.

Hi John,

This is what I would do.- Others with more knowledge may have a different solution.

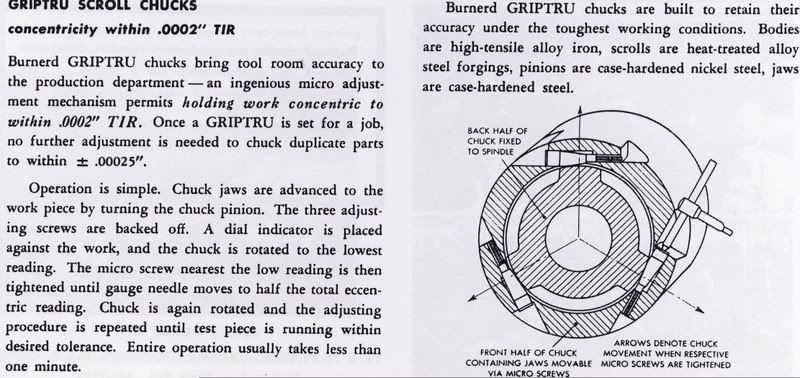

But first let me say that that if you have a Griptru chuck and it's a good one it's a very enviable nice piece of kit.

Get hold of a set of instructions for the chuck and become familiar with how it's adjustment works and how to do so.

Have a good nosey at the jaw faces. (the bits that grip the bar) and check they are even and have not become 'bell mouthed'

Then chuck up some known good round stock. Ground silver steel is good for this, but if you have none order a short length and use what you have for now. This will get you into the 'ball park' and make you familiar with the process for when the ground stuff arrives. I would order a short piece say 12 – 16mm dia.

If possible concoct an adapter so that you can put your dial indicator into the tool post at centre height. That will give a good solid ref point. Take readings from as close to the chuck as you can.

Then apply what you have learned from reading the instructions regarding adjustment.

EDIT :- Also make sure the ALL mounting faces are totally clean. This includes perhaps even removing the chuck from it's adjustable backing plate to confirm this.

Nick

Edited By Nick_G on 02/02/2016 11:03:45

Nick_G.