Just back from a nice trip to Scarborough to meet John/Ted and Brian, and to have a look through the tools available.

It was like Christmas, but much much better! Tools I hadn't even thought of, and tools that the previous owner had made himself, like centre drills on their own taper so you don't have to fiddle around with chucks. Simple idea, but will save time.

Ted and Brian were both very friendly and we chatted a while. I've come away with quite a few goodies. A few things that I was looking out for anyway, so well worth the trip. Popped in to see a friend in Pickering on the way back too.

Brian gave me a tour of his workshop and it was fantastic. He has a nice smart and brown lathe and plenty of stories to go with it. He also showed me what he's been making over the past couple decades. Incredible stuff. I haven't particularly looked into the model engineering side of having a lathe yet, but now I may be interested. Brian was even kind enough to supply me with various bits of steel and aluminium for me to play with.

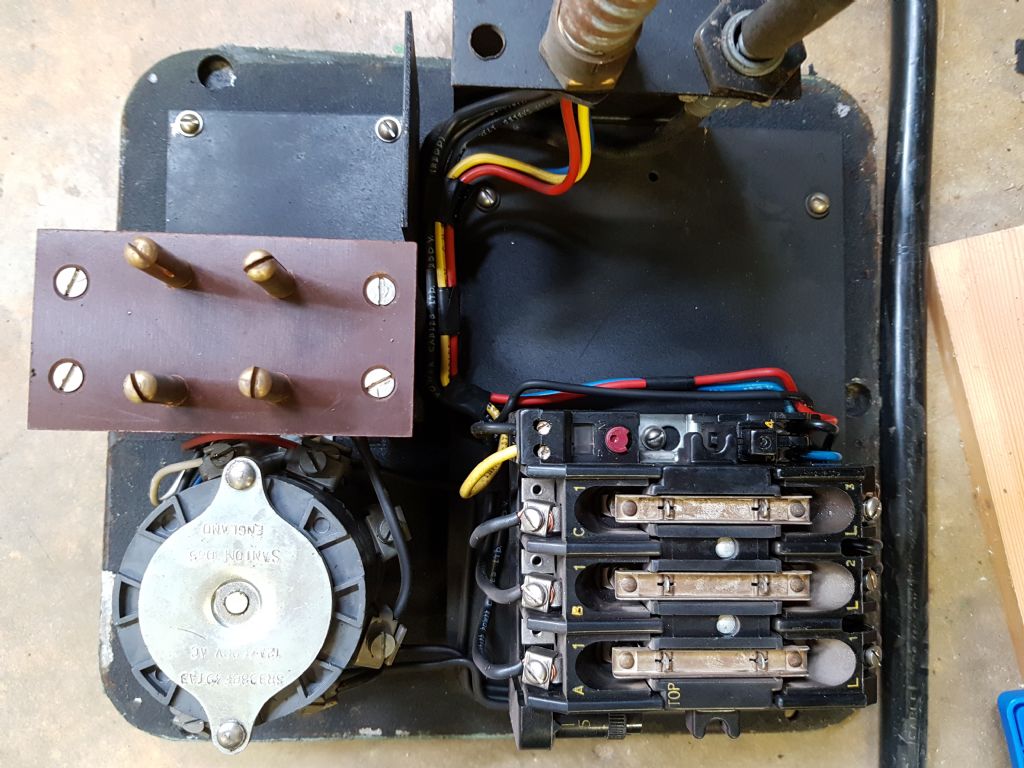

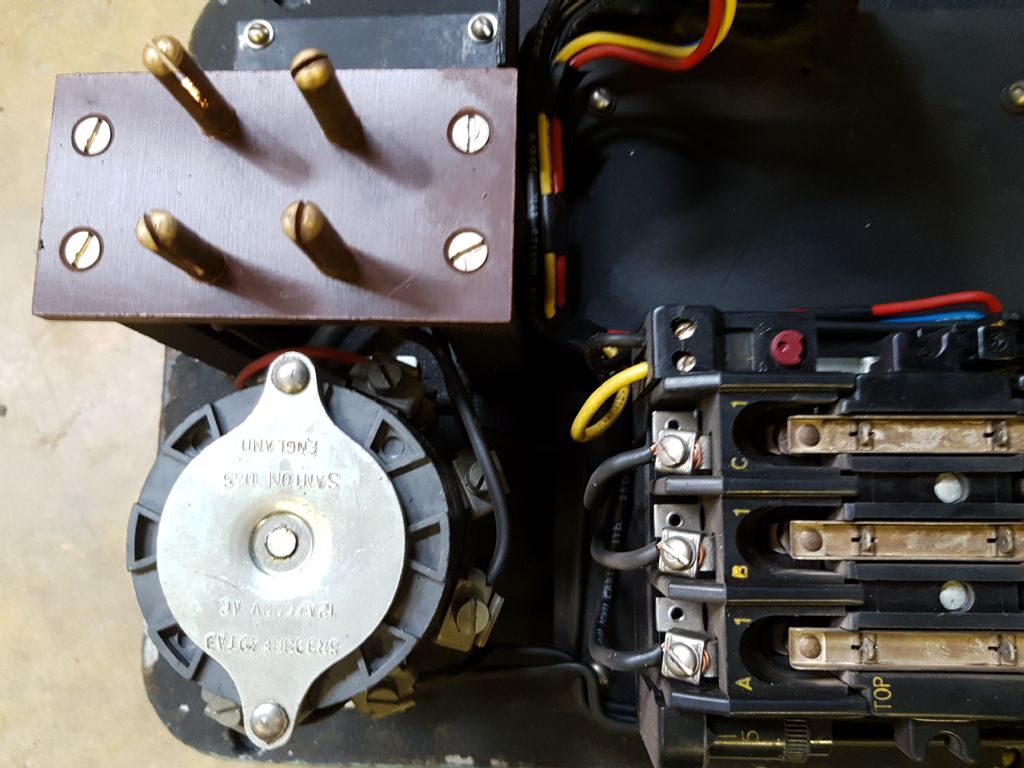

Back home now and tools all laid out, some fantastic bits of kit

So, a few questions from all these tools.

The micrometers have one pin that's round. What are these used for? They looked too good for me to pass up. Are they for wall thickness measuring or something?

The mag chuck doesn't work properly, are they tricky to fix or would it be a waste of my time?

Does anyone know if there are any companies that make cards similar to that starret tap/drill chart but in a full-blown poster form?

That's all for now. A bit off-topic so I apologize. Hijacking my own thread more than Herman at this point!

Meanwhile, I have a lot of tidying and moving around to do in the garage. New homes for tools are required…

Phil Whitley.