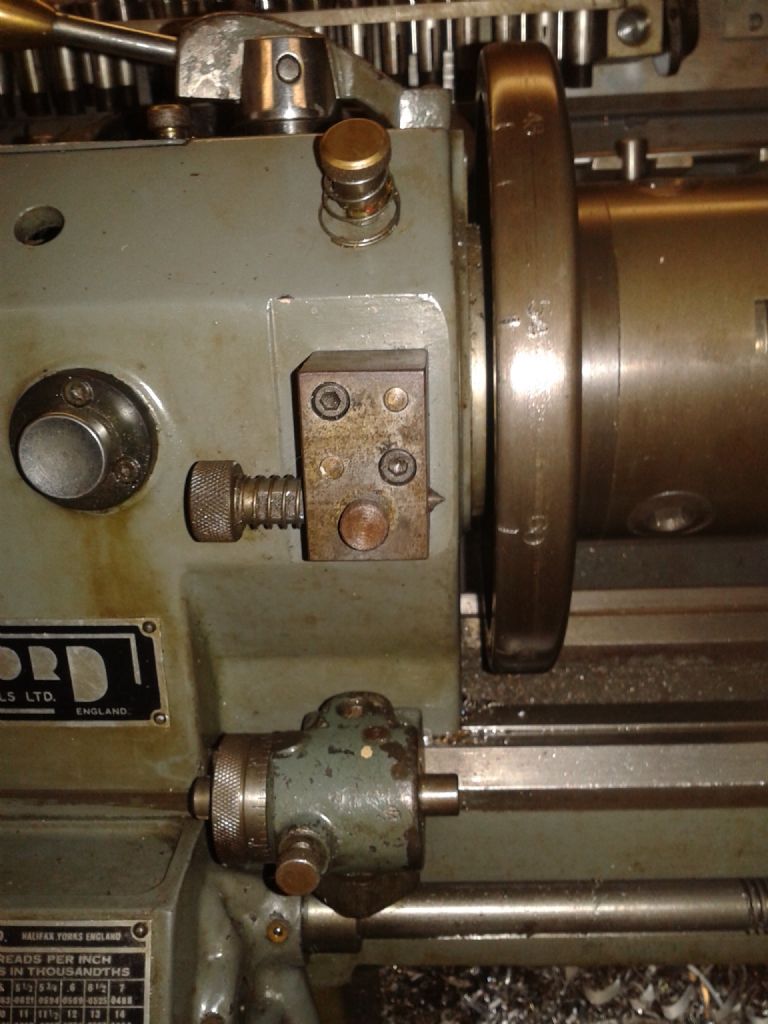

I personally do not think its an ex Boxford factory fit for several reasons:

The dimple locations in place of more positive parallel pin locaters indicate to me it was intended for nothing more than angular marking out. A research establishment would not need to do this on a lathe. They would have much better equipment for this purpose. As others have said there is/are no other signs of provision for additional machining or work holding on the lathe to supplement anything else other than this.

It would more than likely be far more beneficial to somebody who did not have other means to provide indexing, does not have a milling machine and/or just has a good bench or pillar drill.

5 degree increments would be a good single incremental denominator for home workshop engineering, to supplement many subsequent drilling operations.

I do not think Boxford would clamp a locating block on the headstock directly on a painted surface, not good practise for any machine tool maker. I do think that Boxford if they had fitted the block, they would also have painted the block.

When this lathe was produced, good indexing equipent was very expensive and beyond the economical reach of many home engineers, especially in smaller proportions.

As others have mentioned, It was not uncommen for machine tool makers to supply a pot of paint with the lathe so could easily have been done by an owner.

For somebody building up their home workshop portfolio, lots of jobs like skimming the headstock, making the index plate, the location block etc could well have been done at their workplace as "foreigners".

My comments are in no way intended to be derogatory to the owner, in fact quite the contrary as for a Boxford AUD I think its actually right up there amongst the top ones i have ever seen, ( and owned ) especially in their original paint.

Having recently been on an invited factory tour of the Boxford factory I must say there is no resemblance to the historical pictures you see of their once main line production facility that was producing the machines that most people know them for.

I also respect the comments the OP posted about the Colchesters as I also had the round header Master and sorely missed it after I had my last Boxford AUD, such that I moved the Boxford on, in favour of a bigger machine.

Edited By MalcB on 12/02/2017 09:24:35

thaiguzzi.