RPM = cutting speed (metres/min) / circumference (metres)

Aluminium has by far the highest recommended cutting speed of all the common materials in our workshops, at 75 to 105 metres/min for HSS tools and 900 to 2200 metres/min with an uncoated polished insert.

At the lower end, on a 50mm diameter bore, that translates to 500 – 668rpm for HSS and 5732 – 14102rpm for a tipped tool. Two limiting factors have already been mentioned: lathe top speed and chuck rating.

So; run the lathe at top speed, but expect the carriage feed rate to be slow. The tipped tool rpm are well outside the Myford/Boxford/mini-lathe speeds, but that will not prevent the tips working reasonably well. I certainly would not be inclined to attempt this job with HSS tools, but opinions (and results) vary. I machine aluminium frequently on the lathe and the mill and have found the tipped tools or polished carbide cutters ground with cutting angles specifically designed for aluminium to be the answer to the clogging and sticking problem. Flood coolant helps too, of course, if you can stand the mess. WD40 stinks too much for me. Carnauba wax works too, but is too laborious to apply, and too expensive. Neat cutting oil works, as does water-soluble cutting oil. Application by toothbrush is too much effort, on a time-consuming job like this.

Some manual lathes (Hardinge, for example) can run at 5000rpm, and suitably rated chucks are available at a price.

The smaller diameter stages of drilling and initial boring will work best at correspondingly higher rpm.

In the end, we do what we can with what we have, and a 50mm hole is perfectly achievable without too much difficulty (except, as previously noted, for the copious swarf).

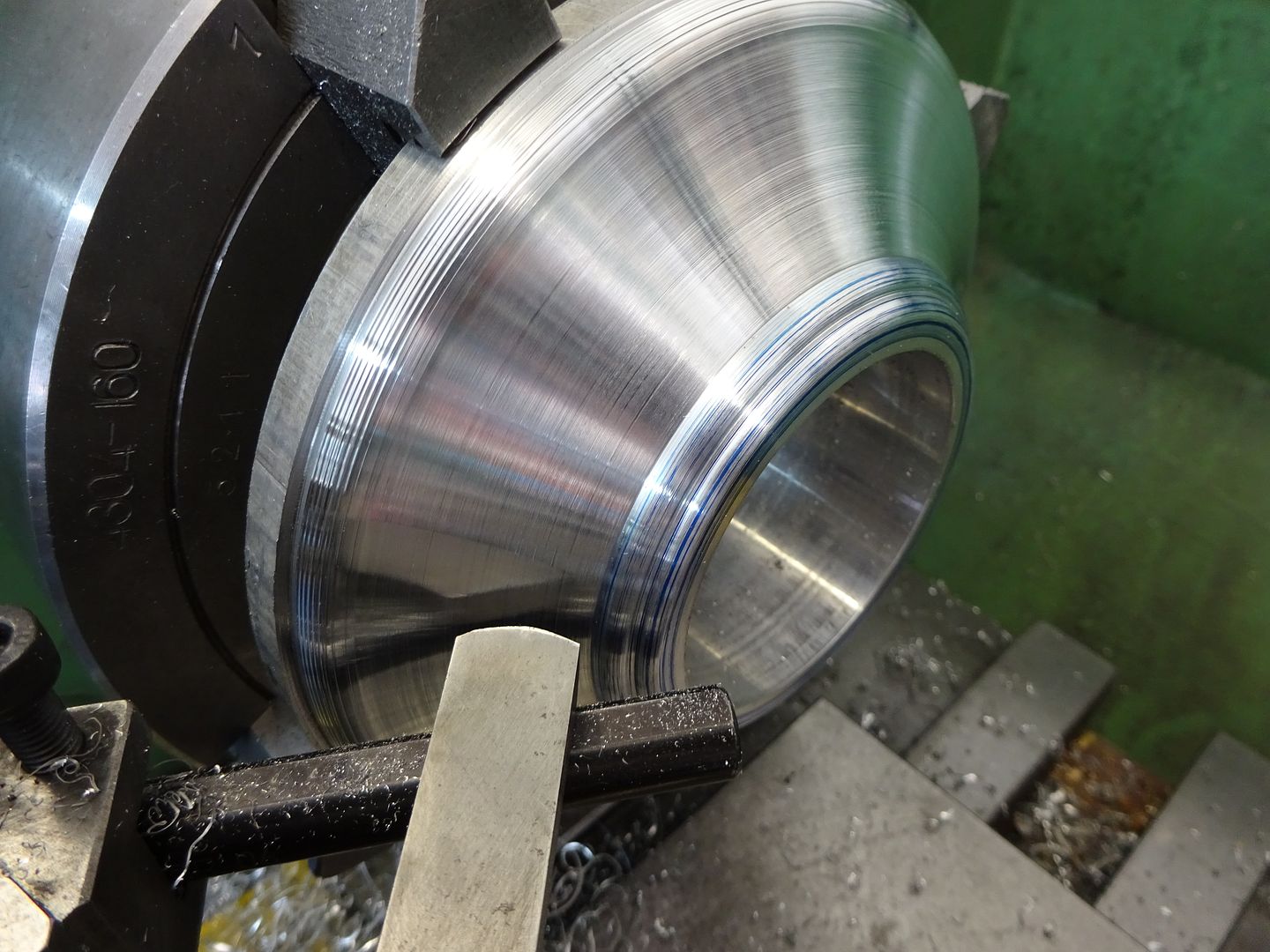

Despite the higher recommended speeds, I would simply use top speed and be content with the chrome-like finish on the final finishing cuts. Wondrous to behold.

Two other points:

The work needs to be gripped in such a way that there is clearance behind the work for the cutter to pass through without hitting chuck or faceplate, at maximum cut diameter.

The boring bar for the final stages needs to be stiff and/or of large diameter, to prevent 'ringing', and to provide sufficient rigidity for the finishing cuts. It depends on the finish you need on the job.

Marcus

Hillclimber.