Posted by Herman van der Merwe on 28/07/2020 19:26:43:

Nice gift to yourself! I was looking last night as to what the cross-slide and screw cost on the Bay. Sit before you look at the price …

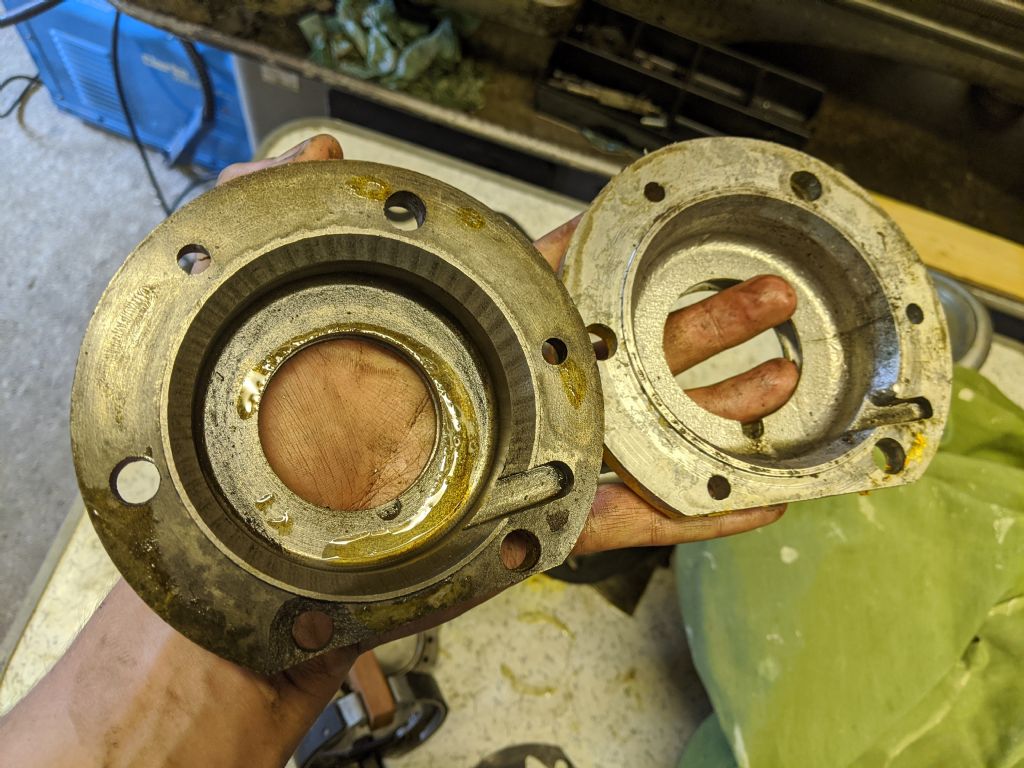

I actually plan on keeping my original cross slide parts. I don't think these ones would fit mine anyway. So once again, I'll hopefully find someone who needs them.

Lots more progress made this evening.

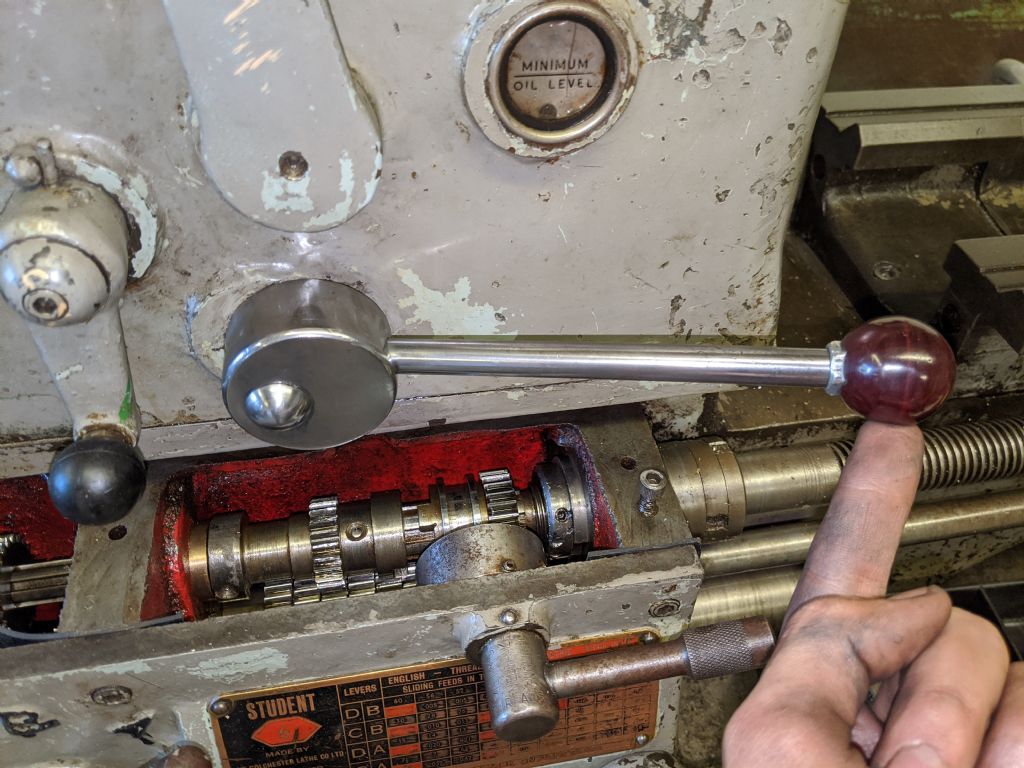

Firstly I looked at the on off levers. They are almost identical. Except the new one isn't worn! So it will be perfect. but only if the ball comes off the original. I don't like the brighter red one…

Then I got to work on the apron wheel. I took it to the wire wheel and polished it up a bit. Not its final finish, but close enough for a quick play today

Then came a very important task. The splines were full of crud and rust and all sorts, so I spent an hour filling down the inside of the wheel so it now pushed on and off with a little bit of force. Not too tight, not too loose.

It looks fantastic, I'm very pleased. However, It most definitely needs a lick of paint(more so than the rest of the lathe)

Then I had a look at the backsplash. This part seems to go on here? But I don't know what It's for?

Then I had a little mock up of where the backsplash attaches. It looks perfect. From what I remember it's not the same shape as Hermans and Phils, but it has a space for the two holes in the back of the headstock to pass through. Which I think is for the taper attachment? I'll have a go at fitting this after I've given it a clean tomorrow.

I thought I'd take the wheel off the tailstock while I was cleaning things. So I removed all the paint from the areas that shouldn't have been painted; They both still need fully stripping and painting nicely

Meanwhile, it's looking better

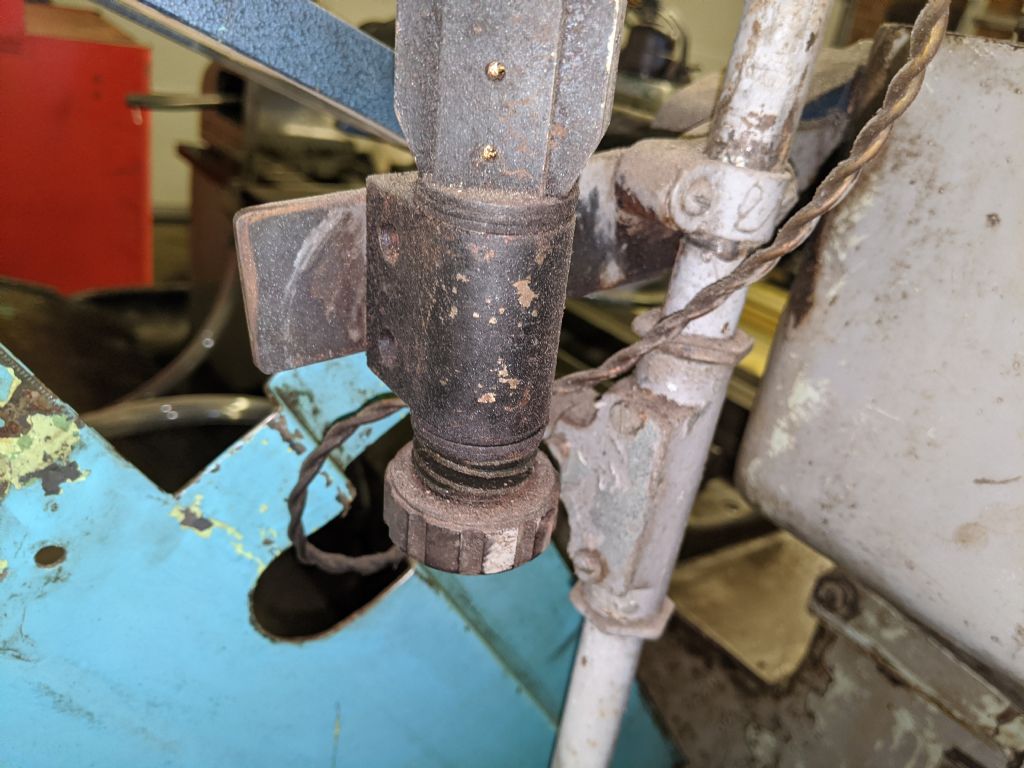

Then I removed the nut that was on the threading indicator mount bit, and I put on the Knurled thingy. Looks and works much better

Then I moved onto trying to swap over the balls. The new ball came off without any struggle, but the old one put up a bit of a fight

Then just onto cleaning

I went to look at the end and try to thread the bolt back into the new one. Looks like there isn't a thread, I'll have to consult the later manuals to see how it should be held in place on the new ones. I think I will probably drill and tap the hole that is there. Possibly m12 if there is enough wall thickness(looks like there should be)

Then I realised that I haven't seen the apron carriage wheels button spacer that goes in the middle. I had it earlier but it's gone walkabout and I cannot find it for the life of me. That's one way to ruin what would have been a perfect night! The search shall continue tomorrow.

I probably won't clean these parts too excessively. I don't see the point polishing them like Herman has(even though his look amazing) Definitely rust-free, but I don't need to be able to see myself, at risk of cracking the parts then!

After all, A LITTLE BIT OF RUST IS NOTHING TO WORRY ABOUT!

Phil Whitley.