My friend says he has some goggles so hopefully he will be able to find them for next week or whenever it is.

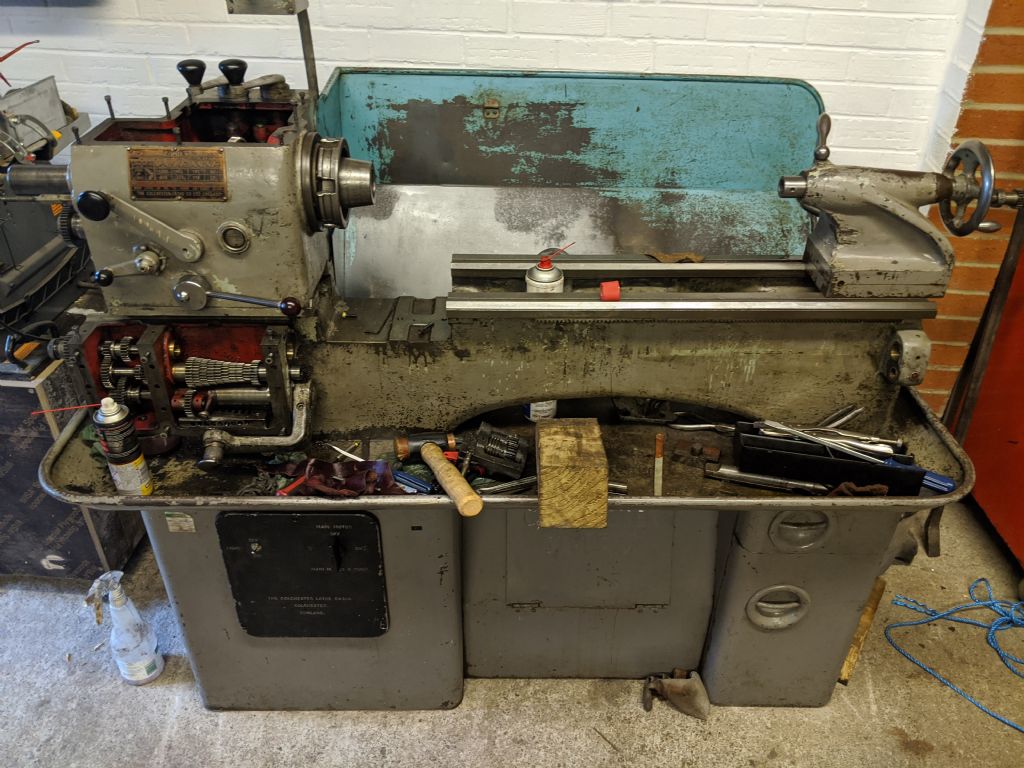

A little bit of progress today, although now I'm stuck

Getting the leadscrew out proved a bit more difficult. There's a step that Herman missed in his post so I didn't think to undo a screw and it left me just scratching my head for a while. Until I'd had a cup of tea and thought about it properly

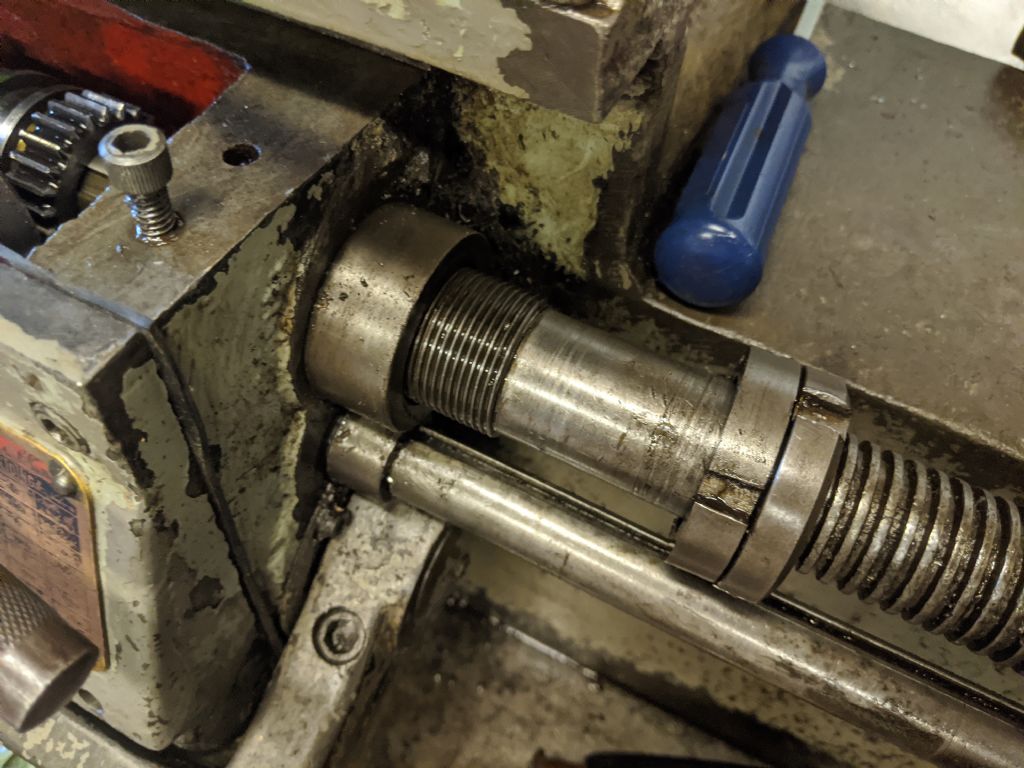

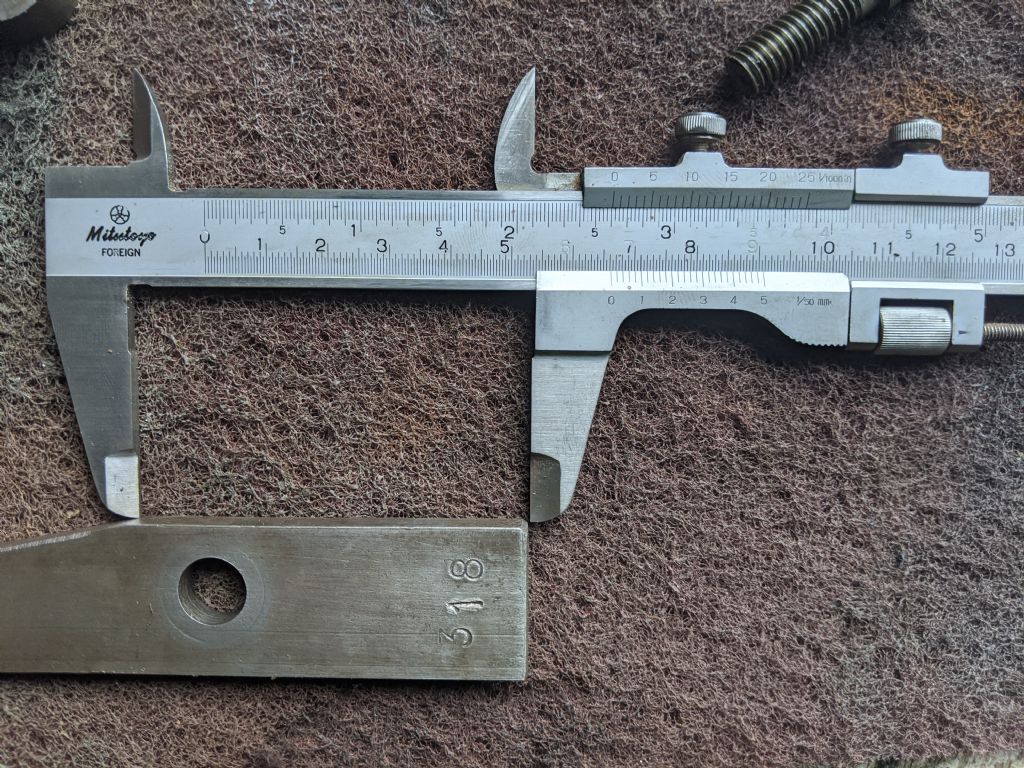

So the first step was to undo the collars. They came off quite easily, although I will clean the thread out and make sure they fit better when they go back on, as they were stiff in certain places and slacker in others.

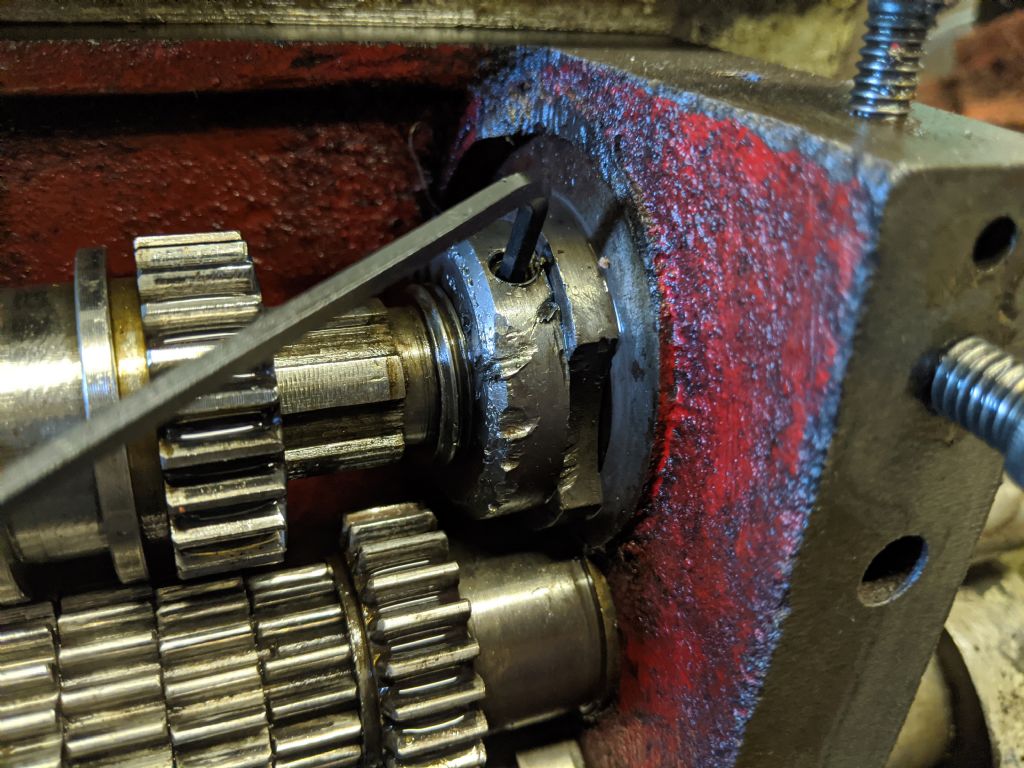

Then my inner collar had a set screw instead of having slots like Hermans. I put a bolt in and used that to turn it a bit. The marks were already on the collar, so someone must have been in here before me. That's not to say I didn't leave some more…

Nothing I can't clean up before reassembly

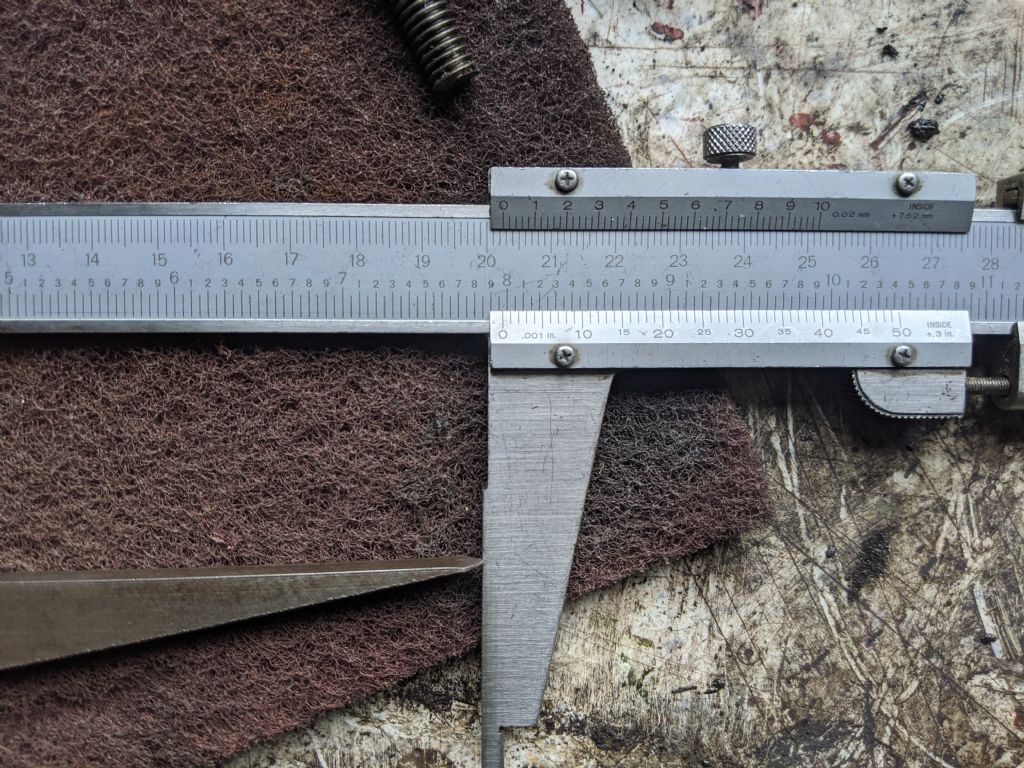

At that point I went to the end and looked at the set screws down there. Thinking about this further, the grub screw only holds in the bushing, so shouldn't effect the leadscrews removal.

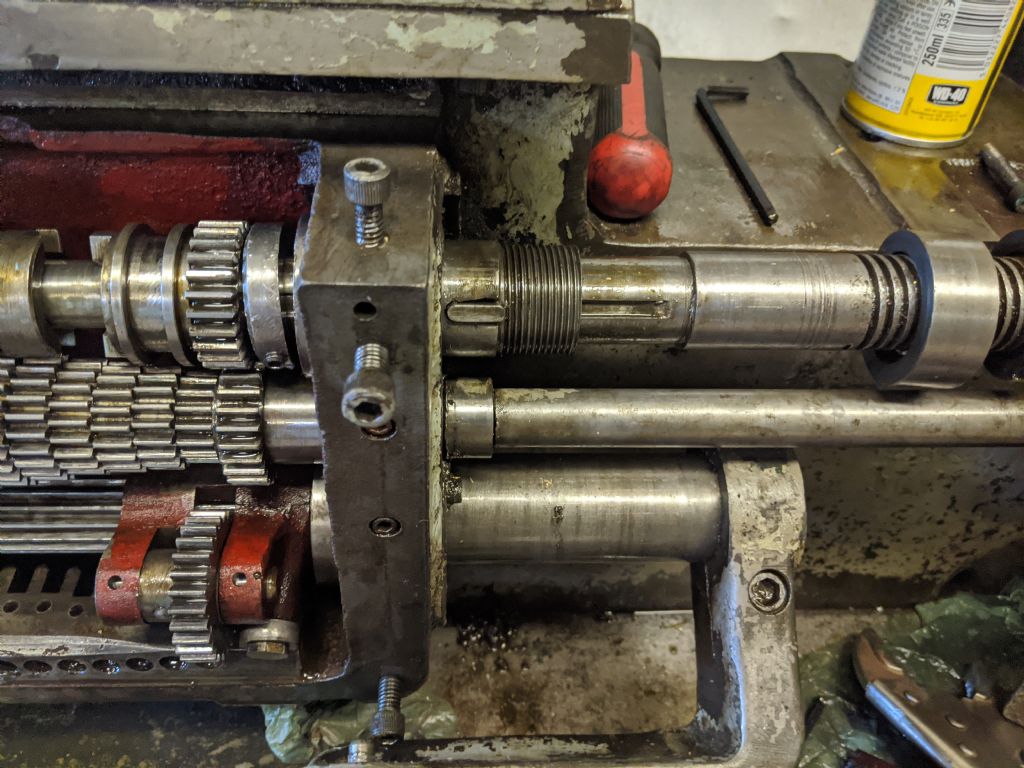

While I was down there I also removed the grub screws from the collars on the feed shaft. But, the outer one's set screw is stuck and the Allen key just spins. No good, but at least its the outside one rather than the inside one. The inside one came loose very easily

At that point I thought the leadscrew should have been free to move along a bit, but it would not move far. So I took a look at the shaft and thought that it was a bit dirty so I cleaned all the muck off. I plan to sand down the leadscrew for 370 hours to remove all the imperfections and then polish it until I can hang it in the bathroom and use it as a very small cylindrical mirror, as that's how all functional lathe parts should look! Bling must make it work better!

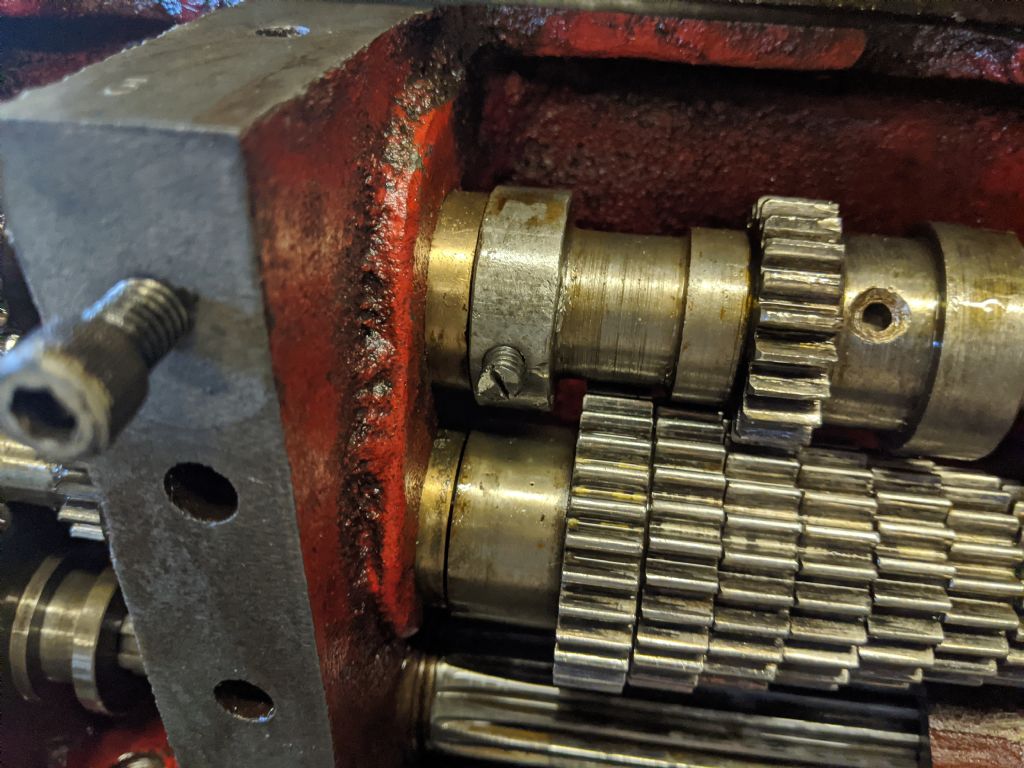

Anyway, joking aside, then I sat around for a while and had a break. I came back with a fresh perspective and tried to remove the screw in this gear first, resulting in the leadscrew coming out a bit, then i could unscrew the collar some more, then get the leadscrew out further and so on until the leadscrew was free!

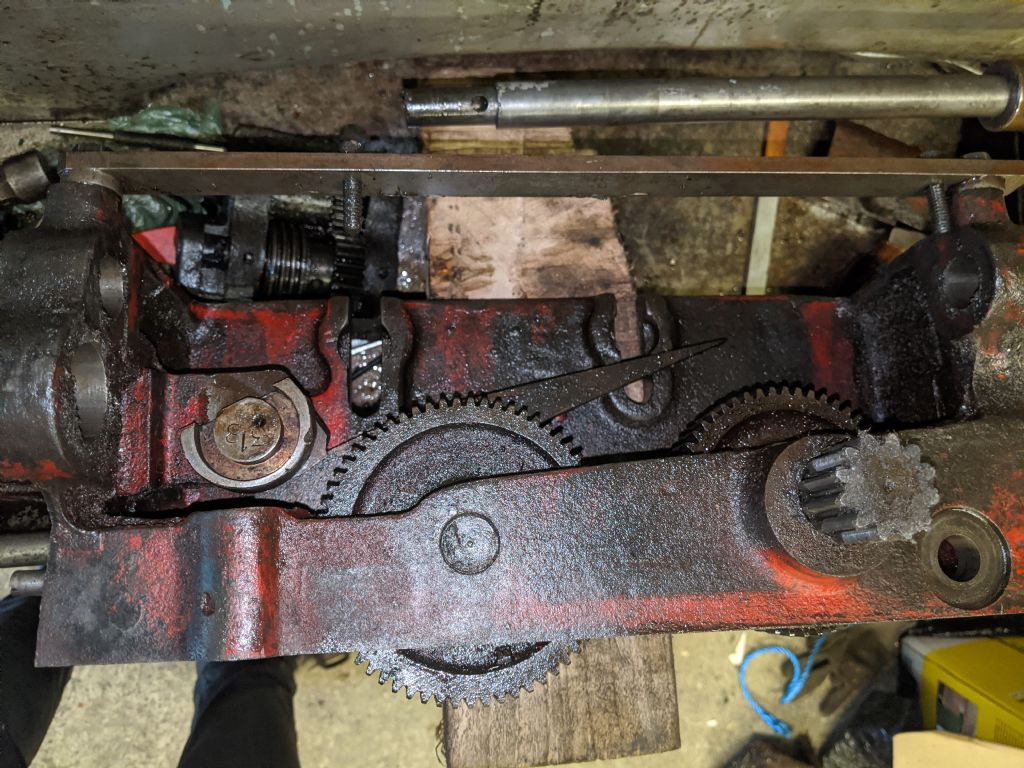

Having the leadscrew out allowed the half nut to drop out, since the shaft is shorter and broken. The feed shaft needs to come out to allow it to be reinstalled once fixed. The break lines up perfectly when its aligned

Definitely worthwhile taking it out, especially for a clean. Probably 2mm thick gunk at the bottom. Not good

Anyway so now I'm stuck. I cannot get the feed shaft out. It should just slide out. It will move about 2mm and then it just stops. It definitely feels spring-loaded like Hermans should have been, but I gave it a very good tug and I can't get it to budge. Any ideas? I've checked for pins and things like the later models have, but I haven't found anything.

However, I did find something coincidental. At the back of the gearbox, since the gears have been removed, I can now see that it says 5 AUG. Which may refer to the 5th of august, which happens to be my birthday. It probably doesn't mean that really, I can't imagine they'd date all their parts like that. In which case, what does the 5 AUG mean?

Edited By Richard Kirkman 1 on 03/08/2020 20:18:04

Phil Whitley.