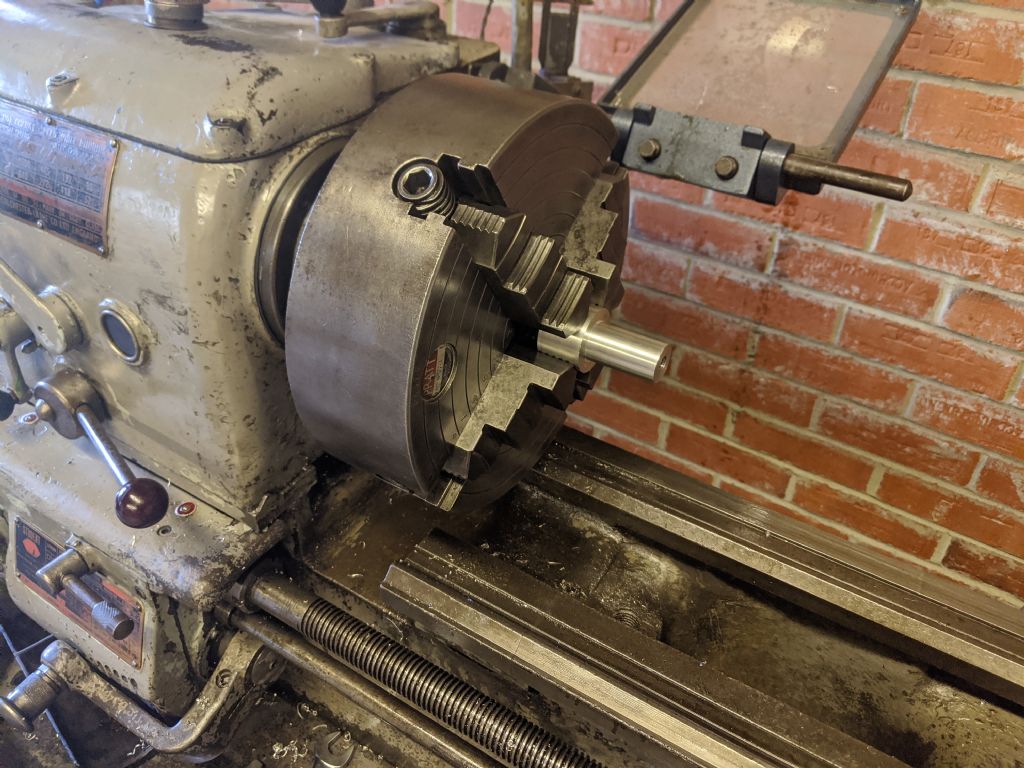

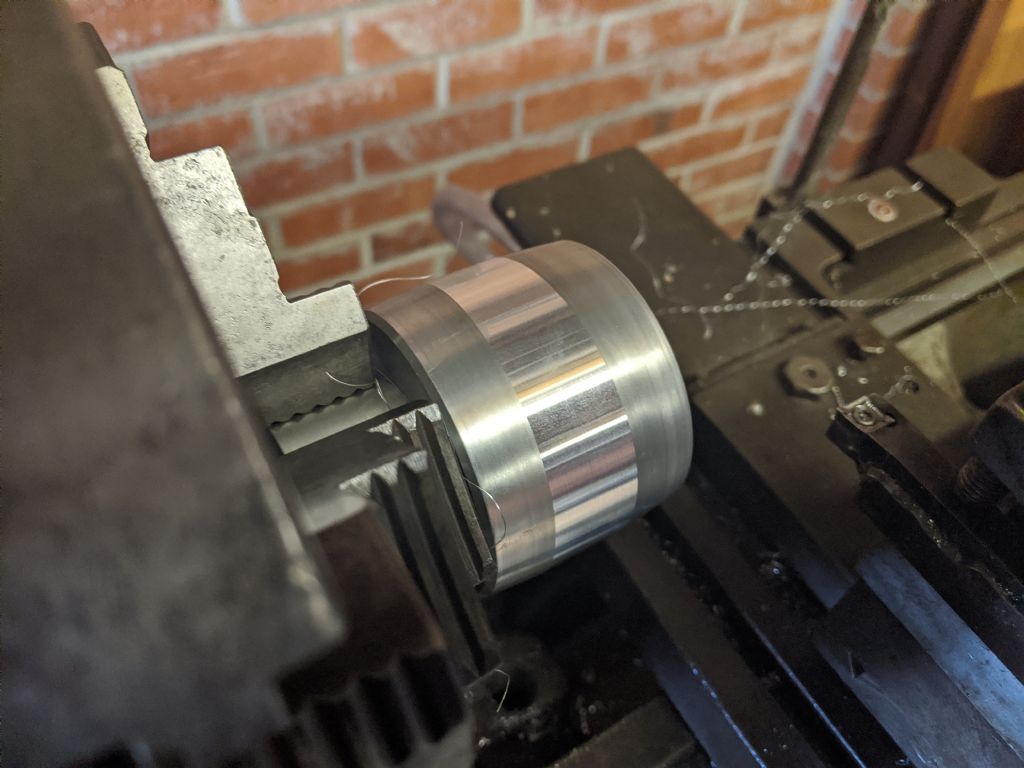

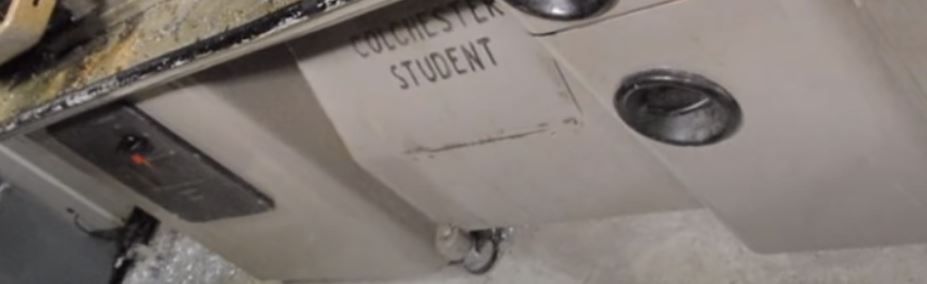

Colchester Student Mk1 Won’t Start

Colchester Student Mk1 Won’t Start

- This topic has 796 replies, 39 voices, and was last updated 5 June 2021 at 16:31 by

Phil Whitley.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Model Engineer Magazine Collection

- Mill drill power feed

- rotational motion into linear motion – force calculation?

- Odd Strain Gauge for Concrete?

- My week this week! My workshop videos

- Superheaters

- Bandsaw alignment

- Odd RAF Specialist Tool?

- Which Carbide Lathe Tools?

- Just How Many File Types Do We Need?