Chain Hoist Tripod in MEW 264

Chain Hoist Tripod in MEW 264

Home › Forums › Workshop Tools and Tooling › Chain Hoist Tripod in MEW 264

- This topic has 54 replies, 18 voices, and was last updated 11 August 2018 at 21:44 by

Meunier.

-

AuthorPosts

-

5 August 2018 at 06:14 #365628

Ian Austin

Participant@ianaustinI have just had a closer read of an article appearing in Model Engineer's Workshop 264 (February 2018) by Stan Nesbitt on construction of a chain hoist tripod. The design has many advantages I think, in its use of readily available and low-cost parts, its portability and its simplicity. I like it, and intend to make one.

The only thing is, it is a lifting device — and yet no load rating was declared for the tripod itself (though the load limit of the recommended retail chain hoist block is noted). I am surprised that details on its fabrication were published without that information – surely standards apply to lifting devices in the UK as they do in this part of the world, and publication would seem to be an implied endorsement of the tripod's fitness for purpose. No mention either of limits to usage on slopes or such like. Is MEW not a little circumspect when it comes to liability? Or do you not have a thriving industry of personal injury lawyers like over here (Australia), ready to make the most of anyone connected to a mishap?

Well, anyway, MEW's refreshing boldness aside, could anyone venture a load rating on the tripod as shown in the article?

And secondly, the photos show use in soft ground where the legs presumably dig in to prevent splaying. What would be the situation if used on hard smooth ground such as concrete? Are we sure that under maximum load (whatever that might be), there is no tendency for the feet to slide out and splay? I guess not, but I'm no expert.

5 August 2018 at 06:14 #19025Ian Austin

Participant@ianaustin5 August 2018 at 07:39 #365636 David George 1Participant@davidgeorge1

David George 1Participant@davidgeorge1I have used a similar piece of equipment over the entrances to pot holes for lifting rocks and equipment The feet were linked with a chain to prevent splaying and they were adjustable in length to get the hang for the hoist in the correct place and the feet were swivels to suit the terrain with a link welded on to take the chain. It was made from scaffold poles and we used a rope pulley or chain hoist rated at 500kg.

David

5 August 2018 at 07:49 #365637 JasonBModerator@jasonbPosted by David George 1 on 05/08/2018 07:39:04:

JasonBModerator@jasonbPosted by David George 1 on 05/08/2018 07:39:04:I have used a similar piece of equipment over the entrances to pot holes for lifting rocks and equipment ……………..

David

You must have some dad roads in your neck of the woods

I seem to remember a thread about the article at the time of publication but can't easily find it at the moment

Edited By JasonB on 05/08/2018 07:52:24

5 August 2018 at 08:29 #365640Ian Austin

Participant@ianaustinPosted by David George 1 on 05/08/2018 07:39:04:The feet were linked with a chain to prevent splaying and they were adjustable in length to get the hang for the hoist in the correct place and the feet were swivels to suit the terrain with a link welded on to take the chain. It was made from scaffold poles and we used a rope pulley or chain hoist rated at 500kg.

Two interesting points there about your roads tripod — the safety chain, and that it was made from scaffold poles (as is the MEW design) with a block rated to 500kg. Which raises the question whether the MEW design ought really be rated at 500kg rather than being assumed to carry 1000kg.

I also searched for any earlier thread on this tripod design before posting but didn't find one either.

5 August 2018 at 08:44 #365642 Nicholas FarrParticipant@nicholasfarr14254

Nicholas FarrParticipant@nicholasfarr14254Hi Ian, as far as I'm aware, their is no legislation for any lifting equipment made for ones own personal use. If anyone borrows such equipment, that may be a different question. As George says, chains can be used on the lower parts of the tubes to stop splaying out and would certainly be a good addition. However, to make something for lifting that has the potential to sink into soft ground is a bad idea and would not pass any safety tests for a work environment. Personally I have reservations about the "Adapter Plate" where the tubes are relying just on the welds, these tubes in my opinion, should have gussets added, which would prevent any tendency of the plate itself from bending at the welded area. The gussets could be as simple as three flat bars the depth of the tubes, each bar then welded between two of the tubes and along the edge of the adapter plate. I would also obtain a commercially made lifting eye bolt, and shackle if need be, rather than using a U bolt or a bent up bar.

Lifting accidents in industry have been numerus in days gone by, due to poor design and/or faulty equipment and legislation is very strict about testing and maintenance of such equipment here in the UK.

Regards Nick.

Edited By Nicholas Farr on 05/08/2018 08:46:00

5 August 2018 at 08:50 #365644Hopper

Participant@hopperProbably all a bit hypothetical as the whole thing depends on the quality of the home-done welding on the top bracket. As with all home workshop projects, the final onus is on the maker to ensure his own safety. But I'm sure MTM Media has liability insurance so Neil won't have to sell off his collection of Super Adepts if someone sues them after dropping their Rolls-Royce Merlin engine on their foot.

5 August 2018 at 09:27 #365649Ian Austin

Participant@ianaustinPosted by Nicholas Farr on 05/08/2018 08:44:30:Personally I have reservations about the "Adapter Plate" where the tubes are relying just on the welds, these tubes in my opinion, should have gussets added, which would prevent any tendency of the plate itself from bending at the welded area. The gussets could be as simple as three flat bars the depth of the tubes, each bar then welded between two of the tubes and along the edge of the adapter plate. I would also obtain a commercially made lifting eye bolt, and shackle if need be, rather than using a U bolt or a bent up bar.

You've expressed something that was in the back of my mind about the 'adapter plate' — that the weld-ons didn't look the full business, especially the hook-eye in the centre which would be under considerable tension and high dynamic loads if anything was swinging or especially if the load suddenly slipped. Yes, a commercial solution there, although I'm still trying to visualise exactly what, would be better than the weedy U-bolt weld-on. And good point about gussets on the pole sockets, just right.

The quality of the welds is beyond MEW's control, but given the history of industrial accidents with lifting equipment, hence the web of design standards, workplace legislation and case law around them, the design ought to have been given a stated rating as part and parcel of publication — it's the act of publication that raises the level of due diligence. Other than the lawyer's picnic if the design/author/publisher can be upheld as a contributor to injury, its all about safety first.

5 August 2018 at 10:13 #365656Clive Foster

Participant@clivefoster55965Bit of a tizwaz in a teacup here.

Up to a short ton or so lifting structures tend to fall into the "if its stiff enough its strong enough" category. So long as it doesn't wobble about all over the place and looks about right on a "monkey see, monkey do" basis relative to normal practice such things are almost certain to be safe in occasional by a reasonably intelligent person. Outside of grossly incompetent construction of course its actually quite difficult for anyone with a reasonable degree of mechanical nous to come up with something that is terminally inadequate. Iffy maybe but terminally bad no.

Generally the most likely issue is using too weak a bit of string or bad knots. (Like far too many folk I can't do a lorry drivers hitch for love nor money despite being shown a dozen or more times and have to concentrate to avoid producing a granny knot!). Bloke who helped me shift my lathes and mill, all pushing ton and a half frightened me silly but nothing actually broke.

It may be instructive to look closely at what actually carries the load on commercial systems. Usually a quite small pin. Also instructive to look at how things are attached. The common Penny Hydraulics et al swing lifts look satisfactorily hefty as do the truck bed cranes so common in America. But closer inspection into how they are actually mounted reveals simple angle reinforcement of plain sheet metal at best. Apparent heftiness is mostly for show. Bending may be quite safe but it looks well iffy. The popular folding engine hoists are similar in that all the load goes through a couple of 3/8" or 1/2" Ø pins.

Or look at the simple sheet metal brackets beloved of builders to hang joists and cross beams on walls. Eeek! OK building joints are always weak. Far as I can see most house and similar size buildings stay up because everything is leaning against everything else and nothing wants to be first mover.

Regulations are set to cover edge cases, abuse, uncaring folk in a hurry and negligent slave driver type employers. At the lower end covering the safety factor takes more effort than the load.

Go past a ton and its time to get serious tho'.

Clive.

Edited By Clive Foster on 05/08/2018 10:13:53

5 August 2018 at 10:38 #365658 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattAs it has been drawn to my attention that the design could be improved, I am happy to publish a follow up to the article that emphasises the safety of the tripod is determined by the quality of the welding and materials used and that a few steps might help make it more robust. One addition suggest is nuts for the u- bolt as well as weld. Not everyone has the author's welding skills.

In actually got a good letter from a reader with advice on improvements, but for some reason it didn't get published. I will make sure it appears.

My correspondent helpfully signposts the HSE website regarding the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER). Although these don't apply to home situations, they have useful advice (as does most of the HSE website).

If we published a 'rating' for the tripod, then that would be stating it was fit for a certain purpose. As we have no control over the quality ot reader's work, that would be irresponsible. Also, if we published a rating, who would certify it? The only way would be to get the design signed off by a professional engineer, which is unlikely to be cost effective.

Every article we publish involves potentially hazardous actions. We have to rely on our readers to assess the hazards, take action to limit the risks (such as using guards on machines, working within their capabilities and testing any devices before use etc.)

We do draw attention to any special hazards, such as the need to be competent to work one electrics, for example. I'm adding lifting gear to the categories for which we need to advise special care is taken.

Neil

5 August 2018 at 10:49 #365662richardandtracy

Participant@richardandtracyI made an A frame support frame from pallet timber about 10 years back. The main timbers were 3×3 and 4×2 info. Stressed it after building and ended up with a conservative 1.5 tonne breaking load, so rated it at .25 tonne with a reserve of 6. Home stuff can be very over designed. Left it outside over winter and wouldn't trust it after that – so it became firewood.

On the 'Backyardmetslcasting.com' site Lionel shows a lifting frame picking a motorcycle off his Ute. That one is strong enough, but not safe due to the risk of offset loads and swinging. Needs a couple of braces otherwise the welds could fail due to lack of triangulation. It's from simple scaffold pole.

Regards

Richard

5 August 2018 at 11:00 #365665 Mike PooleParticipant@mikepoole82104

Mike PooleParticipant@mikepoole82104I think proof testing lifting gear to well over its safe working load is how insurance checks are done. I would suggest doing a proof check at perhaps double your normal lifting requirement and then rate it accordingly. Any signs of distress during the proof test may show the weak spots in the design. I think the object of the test is to pass with no signs of permanent distortion or breakage. Simple to use crack testing sprays are availableto check things are not failing after a period of use. I would use a person who can weld properly to fabricate lifting gear as it is difficult to say a weld is ok just by looking although some welds are definitely not ok just by looking.

Mike

Edited By Mike Poole on 05/08/2018 11:07:03

5 August 2018 at 11:24 #365670Ian Austin

Participant@ianaustinNeil, yes you have a difficult path to negotiate there, because of the home welding wildcard — I recall when I welded some brackets for a friend, I hadn't hard-tightened the big slider knob for the current, and the buzzing had slowly pulled the knob in, reducing the current. The welds still looked ok, but once I’d done, I realised you could just snap them apart. And then there’s the issue of welding galvanised pipe/plate – if you don’t know to grind off the zinc plating, the weld just peels off later on. And yet, here’s a design for a hoist frame that might have a tonne swinging off it. So yes, lots of factors.

And yet, if you don’t recommend an upper load limit for the design, you’ve got the possibility that someone not tuned in to what they are doing might try to lift something that perhaps this design, even if well-made, really can’t support. At the moment nobody knows what that limit is – it’s just a guess. I would probably say 500kg (if made well, and allowing a safety factor because of dynamic loading) but someone else might say she’ll be right for 1500kg. As it stands, who knows?

A load rating has to be stated, even if you have to pay £300 or whatever for an engineer to sign off on a design (not a product). That’s the burden of publishing. And that engineer would be specifying that the welds, the steel, the dimensions, the hooks, the chain, and so on are all to relevant British Standards. And add to that, that the operator is aware of proper operation. If the specification is done, and the warning is there that that is the deal, then the culpability is probably lowered right down. At the moment, by holding onto the idea that it’s better to stay stumm on these aspects, even though you've now published a design, over here in Australia you’d be a walking lawyer’s target. The way case law has progressed on liability over the last few years, it’s just scary.

If you look at the Australian Model Engineering mag, or the Australian diy websites, everyone is very careful about what they say publicly around anything that should be certified – electricals, boilers etc. Model boilers all have to be built to standards, tested and certified. Electricals hard wired to the supply, or even not, always have some version of a statement to used a qualified electrician. Yes, it might be arse covering but who wants to be a sacrificial bunny? I don’t know about the UK.

Of course, the other way to go on publishing on things like a hoist is not to offer a specific design for fabrication and use, but to simply discuss what’s on the market, especially here in this case, of the ‘scaffold pole’ type (the type in the article) apparently which is also a type sold commercially, mentioned by David George above in connection with roadwork. If some fellow then says in his workshop ‘I could make that’, goes ahead and injures himself or someone else as a result, that’s on him.

All that said, I’m personally happy that the design is there – as a start to my own ideas – but see how already we’re talking about how it’s not a great published design and needs improvement.

5 August 2018 at 11:28 #365672 Martin ConnellyParticipant@martinconnelly55370

Martin ConnellyParticipant@martinconnelly55370If this tripod was being designed and manufactured for sale then calculations of compressive, tensile and shear forces would be carried out and retained by the company doing the work. Scaffold pole is basically 1.1/2" sch40 mild steel pipe that has been galvanised. Since the slenderness ratio is quite large Euler's formula would be used to calculate maximum possible loading and this would be reduced by some suitable factor for a working load limit (WLL ). Similar calculations apply to all other parts in the design. Finally after manufacture a load test would be carried out and the item marked with a serial number and have a certificate issued. In industry the item would be given an initial inspection to check it was supplied undamaged, correctly marked, correctly certified and suitable for its intended use. Once in use it would be expected to be given a pre-use visual check, a post use visual check and storage in a way that will keep it safe. It will also have an annual thorough check by a competent examiner who is preferably independent from the company using the equipment. None of this is expected for private individuals but if you are suggesting your design for other people's use then failure to supply the calculations and intended setup and use could land you in court if something goes wrong.

It is also important to understand the difference between working load limit (WLL ) and safe working load (SWL ). For example a sling may be supplied with a WLL of 1000kg but the SWL is dependent upon the lift configuration and may be well below 1000kg.

The rules have evolved over years due to the history of death and injury caused by poor lifting equipment and inappropriate or poorly configured lifts. It still occurs where people claim it was ok because we have always done it like this and this is the first time we have had an accident. Investigations show that usually it was an unsafe lift and luck has played a big part in the lack of accidents.

Martin C

5 August 2018 at 12:04 #365676Ian Austin

Participant@ianaustinSome nice comments there — Martin C has nailed the engineering far, far better then me.

I guess the legal defence is that MEW never specifically endorsed the design for replication — so it would be up to any injured party (if that were to occur) to argue that by the design's publication the plaintiff took it as an endorsement the design was suitable as a diy project to be replicated (contextualised in a diy magazine after all, full of designs there to be replicated). After all, the article never warned that that was not the case. There was no safety warning, guidelines, discussion of dangers or advice not to try this at home. I'd bet on the injured party winning, but who knows.

One good thing is that the design knocks down to scaffold poles and a strange triangular plate thingy — rather than being a permanently assembled unit, so it isn't something that would be sold on masquerading as an approved lifting device (intentionally or not) in, for example, an estate sale after the maker's death.

5 August 2018 at 12:28 #365677 JasonBModerator@jasonbPosted by Ian Austin on 05/08/2018 11:24:26:

JasonBModerator@jasonbPosted by Ian Austin on 05/08/2018 11:24:26:Of course, the other way to go on publishing on things like a hoist is not to offer a specific design for fabrication and use, but to simply discuss what’s on the market, especially here in this case, of the ‘scaffold pole’ type (the type in the article) apparently which is also a type sold commercially, mentioned by David George above in connection with roadwork. If some fellow then says in his workshop ‘I could make that’, goes ahead and injures himself or someone else as a result, that’s on him.

Just to avoid confusing I believe David was talking about pot holes as in pot holing not pot holes in the road. Though the 3 leg design can often be seen above a man hole in the road to hoist both people and equipment.

5 August 2018 at 12:34 #365679Farmboy

Participant@farmboyPhew!

After reading a couple of recent threads here I'm surprised anybody bothers to submit articles for publication. They certainly need to be thick skinned.

I haven't seen the offending article in this case, but most of the time the writer is showing us something he made, and how he went about it. Nobody is obliged to replicate it, and if they do they'll most likely modify things to suit their purpose or available materials.

I'm just grateful that people are prepared to share their experiences, either in the magazines or on forums like this.

Mike.

5 August 2018 at 12:44 #365682SillyOldDuffer

Moderator@sillyolddufferFor what is's worth, Stan uses 3 Kwikstage standards for his tripod. In normal use, they would be vertical, and an accurate calculation would have to take that into account. However, depending on height and configuration when used as scaffolding, Kwikstage rate the standards at either 18kN or 25kN. (Likely this allows a safety factor of 6.)

Say the standards are only good for 10kN angled over in Stan's tripod (an under-estimate for sure). They would take a combined load of 30kN safely, which is about 3 tons, well above the 1000kg limit of the chain-hoist. Looks good to me.

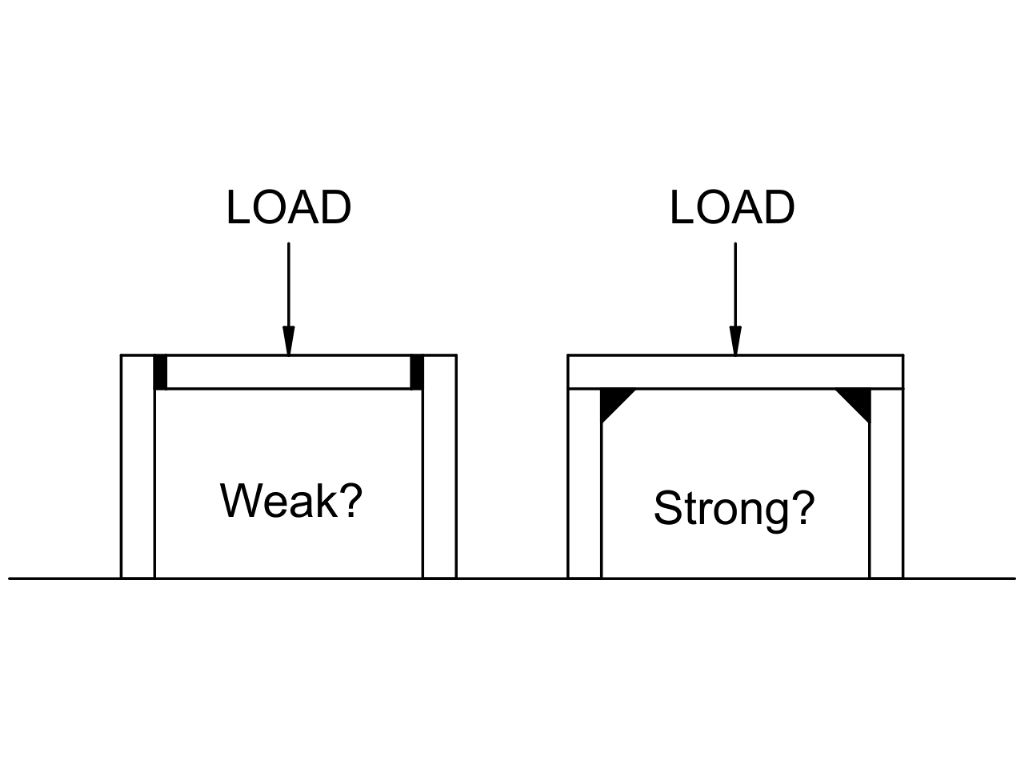

I've no experience of welding, but would the adapter plate be stronger if the triangle rested on top of the tubes, rather than being welded to their sides? If the plate were welded in position resting on top, the welds wouldn't have to take the full load as they do at the moment.

Dave

5 August 2018 at 12:50 #365683Hopper

Participant@hopperIn theory, the weld should be as strong as the parent metal. In practice in the home workshop, your second example looks like a good idea. It's the way I would do it, being familiar with my own welding skills!

5 August 2018 at 12:53 #365684 David George 1Participant@davidgeorge1

David George 1Participant@davidgeorge1Talking about potholes. when I started I just used what every one else use which was a spit rock anchor which was 10mm diameter and 30 mm long with an 8mm taped hole in the end. you drilled a hole to suit the anchor placed the anchor in the hole and set it by driving a tapered wedge down the centre. you then used an 8mm bolt and plate to connect your ropes to the drop from these could be hundreds of feet but you had a backup and used two to be sure. As the thread wore with continually screwing in muddy screws sometimes they striped and a couple of near misses happened. We had a thought and with cooperation with British Mountaineering Council came up with the new idea of resin fixed anchors where a preformed anchor was set into a deeper hole permanently so don't do as you always have look at the equipment for safely lifting as your life may rely on it.

David

5 August 2018 at 13:37 #365689Ian Austin

Participant@ianaustinThanks Dave, that's the kind of rough estimate I was looking for to see if this design would suit loads to my probable limit of about 500kg, and it would seem that it would do, other factors being acceptable.

The ideas for reconfiguring the plate are welcome. Not being a professional welder I can't assume that my welds are good enough to guarantee safety in all circumstances, so looking for redundancies or natural advantages as in your diagram B, rather than skimpy theoretical minimalism relying on weld strength alone as in A, is a better option for me.

As to personal injury liability, it's definitely moved on from the old days of common sense. It used to be your own fault if you were a dimwit. Now we all have to keep in mind "what if a dimwit got hold of this", regardless of what common sense we might expect people to have. Hence the need for disclaimers and safety statements inserted by editors. But once the disclaimers, warnings and proper use statements are all dutifully done (as in any modern tool operation manual), there's no need to back away from what we like to do.

5 August 2018 at 14:04 #365695Samsaranda

Participant@samsarandaThe subject of lifting heavy equipment with home constructed solutions seems to have raised much communication about the fear of litigation if anything goes wrong. In the case of the article mentioned the author has illustrated how he tackled the problem of lifting using his acquired knowledge to fabricate a solution. If a reader were to use his article as a pattern for solving a similar problem then any responsibility would rest with the reader as the original article is only a suggestion of the way forward and doesn’t give any load or stress calculations for the equipment so subsequent use for any purpose would be a unique use by the reader. If there was an accident and any subsequent injuries then responsibility would clearly rest with the person responsible for constructing the equipment. In the mid 60’s I was working on a Salvage and Transportation Unit in the Air Force and we had to construct our own lifting equipment when in the field, recovering aircraft wreckage or moving abnormal loads for which there was no specific lifting equipment, this could be using homemade slings constructed from steel cables or using combinations of hydraulic jacks and the ubiquitous railway sleepers. We managed because you very quickly acquire that sixth sense as to whether your judgement is sound or not, we never had any serious mishaps, but one overriding rule recognised by all concerned was Never put yourself under a suspended load, I wish that this was universal I frequently see operatives wandering under suspended loads and my blood runs cold with thought of the possibilities that could occur. Neil I think some readers have been worrying unnecessarily about possible legal consequences of articles published in the magazine, I think that it would be a sad day if we were to lose the diversity and interest that comes with the variety of content in the magazine, keep it going just as it is.

Dave W

5 August 2018 at 14:07 #365697 Neil WyattModerator@neilwyattPosted by Ian Austin on 05/08/2018 11:24:26:

Neil WyattModerator@neilwyattPosted by Ian Austin on 05/08/2018 11:24:26:A load rating has to be stated, even if you have to pay £300 or whatever for an engineer to sign off on a design (not a product). That’s the burden of publishing.

I'm sorry Ian, that's simply not the case.

If it was, we would basically have to stop publishing the magazine and half the people who have posted on this site would be exposing themselves to vicarious liability for offering advice.

Neil

Edited By Neil Wyatt on 05/08/2018 14:08:14

5 August 2018 at 14:10 #365699 Neil WyattModerator@neilwyattPosted by Samsaranda on 05/08/2018 14:04:27:

Neil WyattModerator@neilwyattPosted by Samsaranda on 05/08/2018 14:04:27:The subject of lifting heavy equipment with home constructed solutions seems to have raised much communication about the fear of litigation if anything goes wrong. In the case of the article mentioned the author has illustrated how he tackled the problem of lifting using his acquired knowledge to fabricate a solution. If a reader were to use his article as a pattern for solving a similar problem then any responsibility would rest with the reader as the original article is only a suggestion of the way forward and doesn’t give any load or stress calculations for the equipment so subsequent use for any purpose would be a unique use by the reader. If there was an accident and any subsequent injuries then responsibility would clearly rest with the person responsible for constructing the equipment. In the mid 60’s I was working on a Salvage and Transportation Unit in the Air Force and we had to construct our own lifting equipment when in the field, recovering aircraft wreckage or moving abnormal loads for which there was no specific lifting equipment, this could be using homemade slings constructed from steel cables or using combinations of hydraulic jacks and the ubiquitous railway sleepers. We managed because you very quickly acquire that sixth sense as to whether your judgement is sound or not, we never had any serious mishaps, but one overriding rule recognised by all concerned was Never put yourself under a suspended load, I wish that this was universal I frequently see operatives wandering under suspended loads and my blood runs cold with thought of the possibilities that could occur. Neil I think some readers have been worrying unnecessarily about possible legal consequences of articles published in the magazine, I think that it would be a sad day if we were to lose the diversity and interest that comes with the variety of content in the magazine, keep it going just as it is.

Dave W

Thank you Dave.

That's my understanding too.

'Rating' a design as Ian says is the thing that woudl actually create a liability as you are then explicitly stating it is suitable for a particular purpose.

Neil

5 August 2018 at 14:18 #365703 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattI should also add that the magazine contains the usual notice in the front and it does specifically state "Reliance placed upon the contents of this magazine is at reader's own risk".

Notwithstanding that I do take care to highlight possible risks, often adding a short comment or making and edit to submitted articles.

In this case, I will be publishing advice on how to make the design stronger (fillets and nuts as well as weld on the U-bolt).

It is clear to readers that this is a hobby magazine and that the articles in it, by and large, are written by hobbyists, not professional engineers, and should be treated as such.

Neil

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Workshop Tools and Tooling › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Bendy Flexible Plywood

Started by:

Henry Buckeldee in: Related Hobbies including Vehicle Restoration

- 3

- 3

-

27 August 2025 at 19:43

Bazyle

Bazyle

-

Weird electric actuator action

Started by:

ell81 in: Beginners questions

- 5

- 5

-

27 August 2025 at 17:42

Robert Atkinson 2

Robert Atkinson 2

-

Damp engine, Name?

Started by:

sivtek1 in: Stationary engines

- 5

- 11

-

27 August 2025 at 17:15

sivtek1

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 35

- 230

-

27 August 2025 at 16:55

Durhambuilder

-

Marcus Oxen … illustrated notebook

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 2

- 2

-

27 August 2025 at 16:45

Harry Wilkes

Harry Wilkes

-

Lathe tool inserts

Started by:

Andy Brocklehurst in: Beginners questions

- 9

- 15

-

27 August 2025 at 14:21

Vic

Vic

-

Museum donation

Started by:

Stephen Wessel 1 in: Introduce Yourself – New members start here!

- 4

- 5

-

27 August 2025 at 13:06

Michael Gilligan

Michael Gilligan

-

Softening epoxy

1

2

Started by:

John Haine in: General Questions

- 21

- 38

-

27 August 2025 at 12:56

Robert Atkinson 2

Robert Atkinson 2

-

Granville lathe leadscrew change wheel

1

2

Started by:

JACK SIDEBOTHAM in: Help and Assistance! (Offered or Wanted)

- 13

- 30

-

27 August 2025 at 12:09

cogdobbler

cogdobbler

-

Hereward

Started by:

Richard Simpson

in: Model Boats

Richard Simpson

in: Model Boats

- 6

- 11

-

27 August 2025 at 11:06

cogdobbler

cogdobbler

-

Imperial Bearing Surprise!

Started by:

Peter_H in: General Questions

- 4

- 4

-

27 August 2025 at 10:06

tonychap

-

QCTP for chester lathe

1

2

Started by:

Chris12 in: Beginners questions

- 12

- 32

-

27 August 2025 at 08:17

Vic

Vic

-

Bending copper tube?

Started by:

Bo’sun in: Workshop Techniques

- 13

- 16

-

27 August 2025 at 02:05

cogdobbler

cogdobbler

-

The skill of the Victorian woodcut engraver

Started by:

vic newey

in: The Tea Room

vic newey

in: The Tea Room

- 5

- 6

-

26 August 2025 at 22:12

SillyOldDuffer

-

Smart & Brown Model L lathe help required

Started by:

AJAX in: Manual machine tools

- 4

- 11

-

26 August 2025 at 21:40

AJAX

-

Myford VMB mill, head lift.

Started by:

lctikka61 in: Manual machine tools

- 3

- 3

-

26 August 2025 at 20:41

Alan Wood 4

-

Raab Style Heibluftmotor

Started by:

JasonB

in: Miscellaneous models

JasonB

in: Miscellaneous models

- 3

- 7

-

26 August 2025 at 18:53

JasonB

JasonB

-

3.5″ Derby 4F – First Loco Build

Started by:

mattleicester

in: Locomotives

mattleicester

in: Locomotives

- 5

- 5

-

26 August 2025 at 17:51

paul rushmer

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 12

- 16

-

26 August 2025 at 15:28

simondavies3

-

3″ Castings – Help/Advice needed

Started by:

Andy Porter 1 in: Traction engines

- 5

- 11

-

26 August 2025 at 12:37

parovoz

-

Valve gear problem

Started by:

John Billard 1 in: Locomotives

- 3

- 3

-

26 August 2025 at 09:08

Charles Lamont

-

Recommendations for book on clock repairs

Started by:

Andy Stopford in: Clocks and Scientific Instruments

- 8

- 10

-

25 August 2025 at 21:15

Andy Stopford

-

Drain Cock search

Started by:

Speedy Builder5 in: Locomotives

- 4

- 8

-

25 August 2025 at 16:48

Diogenes

-

Blackgates 3 Way Toolpost Casting

Started by:

John McCulla in: Materials

- 15

- 25

-

25 August 2025 at 16:06

Nicholas Farr

Nicholas Farr

-

Quartz clock movement

Started by:

duncan webster 1 in: Electronics in the Workshop

- 4

- 6

-

25 August 2025 at 10:24

Michael Gilligan

Michael Gilligan

-

Bendy Flexible Plywood

-