Quick update

I no longer have access to a milling machine at home, so I enlisted the help of Phil to machine me a 304 stainless steel t-nut for the top slide so I can mount the new tool post.

I did initially go to the university engineering workshop to ask for their help but they were not interested as it was hard steel and they wouldn't let me in to do it either.

So, Phil helped me out greatly. Big thanks to Phil for all of his help

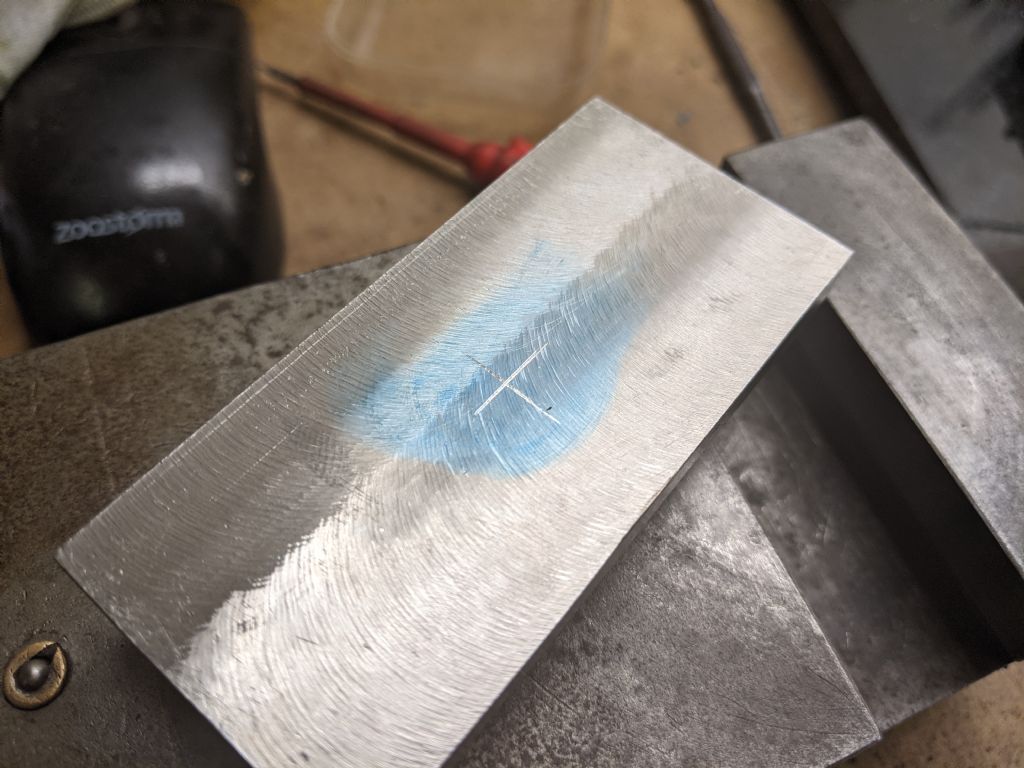

304 is a pretty tough steel, especially for an unexperienced person like me, but we made the best of it. We started using a face mill to make the block square, then we took it to size.

Cleaning it up gave quite a nice finish. Although I did get some chatter later on.

The end dimension had 10mm to come off, so it was much quicker to cut it off with Phils very nice mechanical hacksaw.

Some faces had 1mm or two to come off, so It took me quite a while when taking 0.2mm cuts. The steel got some very nasty burrs too, if that's the right word when they're so large! I presume that'd due to the steel being hard and due to my milling direction.

Then I cautiously moved onto using a hss endmill to cut in the slots. After 30 passes of 0.2mm cuts we has a 6mm recess for one side, then the other side was done.

The hss worked surprisingly well. I had bought a carbide endmill to use, but it wouldn't fit in any of Phils chucks.

Now to size, it was time to deburr and drill the hole

The drill size was stepped up very gradually as the metal is tough and we didn't want to work harden it at all.

Then we got the 5/8ths sae tap to go in the hole and lead it in using the drill press to ensure it was square

The tapping was slow but worked well with lots of lubrication. But it all went smoothly from that point. A very nice fit for a novice like me! Room for improvement in the future, but I'm happy.

Tool post fitted. I can't decide if I'll turn down the extra thread on the end. It doesn't add any value, but who knows if I'll need it in the future.

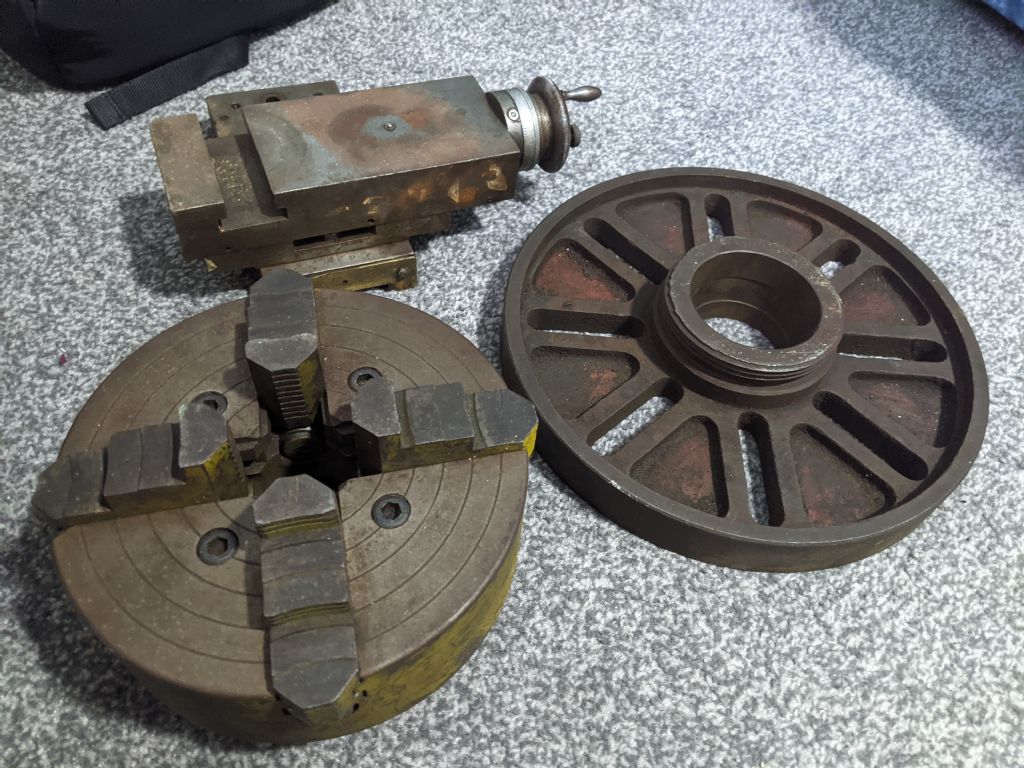

Next step is to get back home from university and disassembly everything to clean and get parts from both top slides to pick the best of each. Then onto some turning!

Thanks again to Phil for his time and help, if you want to see more there will be some footage of the milling on his Youtube channel.

Phil Whitley.