Welcome, and congratulations on your new acquisition. You are unlikely to regret it, and a whole new world of things that can be done will open up for you!

If the lathe does not have the manual with it, try to find one. It is pretty basic, but one rule to observe always, is never to start or stop the lathe with the speed control set to anything other than ZERO.

Otherwise, you are liable to damage the control board! (Expensive )

The manual will tell you haw to operate the machine, with guidance on depth of cut and, when the need arises, how to set up the change gears.

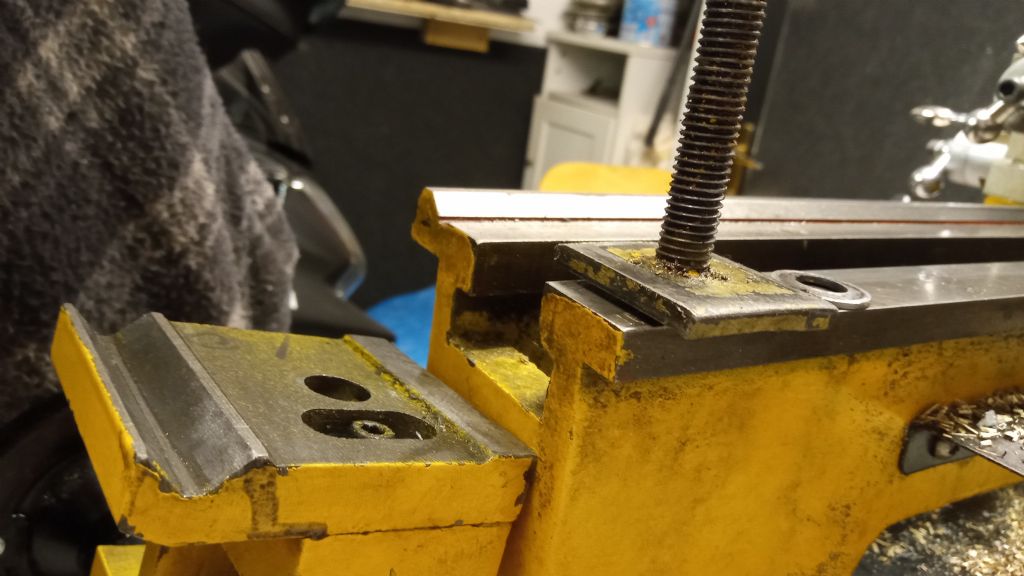

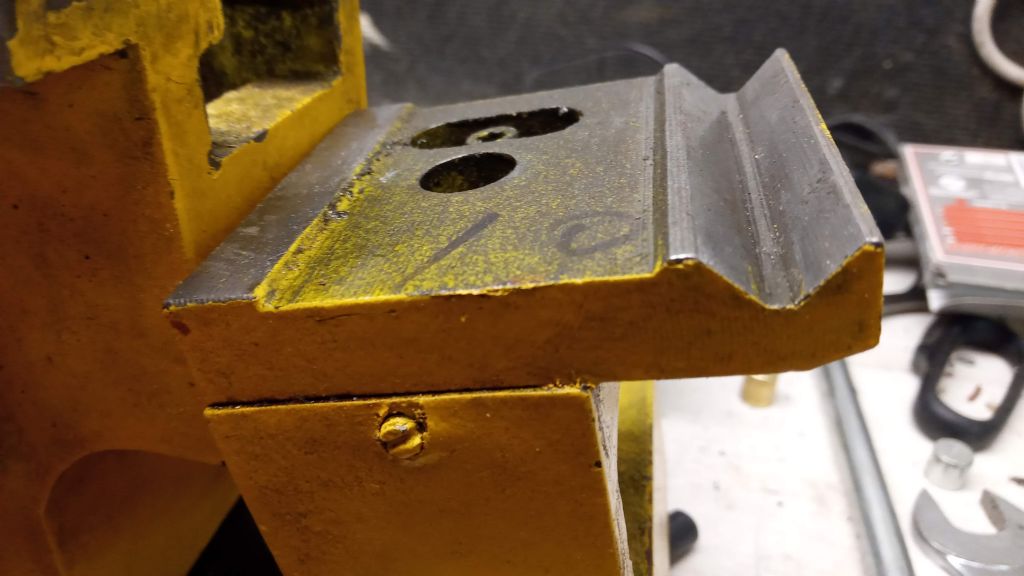

The Tailstock looks to be out of alignment. If you try to drill with it like that, best case you will get oversize holes.

Worst case you will break the drill! (Always start a drill with either a Centre Drill or a Spotting Drill )

As Jason says, find the capscrews and adjust them to bring the two centres into alignment.

When they look to be OK, trap a thin piece of steel between then, so that it is horizontal.

When it lies exactly square across the lathe, the centres are aligned. If it is at an angle, adjust the two capscrews until it is. Lock the two capscrews against each other so that the steel is still square across the lathe.

Eventually, you will be able to make up, or buy, and alignment bar and set the Tailstock with the bar between centres with a dial indicator.

You can buy cutting tools, and drill chucks, and suitable arbors from any of the usual suppliers, such as Arc EuroTrade, Warco, Chester, Axminster, RDG, Chronos etc.

As a newbie, I would suggest starting with High Speed Steel tools, which you can regrind to sharpen them.

The above suppliers will be able to supply in sets, if that is your wish, or you can buy individually.

This puts a bench grinder on the shopping list for the future.

FWIW, buy the largest that will fit your mini lathe, (Possibly 10 mm square? )and still need only a little shimming to bring up to centre height, NOT above. This will maximise rigidity.

It would be a good learning exercise to make yourself a Centre Height Gauge, and will provide you with experience and a tool which will save time and messing about setting up tools in the future.

A bit late for Santa to bring you some books, but the basic principles are set out in L H Sparey's "The Amateur's Lathe". Other useful books will be "The Amateur's Workshop" by Ian Bradley.

Neil Wyatt and David Fenner have both written books specifically about the mini lathe.

Another good reference book to mbuy is Tubal Cain's "Model Engineer's Handbook"

Before too long, you will need measuring equipment. Probably the first will be a calliper. Nowadays, most choose a digital one. A calliper will usually cover a range from 0 to 150 mm (0 – 6" in old money) and can changed from Metric to Imperial at the press of a button.

Dial or Vernier callipers, will be graduated in either or Metric or Imperial units, but do not have batteries that go flat at inconvenient times!

If you want, you can buy Micrometers, later.

Eventually you will find a need for Dial Indicators. (Certainly, if you have a four jaw chuck with the lathe.

3 Jaw chucks are ideal for holding round or hexagonal material. but for square, or irregular shapes, the 4 Jaw independant comes into its own. It also allows work to be brought on centre more accurately that most 3 jaw chucks can.

"Finger" types often have smaller graduations , but a shorter range, than Plunger types. (Typically 0.0005" graduations vs 0.001" for Plunger types ) Choose which sort of dimensions you will work in, probably Metrric, if your lathe is Metric, rather than Imperial.

You will need a base on which to mount the Indicator, and although a Scribing Block will do for some jobs, a Magnetic Base will probably be more useful. The ones with an adjustable linkage tend to be less rigid than those with this facility. For measurement, rigidity is essential to maximise accuracy, although the adjustable type make setting quicker and easier.

Then you will find a need for taps and Dies to produce external and internal threads.

Probably a Metric set would be a good starting point. Whitworth, BSF or Unified are only likely to be needed if you get involved in restoring older Cars, Motorcycles or machines.

Finally, ask questions on here, some VERY expert and skilled folk who will help you.

Find a Model Engineering Club near you and join. There you will find like minded enthusiasts who will answer questions face to face and even demonstrate how to do jobs.

End of long ramble.

Howard

Dr. MC Black.