Hi,

I don't have a Bantam but a Harrsion the operation of all geared head lathes is bascally the same.

Lets see if we can break this down into chunks

1. The "apron lever " usually called the third rod switch only lets you run in forward ?

2. The high/low switch now controls spindle direction. ?

3. The leadscrew lever does nothing ?

Issues 1 & 2 are electrical and are related.

Now onto issue 3.

I think 1 & 2 stem from the fact that the lathe was originally 3 phase and has been converted (arguably not that well) to single phase. Reversing 3 phase motors is easy and required less switching than single phase ones.

When you switch your high / low switch does the third rod switch then allow you to run in the opposite direction ?

If so apart from the slightly unconventional set-up you can achieve both direction or rotation.

Originall your lathe had a two speed 3 phase motor – the high & low switch controlled which of the motor speeds was being used. This is was made redundant when they fitted the single speed motor so they used it to change spindle direction.

Your third rod issue can be fixed but it sounds like you don't have much electrical experience and need an electrician – be warned your standard domestic sparky may not be able to help you. You really need someone familliar with motor switching controls, its not difficult but someone doing this all the time will have it sorted out quickly.

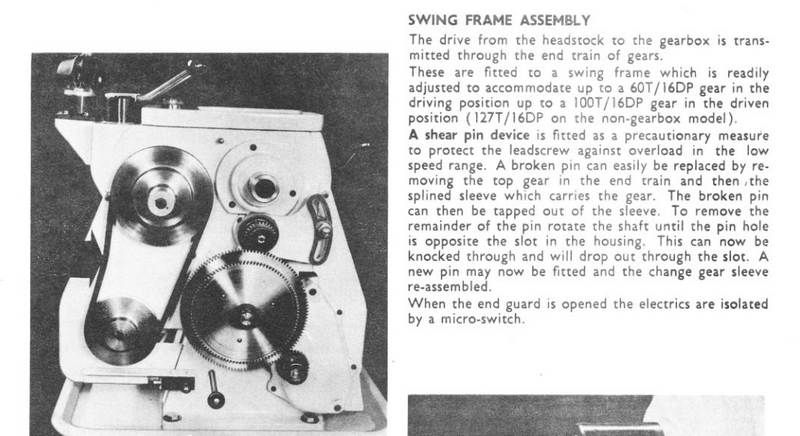

The lathe has two gearboxes – one to control spindle speed the upper one, and anothet – the lower one to control the leadscrew speed and therfore feeds for surfacing and screw cutting. As you are getting nothing it sounds like there is no input power to the lower box. If you take the end cover off you will see a gear train and I suspect that the input shaft to the screwcutting box is not connected to the rest.

If you can post some images of your machine that will give everyone a better idea of the model – and take one of the geartrain inside the end cover.

Don't despair nothing sounds too serious to me

Tony

3 is mechanical

Muzzer.