On this question of whether or not the air/condensate pump creates the vacuum or not..

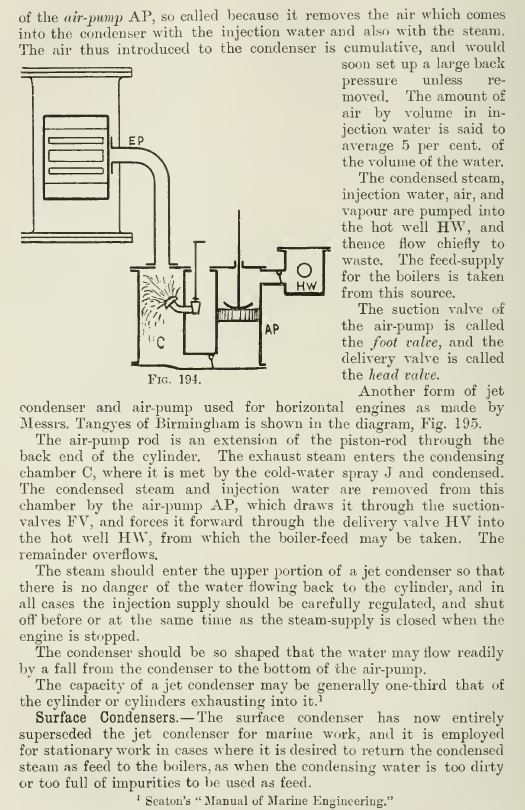

My experience is that you won't see any vacuum until the pump is working. At the beginning of the process, the condenser will be full of air, which is rather hard to condense, so until that has been pumped out you won't see any vacuum. Actually of course steam from the warm up might well have displaced a lot of the air, but if the cooling tubes are full of cold water that steam will condense and the condenser is liable to be flooded with condensate.

However, the point that someone no doubt was trying to make way back in history, is that the whole process would not work if steam/water did not have the lovely property that the volume of the water is about 1600 times less than the volume of the corresponding steam. So to maintain the vacuum it is only necessary to pump out a relatively small volume of water, plus of course any unwanted air that has made its way in.

The same thing is also an advantage on the feed pump side. Compare the relative size of the feedpumps to the main engine, then compare the size of the compressor on a jet engine to the turbine. Sadly for steam we also need a relatively large boiler to heat the working fluid, much bigger than the combustion cans on a gas turbine. Perhaps a better comparison is the much larger size a typical hot air engine needs to generate a similar power to a steam engine

Practically, on my own plant on "Dancer", it is necessary to open the vacuum breaker for a bit on starting out. This allows starting out without pressurising the condenser and allows the circulating pump(driven by the main engine) to start the flow of cooling water. After a short time, the cloud of steam over the side from the vacuum breaker diminishes greatly and condensate starts to be returned to the hot well. At that point, the vacuum breaker can be closed and the air/water pump starts pulling down the vacuum. When all is well it takes maybe 10 to 20 seconds for the vacuum gauge to climb around the scale.

Running on salt water was relatively common in the early days of marine steam, even into the 1850's.. It is very wasteful since the boiler tends to get loaded up with solids so has to be blown down frequently or even continuously, and the salt content raises the temperature required to boil the water. A boiler full of salt water is also very prone to priming.

All this is of course pretty irrelevant to a model, where efficiency is not a great concern, but it is kind of satisfying to do things properly even if it doesn't matter. Condensing the exhaust, even if you don't care about the vacuum, will reduce the cloud of steam that would otherwise result, which might make it nicer to run on steam for a public display.

My own favourite reference would be "The Efficient Use of Steam" by Lyle Watson.

John

GordonH.