Posted by Phil Whitley on 16/12/2019 10:43:01:

Thanks Mal, thats interesting, possibly shows up how they fail when they do, although you would expect it to deliver its rated output reliably, but then again, it is probably made in Italy, like much of the machine mart electricals, which means some is good, and some not. I have a Clarke single phase mig from machine mart, and made in Italy, bought in the eighties, and still welding well after much use and abuse, it has had a couple of repairs, but I certainly have no complaints, and I am working on a SIP italian welder /battery charger, which is still going strong, and is suprisingly well built too!

Just a thought, did it rattle like this from new, or did it start rattling when it began going faulty?

Phil

Edited By Phil Whitley on 16/12/2019 10:47:00

I wouldn't assume the PC40 is necessarily faulty, or that replacing it with with a new PC60 will result in success!

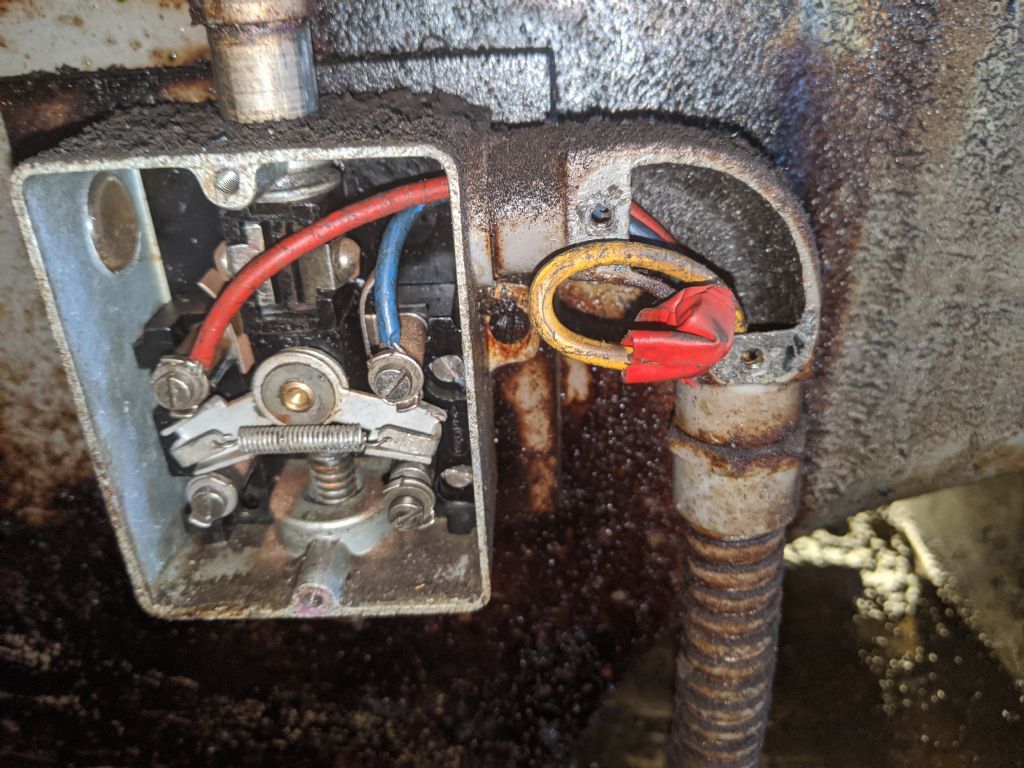

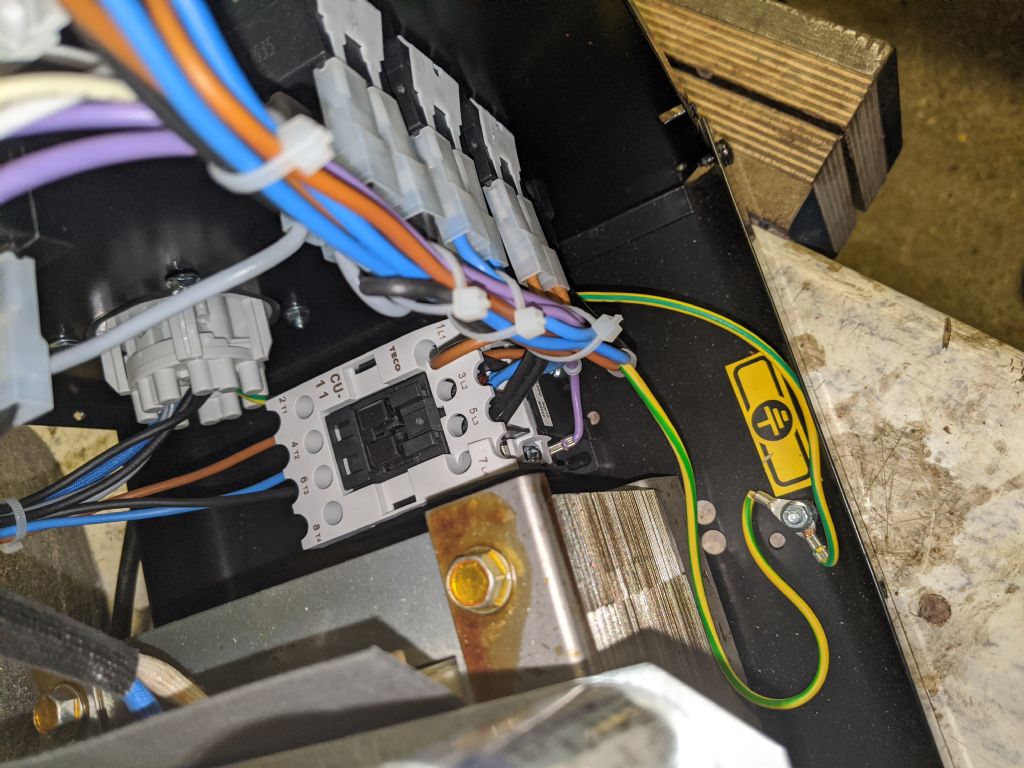

Richard mentioned his lathe dates to 1955 and I'd have guessed earlier. The electrics appear to be original, 64 years old, and the lathe has not been kept dry. Furthermore someone has messed with the wiring, presumably in an attempt to get it going. To that I'd add the possibility that the drive train is gummed with old oil, or that new oil is stiff because of the cold weather. Maybe this adds up to more than the PC40 can cope with.

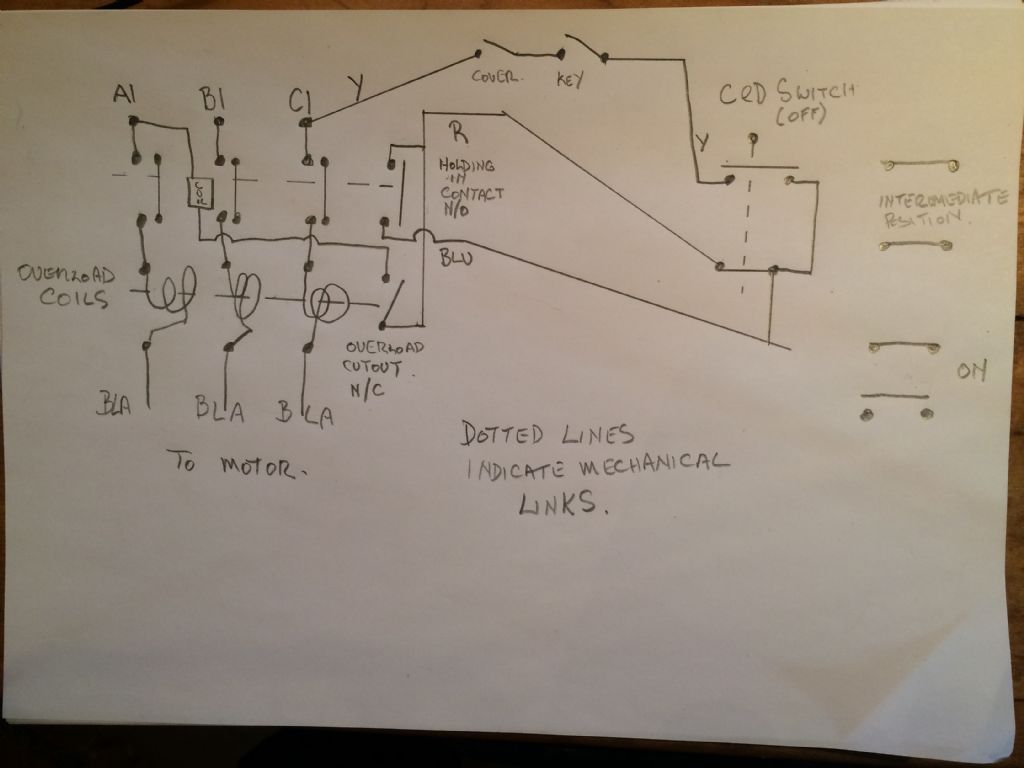

The other issue is the sort of device the PC40 is – static converters have distinct limitations! This type of converter isn't recommended for heavy or intermittent loads. From the manual:

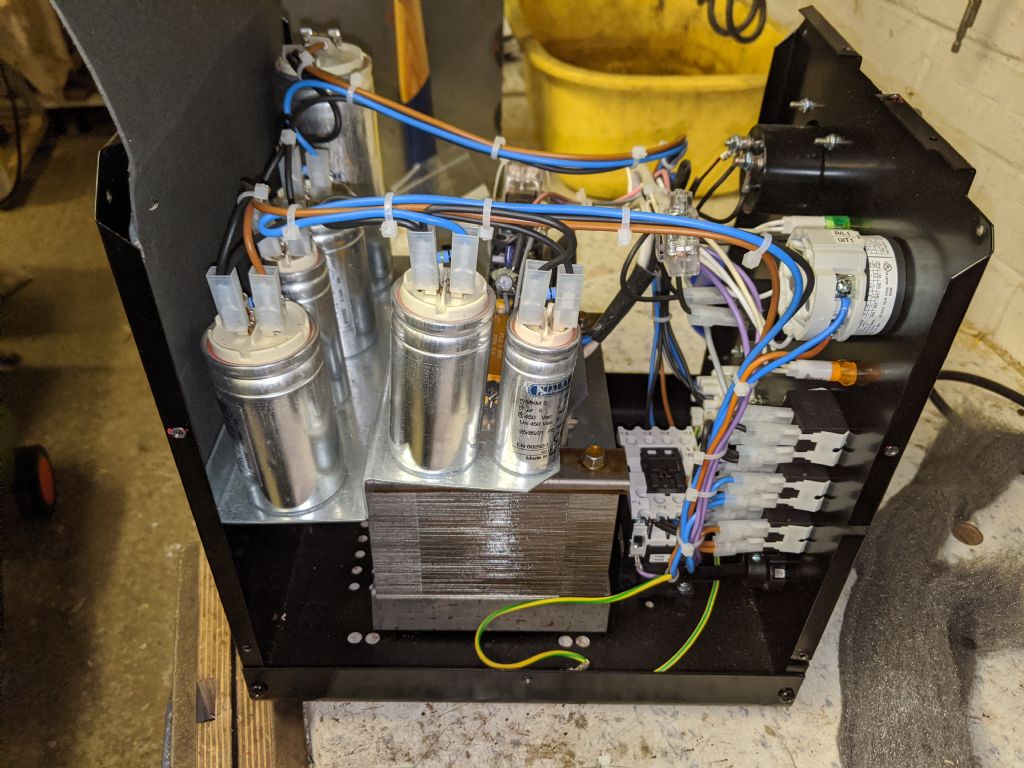

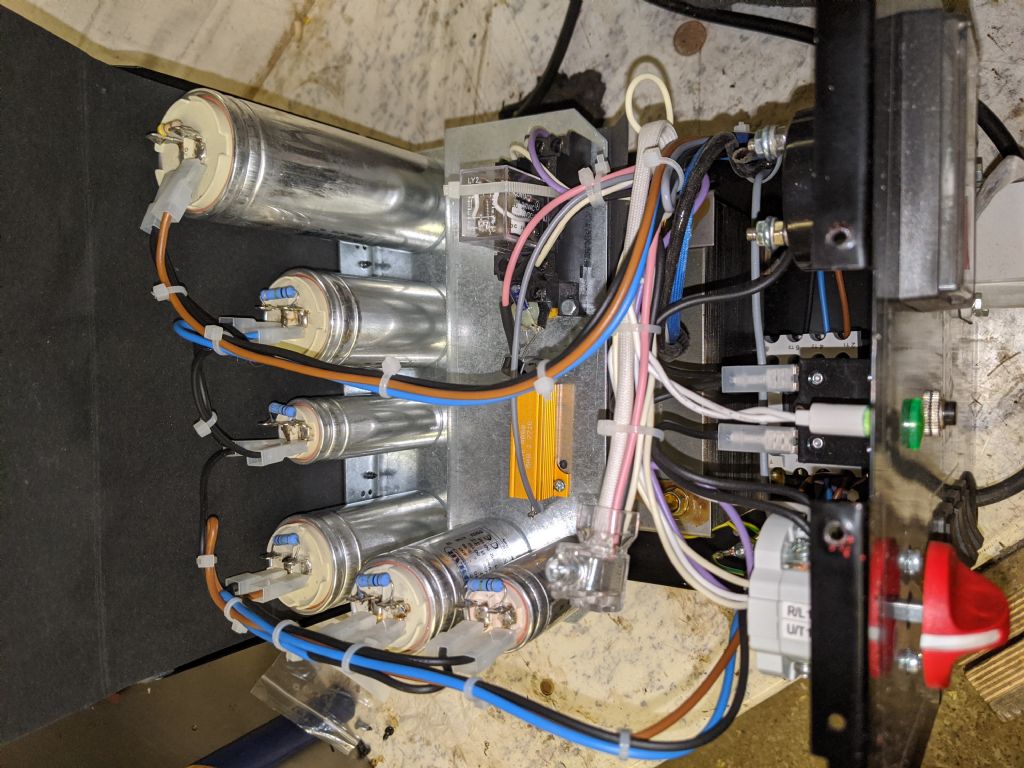

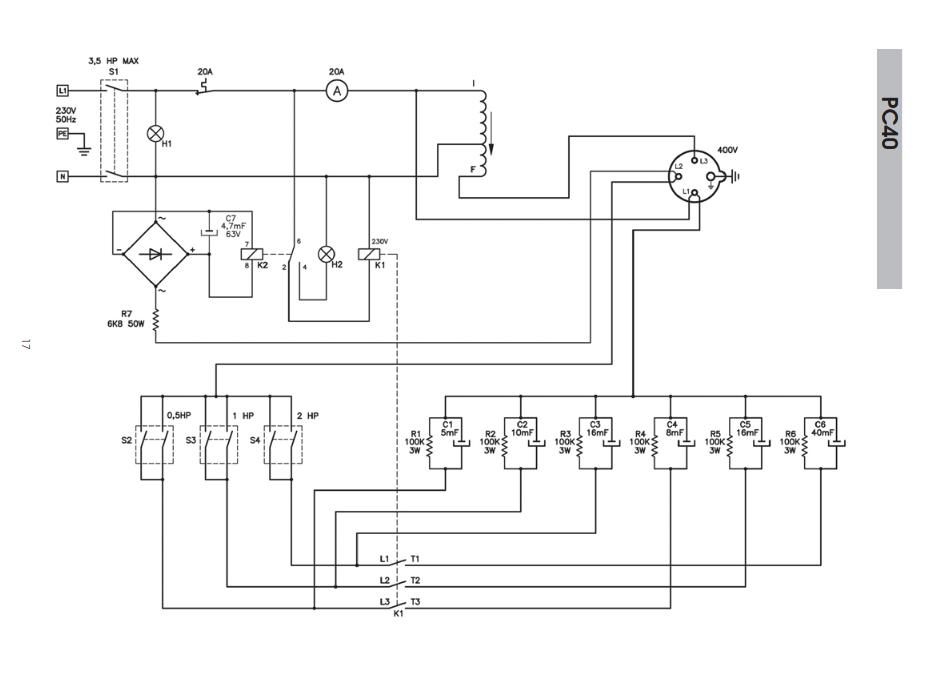

The circuit shows the device briefly bodges an approximation of 3-phase with capacitors as a way of starting the motor. It doesn't output continuous 3-phase like a rotary converter or a VFD. The motor cannot develop full power.

Although the necessary capacitance is broadly related to the motor's output power, it's not that simple. The switches marked 1HP, 2HP and 3HP don't set power output, rather they add or subtract capacitors as necessary to match the motor to get enough phase-shift on the 3rd winding to start the motor. Page 8 of the manual shows 7 switch combinations for 0.5 to 3.5HP; the user should experiment for best starting.

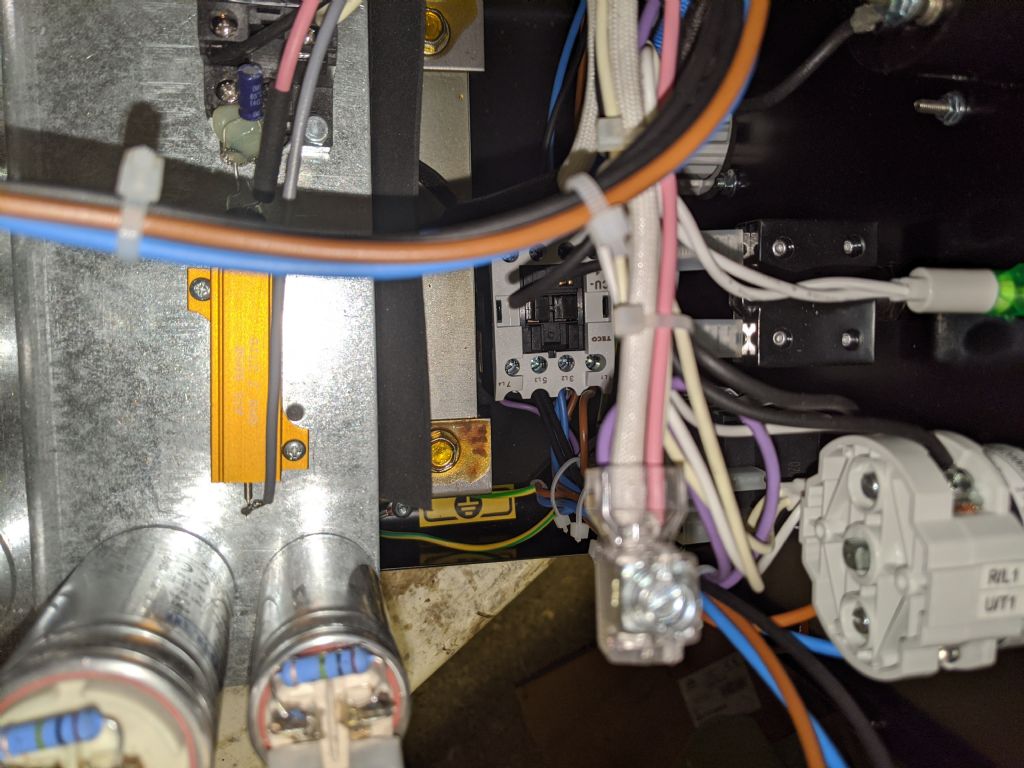

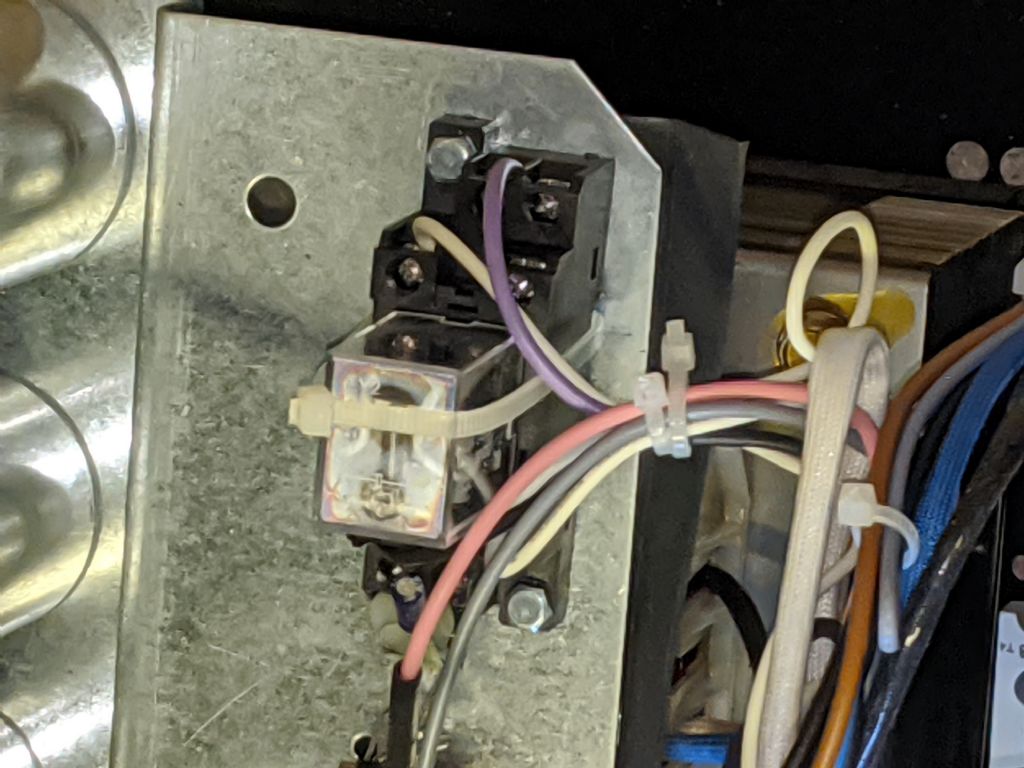

Once the motor is rotating, I believe relay K1 disconnects the capacitors and leaves the motor running on two windings only. This considerably reduces the power output of the motor compared with what it would do with real 3-phase. I suggest the relay chatter is due to the PC40 thinking the motor has started and then detecting the motor is stalling, thus kicking again by reconnecting the capacitors. It's hovering on the brink of a successful start.

Note that the capacitors are only used during starting. Using this circuit for frequent stop-start work, as on a lathe or mill will shorten their working lives.

As the device is distinctly limited, they aren't suitable for all motors, or operating style. The manual says:

Thank you for purchasing this CLARKE Single to 3 Phase Converter. i.e. to run 3-phase asynchronous motors ONLY, from a 230V single phase supply.Please note that this device, because of its characteristics is for use primarily with constantly running motors. It is not desirable for use with stop start operations.

and

For some applications of small motors, or motors of unusual magnetic characteristics, it may be necessary to provide a pilot motor to obtain a balance of phases. Generally the pilot motor should be a 2 pole (2800 rpm) motor and as a general guide should be at least twice as big as the motor to be driven.

Why is the motor stalling? The PC40 must have done it's job as a starter, but maybe its autotransformer can't deliver enough amps to keep the motor turning. (A PC60 has a bigger transformer.) Or equally likely, it's because the lathe is stiff! Could be the motor would run OK on a warm day with clean bearings, but December in a clogged state is just too much. (Measuring my WM280 in a different context showed just turning its spindle, gears and leadscrew takes about 200W)

Longer term, I think a VFD would be a better solution than a PC60,. Apart from a VFD producing genuine 3-phase and getting the best out of the motor, a PC60 needs a 32A single phase supply!

Dave

Phil Whitley.