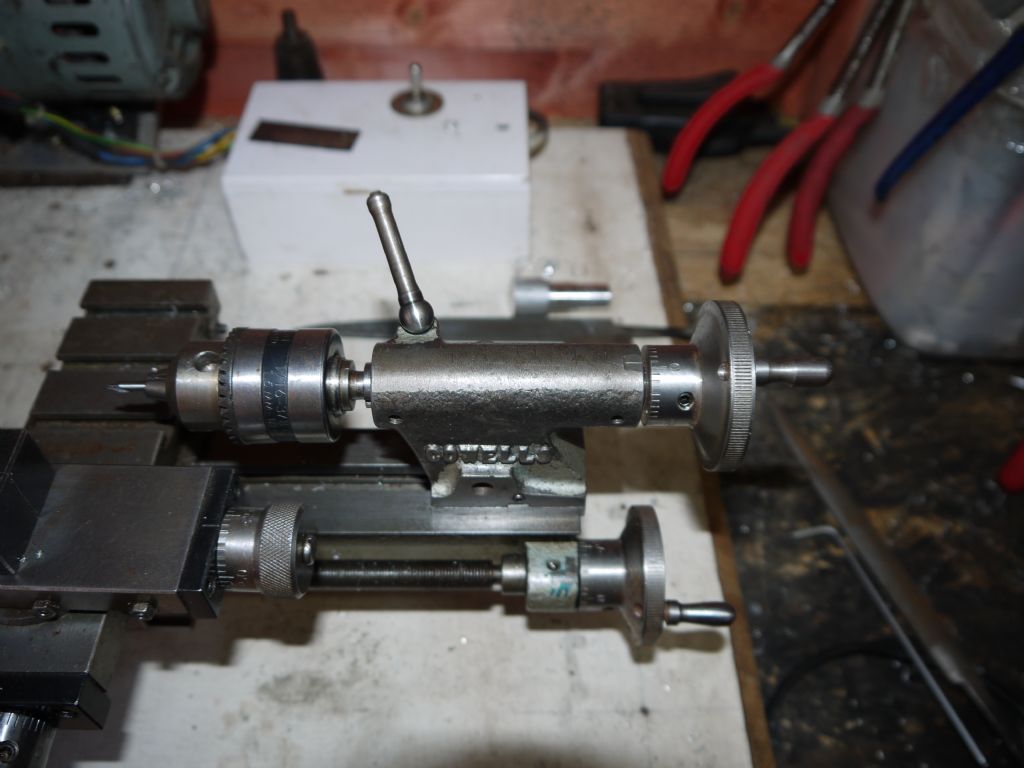

Rearding the faceplate: The early Cowells had a different headstock spindle to the recent ones, and of course the 'Watchmaker' version has another variant.

MichaelG.

.

For info. : This is the early headstock spindle:

Edited By Michael Gilligan on 10/09/2017 22:04:44

Michael Gilligan.

Michael Gilligan.